3. SPECIFICATION

Model No: ................................................ SUPERMIG275.V2

Welding Current: .......................................................40-270A

Wire Capacity:............................................................. 5-15kg

Duty Cycle: ........100% @ 112A, 60% @ 146A, 20% @ 255A

Cooling System: .....................................................Forced Air

Spot Welding Timer: ......................................................... Yes

Gas Type:.................................. CO2, Argon, CO2/Argon Mix

Torch: ............................ 3m Euro Non-Live - BINZEL® MB24

Supply: ....................................................................230V-55A

Absorbed Power: ....................................................... 12.6kW

Case Size: ......................................................... Extra-Large

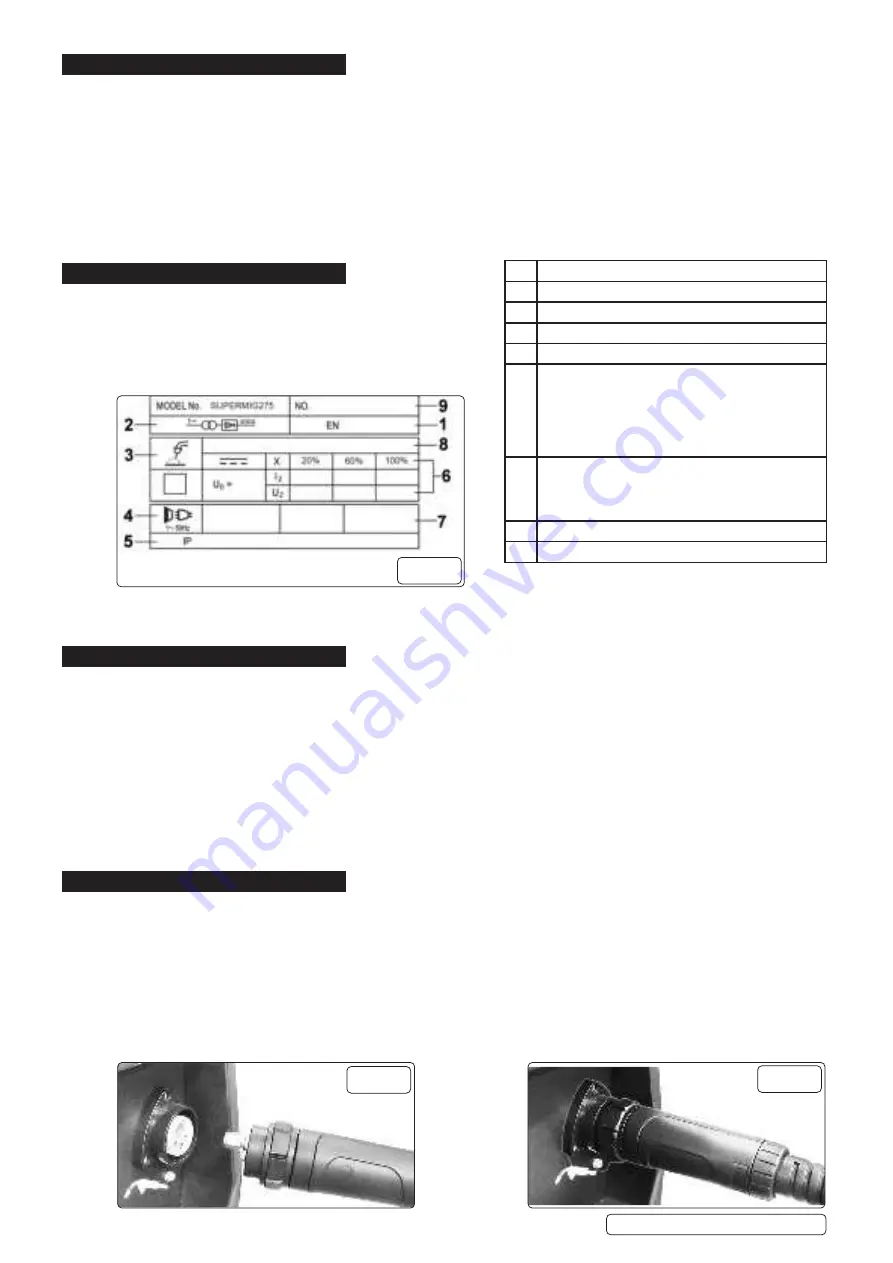

4. RATING PLATE

Detailed technical data relative to the performance of the machine

is located on the back panel.

NOTE:

The ratings plate detailed below (fig.1) is an example only

intended to assist with the explanations of the symbols. To determine

the correct technical values of the machine refer to the data plate on

your machine and the specification table above.

5. CONTENTS

5.1.

UNPACKING

5.1.1.

Unpack the product and check contents. Take care to ensure safety when removing product from it’s packaging. Seek assistance

from another person as the welding unit is heavy. Should there be any damaged or missing parts contact your supplier

immediately.

5.2.

CONTENTS

Main Welding Unit.

Wire Feed Roller 0.8mm/1.0mm x 1.

Torch & Cable with Euro connector.

Welding Tip 0.8 and gas cap.

Earth Clamp Cable.

Industrial Gas Regulator.

Gas Bottle Retaining Chain.

6. ASSEMBLY

NOTE:

The welding set is supplied with the wheels and handles fully assembled.

6.1.

CONNECT WELDING SET TO THE MAINS POWER SUPPLY

6.1.1.

Before making any electrical connections, ensure that the mains voltage and frequency of the supply matches the electrical

specification of the welding set as stated on the welding set’s rating plate (fig.1).

6.1.2.

The welding set must only be connected to a 30 Amp fused power supply as described in section 1.

6.1.3.

Refer to the section on electrical safety at the start of these instructions for information on the correct connection of the mains power

plug.

6.2.

CONNECT TORCH “Euro Connection”

6.2.1.

The welding set is fitted with a “Euro Connection” quick release torch. Line up the pins in the torch connector with the appropriate

holes in the socket on the front panel connector (fig.2), push in, engage and tighten the locking nut (fig.3).

Supermig275.V2 Issue 1 10/01/22

Original Language Version

© Jack Sealey Limited

1

Relevant standard

2

Single phase transformer - rectifier

3

Welding with a continuous flow of welding wire

4

Single-phase AC supply

5

Case protection class

6

Output

U0: Rated maximum and minimum no load voltage

I2,U2: Current and corresponding voltage

X: Welding ratio based on a 10 minute cycle

20% = 2 minutes welding 8 minutes rest

100% = continuous welding

7

Mains supply

U1: Rated suply voltage and frequency

I1 max: Maximum current

I1eff: Maximum effective current

8

Welding current range

9

Serial number

fig.1

fig.2

fig.3