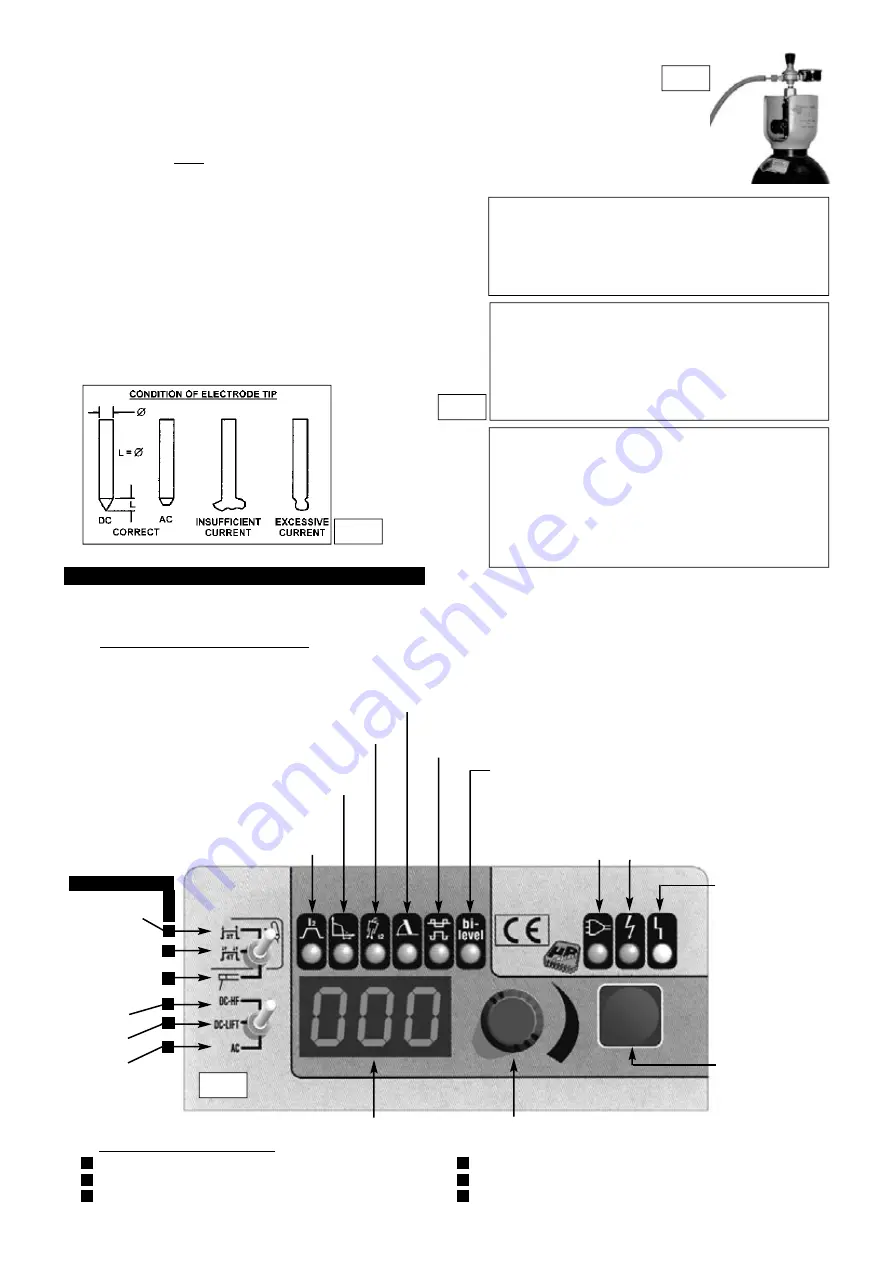

4. CONTROL PANEL

4.0

The TIG175/HF is microprocessor controlled allowing the setting of a high number of parameters enabling the operator to make an optimal weld under

most conditions and with most materials. When the machine is switched off the last active parameters are retained and recalled when the machine is

switched on again.

4.1

SELECTION OF WELDING PARAMETERS.

4.1.1 The 6 main welding parameters are grouped above the main LED display and each symbol has an associated single LED. Use the parameter selection

button to the right of the knob to step through the parameters until you reach the one you wish to adjust. The parameter is active when the LED below the

symbol is illuminated. The value to be adjusted will appear in the main display. Adjust the value by using the rotary encoder knob to the right of the display.

4.2

SELECTION OF WELDING MODES.

Use the two miniature toggle switches on the left hand side of the control panel to select the required welding mode.

TIGAC 2 step weld cycle . . . . . . . . . . . . . . . . .see section 5.6.1

TIGAC 4 step weld cycle . . . . . . . . . . . . . . . . . . . .see section 5.6.2

ARC welding with stick electrode . . . . . . . . . . . . .see section 7.0

DC HF start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see section 6.7

DC Lift start . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see section 6.8

AC Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see section 5.9

ALARM CONDITION

(Yellow LED) See main

display for two types of

alarm as described below.

AL.1

Fault in primary

power supply; power

supply voltage is outside

the required range.

AL.2

One of the

safety thermostats has

cut in due to the

machine overheating.

