p

WARNING! Ensure you have read and understand

Section 1 Safety Instructions.

4.1.

The pump may be use in any position from horizontal to vertical. When not horizontal ensure the hose

end of the pump is down.

4.2.

To use the pump, close valve (fig. 1.A) by turning the knob clockwise and pump the the handle up and

down to apply the load.

4.3.

To release pump pressure, turn knob anti-clockwise (B).

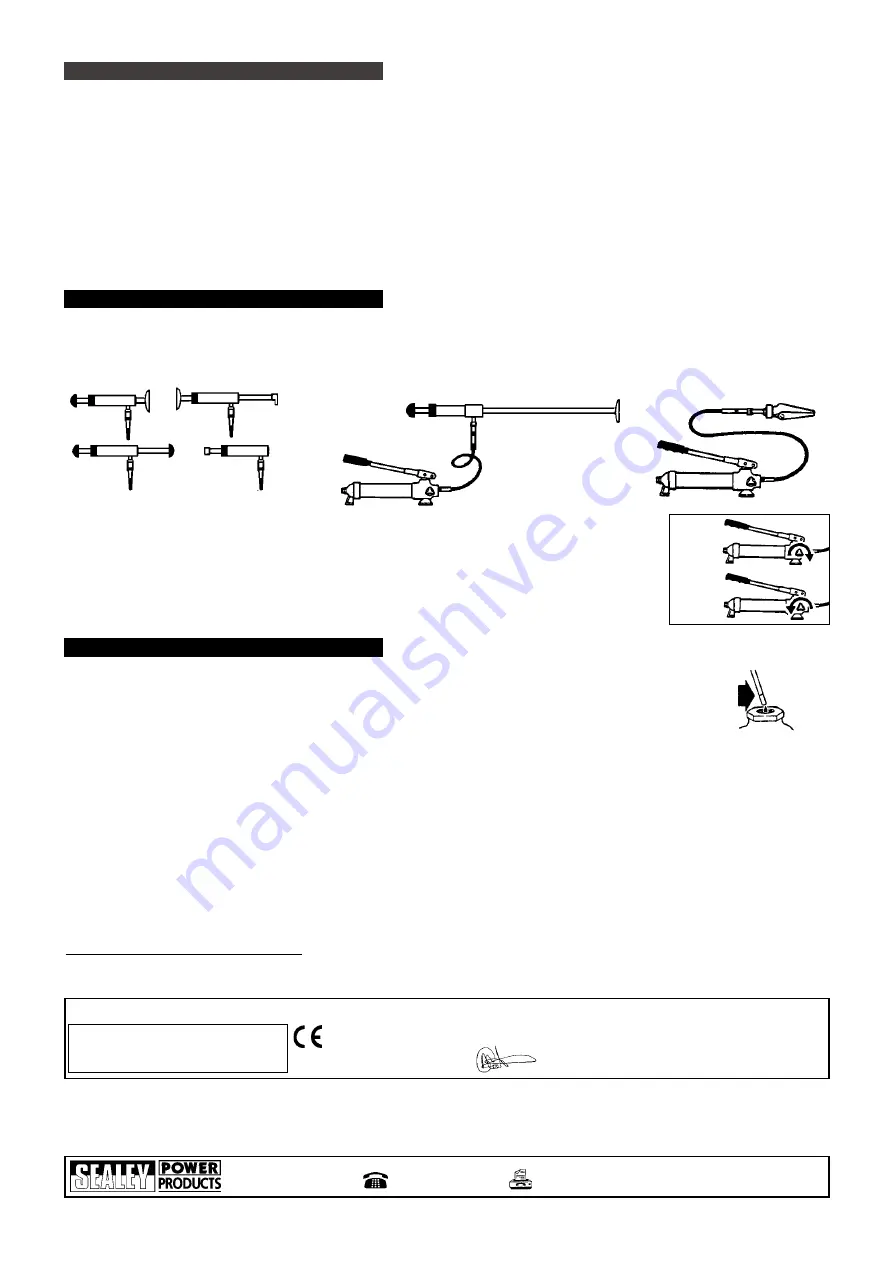

Illustrated below are the main attachment variations.

Ensure the task you are undertaking falls within the capacity of the pump and accessories you are using.

To provide maximum versatility a combination of ram accessories may be used.

3. INTRODUCTION

4. INSTRUCTIONS FOR USE

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF THE PUMP AND/OR RAM.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

DO NOT RETURN PUMP OR RAM TO US.

Please call us on 01284 757500 to obtain the address and telephone number of your local agent.

If product is under guarantee please contact your dealer.

5. MAINTENANCE

IMPORTANT:

Only fully qualified personnel should attempt maintenance or repair of the hydraulic system.

5.1. Pump oil level

Release pressure and disconnect the ram from the pump.

Hold pump in an upright position.

Remove filler plug and add hydraulic oil until it is level with the full mark (fig. 2).

p

WARNING: DO NOT

use brake fluid, or any fluid other than hydraulic jack fluid, as this may cause serious damage to the pump/ram

and will invalidate the warranty! Use only Sealey hydraulic oil.

5.2. General

Before each use check for broken, cracked, bent, or loose parts, or any visible damage to welds, ram, pump, hose and accessories.

If any suspect item is found, remove from service and take necessary action to remedy the problem.

Replace/repair with

genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Keep all parts of the kit clean.

5.3. De-commissioning hydraulic pump/ram

Should the pump or ram become completely unserviceable draw off the oil into an approved container and dispose of the product and the

oil according to local regulations.

Declaration of Conformity

We, the sole importer into the UK, declare that the product listed below is in conformity with the following standards and directives.

S

S

N

N

A

A

P

P

SNAP

BODY REPAIR KIT

Model: RE97/10C

98/37/EC Machinery Directive

4th November 2000

Signed by Mark Sweetman

The construction file for this product is held by the Manufacturer and may be inspected, by a national

authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into

the UK of Sealey Power Products.

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500

E-mail:

sales@sealey.co.uk

01284 703534

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

RE97/10C - 0008 - (1) - 011200

Kit features heavy gauge snap-together pipe-work and cast snap-together attachments compatible with most leading makes of snap-together

equipment. Hydraulic ram is capable of a thrust of 10 tons.

IMPORTANT:

Only fully trained and qualified persons should use this equipment. It is important that the user understands the applications, limitations and

potential hazards of the equipment.

VEHICLE DAMAGE INTRODUCTION

Before using the repair kit, you must determine the extent of vehicle damage. Check all parts and determine whether there are any broken, torn,

crumpled, wrinkled, crushed, twisted or bent metallic parts. Measurements should be taken to see how far the vehicle is out of alignment. It is

important to determine correct dimensions by referring to the manufacturers frame dimension charts and specifications. Remember, do not

commence pushing until you are sure when to stop. Take time to examine and determine damage correctly. Comprehensive planning will save

you time when using the equipment.

A

fig. 1

fig. 2

B