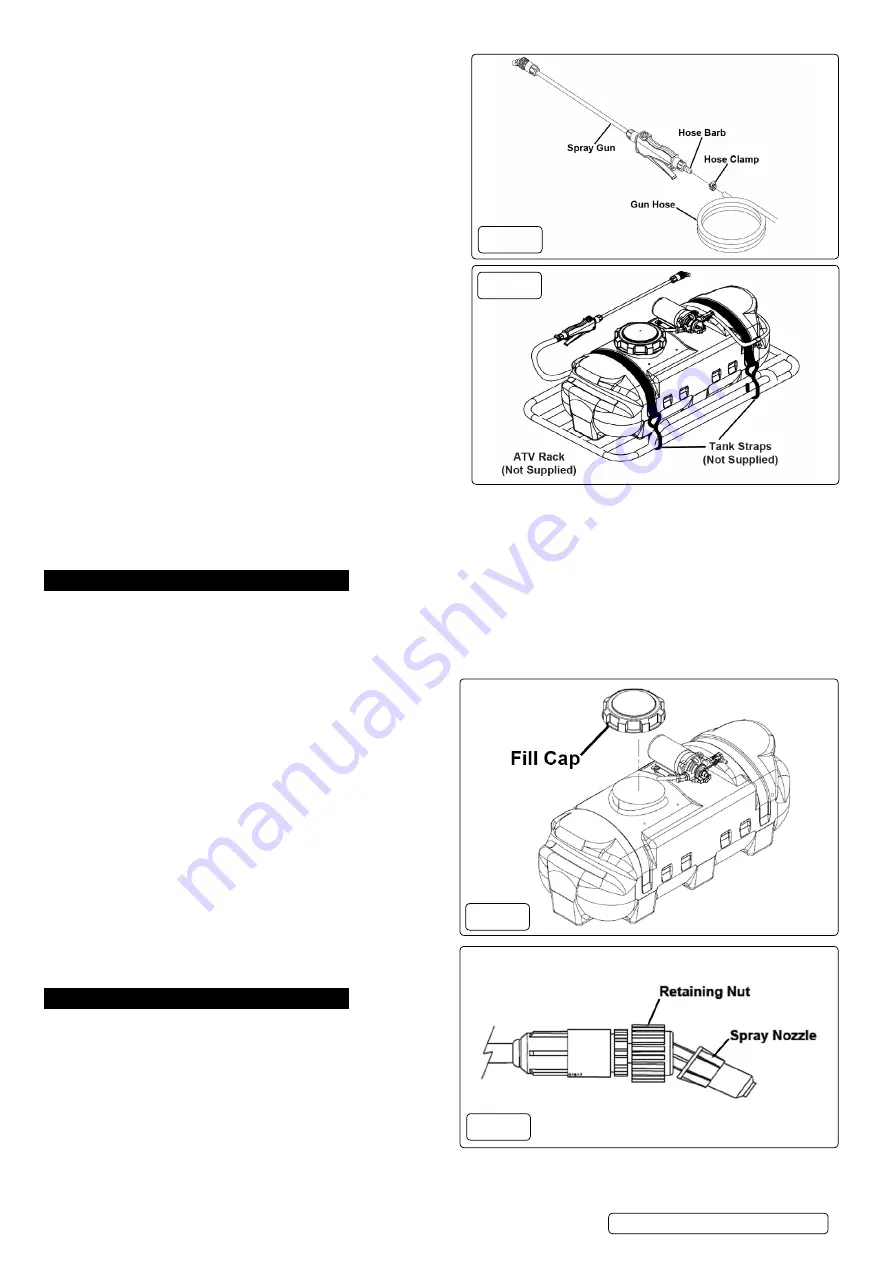

fig.6

5.5.

Attach Hose to Spray Gun (see fig.6)

5.5.1.

Slide the hose clamp over the hose.

5.5.2.

Push the hose onto the hose barb on the spray gun.

5.5.3.

Slide the hose clamp around the hose barb and tighten.

5.6.

Attach the Sprayer to the Vehicle (see fig.7)

5.6.1.

Use hooked straps (not supplied) to secure each end to an

ATV rack (not supplied). Sealey Flat bungee cord Set, Part

no: bcS15 is ideal for the job. For maximum security, order

two sets.

5.7.

connect the Remote Switch to battery

5.7.1.

disconnect the vehicle’s earth cable from the negative battery

terminal.

5.7.2.

connect the red positive clamp to the positive (+) terminal on

the battery.

5.7.3.

connect the black negative clamp to the negative (-) terminal

on the battery.

5.7.4.

Reconnect the vehicle earth cable.

5.8.

connect the Remote Switch to the Pump

5.8.1.

ensure the remote switch is in the oFF position (o).

5.8.2.

connect the remote switch to the power cable leading from the

rear of the pump.

Note:

The power cables will only connect one way.

5.9.

testing

5.9.1.

check that the gun clip screws are tight, hose clamps are

secure, and tank straps are properly fastened.

5.9.2.

While it is unlikely that factory-assembled components will

become loose, they should also be checked to make sure that

they are tight.

5.9.3.

Fill the tank with water and test the system for leaks.

5.9.4.

connect the remote switch to the pump power cord and turn the remote switch on. The pump is an “on demand” pump. When turned on,

the pump will prime itself, then turn off. When the gun trigger is squeezed, the pump will automatically start.

5.9.5.

operate the spray gun by squeezing the gun trigger.

5.9.6.

check for leaks throughout the system. If a leak is detected, fix the leak and re-test the system with water until no leaks are detected.

6. preparatioN

6.1.

preparation

6.1.1.

ensure the sprayer is securely attached to the vehicle.

6.1.2.

ensure the sprayer has been thoroughly flushed and drained of all residual agents from prior uses.

6.1.3.

clean the suction strainer of any agents residue. It is important to clean the suction strainer before each use to ensure it is not clogged

and to prevent residual agents from contaminating sprayer contents.

6.2.

environment considerations

6.2.1.

The sprayer should not be used when wind is in excess of 4mph.

6.2.2.

consideration should be given to members of the public and/ or

colleagues when spraying, ensure the area to be sprayed is well

ventilated and cordoned off.

6.3.

filling the sprayer

6.3.1.

choose an outdoor, well-ventilated area away from

unprotected people, animals, food, and other items that

might become contaminated.

6.3.2.

Wear personal protective equipment.

6.3.3.

Turn off power to the sprayer before filling. The vehicle

should also be off, with wheels chocked to prevent unintended

movement.

6.3.4.

Remove the fill cap located on top of the sprayer. (fig.8).

6.3.5.

before filling ensure drain cap is securely tightened.

6.3.6.

mix agents as instructed on that particular product.

Do Not

mix more than needed, to reduce wastage and the need to

store excess agents.

6.3.7.

Pour agent through the filler cap. When done replace filler

cap and tighten.

7. operatioN

7.1.

personal protective equipment

7.1.1.

ensure personal protective equipment is used. i.e gloves,

goggles, coverall and breathing mask.

7.2.

turn on power

7.2.1.

Turn the remote switch to the on (I) position.

7.3.

spray Gun (see fig.9)

7.3.1.

Remove gun from lance clips. To spray, squeeze the gun trigger.

7.3.2.

Twist the spray nozzle to change from a straight stream to a

cone spray pattern. check with the agent manufacturers label

which is best to use.

Note:

ensure that the trigger is not squeezed when adjusting the spray pattern.

7.4.

Leaving unattended

fig.7

fig.8

fig.9

SS37 | Issue 4 (HF) 03/04/18

Original Language Version

© Jack Sealey limited