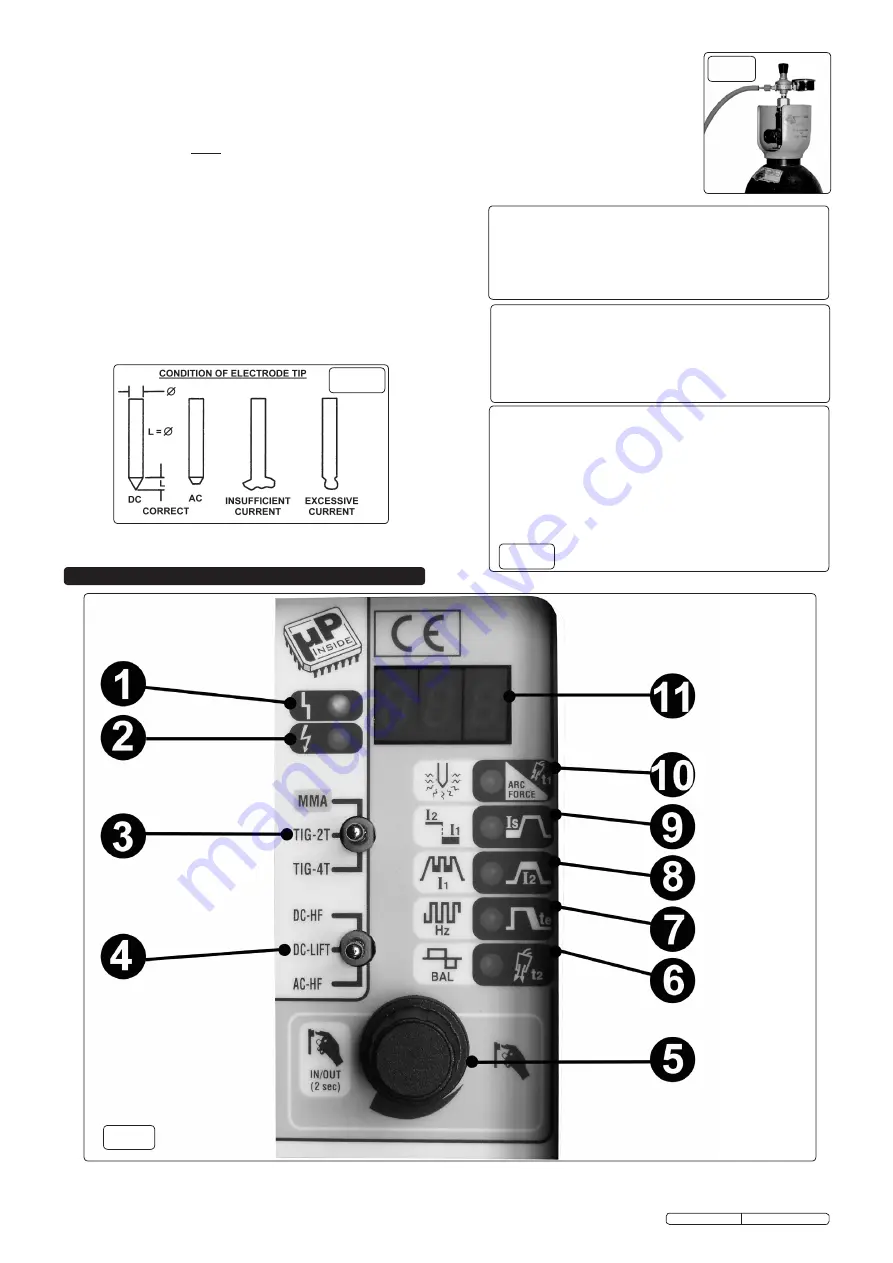

4. CONTROL PANEL

3.8

PREPARATION AND CHOICE OF ELECTRODE.

In order to produce a good

weld it is important to choose an electrode of the correct diameter for the current

to be used. For a general guide to the settings to be used with particular

diameters of electrodes please refer to the adjacent tables. The electrode will

normally protrude from the ceramic nozzle by 2 to 3mm but in order to gain

access to inaccessible areas such as internal corners the electrode can be made

to protrude by up to 8mm. The chosen electrode should be sharpened axially on

a grinding wheel as indicated in the diagram below. The tip should be

perfectly concentric in order to avoid arc deviations. The condition of the

electrode should be regularly inspected to maintain it in peak condition.

3.9

PREPARATION OF THE WORKPIECE.

For a good weld it is important that the

workpiece is thoroughly cleaned so that no oxides, oil, grease or solvents remain

on the surface of the material.

fig 7

TIG WELDING PARAMETERS FOR STAINLESS STEEL (DC)

Thickness Current Electrode

Nozzle

Argon Filler Rod

(mm)

( A )

(diam mm) (diam mm) ( L/min ) (diam mm)

0.3 - 0.5

5 - 20

0.5

6.5

3

---

0.5 - 0.8

15 - 30

1

6.5

3

---

1

30 - 60

1

6.5

3 - 4

1

1.5

70 -100

1.6

9.5

3 - 4

1.5

2

90 - 110

1.6

9.5

4

1.5 - 2.0

3

120 - 150

2.4

9.5

6

2 - 3

4

140 - 190

2.4

9.5 - 11

5 - 6

3.0

TIG WELDING PARAMETERS FOR DEOXIDATED COPPER (DC)

Thickness Current Electrode

Nozzle

Argon Filler Rod

(mm)

( A )

(diam mm) (diam mm) ( L/min ) (diam mm)

0.3 - 0.8

15 - 60

0.5 - 1

6.5

4

---

1

50 - 100

1.0

9.5

6

1.5

1.5

30 - 60

1.6

9.5

8

1.5

2.0

70 - 100

1.6

9.5

8

1.5

TIG WELDING PARAMETERS FOR ALUMINIUM (AC)

Thickness Current Electrode

Nozzle

Argon Filler Rod

(mm)

( A )

(diam mm) (diam mm) ( L/min ) (diam mm)

1

30 - 40

1 - 1.6

6.5

4 - 6

1.2 - 2

1.5

60 - 85

1.6

9.5

4 - 6

2

2

70 - 90

1.6

9.5

4 - 6

2

3

110 - 160

2.4

11

5 - 6

2

3.7 CONNECTING THE GAS

3.7.1 When using Argon gas fit the Bull Nose Adaptor supplied, to the cylinder with a spanner.

3.7.2. Fit the gas regulator onto the Bull Nose Adaptor (see fig.6).

3.7.3 Using the clear tubing supplied connect the regulator to the gas inlet on the back of the inverter (see fig.5a - 3). Hold the

tubing securely in place on each connector by using the worm drive clamps supplied.

3.7.4 Open the regulator before opening the cylinder valve. Test for leaks.

3.7.5. Set the gas flow to suit the welding parameters required. See WELDING PARAMETER TABLES below for general guidance.

3.7.6 If necessary the gas flow can be adjusted during welding using the regulator knob.

fig 6

fig 8

Original Language Version

TIG161HFACDC Issue: 1 - 03/11/11

fig 9