The machine will return

to normal operation

automatically when

it has cooled down.

OUTPUT VOLTAGE

(Green LED)

POWER SUPPLY

VOLTAGE

(Green LED)

BI-LEVEL WELDING

Adjusts the level of the base current in relation to

the main current that has been set. Works only in TIG 4 step weld cycle.

Varies from a maximum value equal to the main current to a minimum value

equal to 30% of the main current To switch off the bi-level function turn the

encoder knob anticlockwise until the display shows off. See section 5.6.3

BALANCE

Sets a percentage ratio in TIG AC modes between the time that the current is

EN ( electrode negative ) and the period of the square waveform in AC operation. Setting

can vary between 20% and 90%. ( See section 5.7.1 and also fig.10 )

CURRENT DOWN SLOPE

This setting reduces the current gradually at the end of welding and can be varied from 0.1 to 10 seconds. ( See section 5.3 )

POST GAS TIME

Sets post gas time from 0.1 to 25 secs. See section 5.2

ARC FORCE

Regulates the value of the arc force current and only

applies to ARC welding with a stick electrode. Arc force is

expressed as a percentage of the welding current. See section 7.6

MAIN CURRENT

This setting is measured in AMPS and

can vary from 5 to 140 for ARC welding and 5 to 160 in

TIG DC or TIG AC. The value represents the average

welding current for DC and the effective welding current

for AC

TIG AC

2 step weld cycle

TIG AC

4 step weld cycle

ARC welding with

stick electrode

DC HF Start

DC Liftstart

AC Welding

ENCODER KNOB

for setting parameter values

MAIN DISPLAY

shows selected parameter values and alarm conditions

PARAMETER

SELECTION BUTTON

Steps through the

available parameters.

Single illuminated

LEDs indicate the

selected parameter.

3.6

PREPARATION AND CHOICE OF ELECTRODE .

In order to produce a good

weld it is important to choose an electrode of the correct diameter for the current

to be used. For a general guide to the settings to be used with particular

diameters of electrodes please refer to the adjacent tables. The electrode will

normally protrude from the ceramic nozzle by 2 to 3mm but in order to gain

access to inaccessible areas such as internal corners the electrode can be made

to protrude by up to 6mm. The chosen electrode should be sharpened axially on

a grinding wheel as indicated in the diagram below. The tip should be

perfectly concentric in order to avoid arc deviations. The condition of the

electrode should be regularly inspected to maintain it in peak condition.

3.7

PREPARATION OF THE WORKPIECE.

For a good weld it is important that the

workpiece is thoroughly cleaned so that no oxides, oil, grease or solvents remain

on the surface of the material.

fig 7

fig 9

TIG WELDING PARAMETERS FOR STAINLESS STEEL (DC)

Thickness Current Electrode

Nozzle

Argon Filler Rod

(mm)

( A )

(diam mm) (diam mm) ( L/min ) (diam mm)

0.3 - 0.5

5 - 20

0.5

6.5

3

---

0.5 - 0.8

15 - 30

1

6.5

3

---

1

30 - 60

1

6.5

3 - 4

1

1.5

70 -100

1.6

9.5

3 - 4

1.5

2

90 - 110

1.6

9.5

4

1.5 - 2.0

3

120 - 150

2.4

9.5

6

2 - 3

4

140 - 190

2.4

9.5 - 11

5 - 6

3.0

TIG

WELDING PARAMETERS FOR DEOXIDATED COPPER (DC)

Thickness Current Electrode

Nozzle

Argon Filler Rod

(mm)

( A )

(diam mm) (diam mm) ( L/min ) (diam mm)

0.3 - 0.8

15 - 60

0.5 - 1

6.5

4

---

1

50 - 100

1.0

9.5

6

1.5

TIG WELDING PARAMETERS FOR ALUMINIUM (AC)

Thickness Current Electrode

Nozzle

Argon Filler Rod

(mm)

( A )

(diam mm) (diam mm) ( L/min ) (diam mm)

1

30 - 40

1 - 1.6

6.5

4 - 6

1.2 - 2

1.5

60 - 85

1.6

9.5

4 - 6

2

2

70 - 90

1.6

9.5

4 - 6

2

3

110 - 160

2.4

11

5 - 6

2

3.5

CONNECTING THE GAS

3.5.1 When using Argon gas fit the Bull Nose Adaptor supplied, to the cylinder with a spanner.

3.5.2. Fit the gas regulator onto the Bull Nose Adaptor. ( see fig.6 )

3.5.3 Using the clear tubing supplied connect the regulator to the gas inlet on the back of the inverter ( see fig.5a - 3 ). Hold the

tubing securely in place on each connector by using the worm drive clamps supplied.

3.5.4 Open the regulator before opening the cylinder valve. Test for leaks.

3.5.5. Set the gas flow to suit the welding parameters required. See WELDING PARAMETER TABLES below for general guidance.

3.5.6 If necessary the gas flow can be adjusted during welding using the regulator knob.

fig 6

fig 8

TIG175HF - 1 - 061003

A

A

B

B

C

C

D

D

E

E

F

F

WELDING MODES