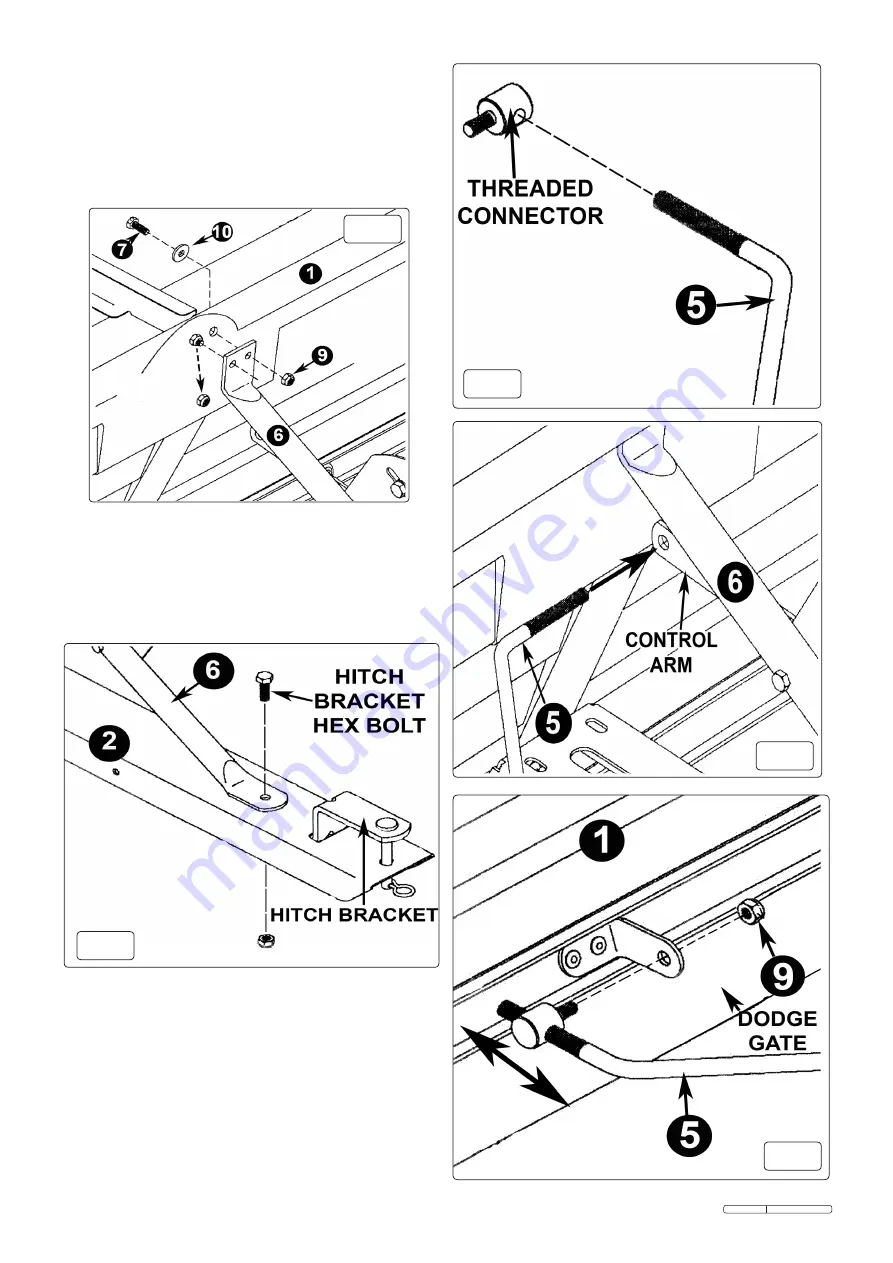

4.7. remove the hex bolt and nut securing the hitch bracket to the

hitch tongue (2). align the loose end of the flow control handle

over the hole and attach to the hitch tongue (2) using the hitch

bracket hex bolt and lock nut as shown in figure 4.

4.8. adjust the position of the flow control handle until it is aligned

with the hitch tongue and the hopper, then fully tighten all the

nuts and bolts used to secure the flow control handle.

4.9.

noting its position on the connecting rod (5), remove one of

the threaded connectors, as shown in figure 5.

4.10. feed the connecting rod (5) through the hole in the control

arm on the flow control handle (6) as shown in figure 6, until

the connecting rod is central in the control arm.

4.11. reattach the threaded connector removed in 4.9. back into its

original position on the connecting rod (5) .

4.12. attach the threaded connectors to the dodge gate brackets on

the hopper (1) using lock nut M6 (9) as shown in figure 7.

Do not over tighten the nuts to allow movement of the flow

control handle mechanism and dodge gate. the position and

range of movement of the dodge gate can be altered by

equally adjusting the threaded connectors up or down the

threaded portions on the connecting rod (5).

Original Language Version

sPD80t Issue: 1 - 21/06/11

4.4.

remove the top lock nut from the front of the hopper (1) as

shown in figure 3.

4.5.

align the top left hand hole of the flow control handle (6) with

the protruding bolt and loosely reattach the lock nut

previously removed in 4.4.

4.6

attach the right hand hole of the flow control valve (6) to the

hopper (1) using hex bolt m6x16 (7), big flat washer Ø6 (10)

and lock nut m6 (9). Do not fully tighten the nuts and bolts at

this stage.

fig.3

fig.5

fig.6

fig.7

fig.4