Original Language Version

TP200S Issue No:1 - 06/09/10

4.8

Set the controls for suction.

4.8.1

Turn the Suction/Discharge valve to the SUCTIoN position as shown in fig.3-10.

4.8.2

Set the air pressure on the incoming supply to between 72 and 100psi.

4.9.

Gradually open the air inlet valve on the unit.

(fig.3-2) Increase the vacuum down to -60cmHg until suction starts. Monitor the

vacuum in the tank using the pressure gauge (fig.3-7). The needle should remain in the green area on the left hand side of the

gauge (see fig.1).

4.10.

Turn the unit off.

When draining of the vehicle tank is finished turn the unit off by closing the air inlet valve (see fig.3-2).

4.10.1 Unless the fuel is to be returned to the vehicle immediately, it should be transferred to an approved container and stored in a

designated lockable, well-ventilated area, preferably outside the workshop.

fig.3

4.4.4.

Disconnect the carburettor’s fuel inlet pipe and push it onto the fuel line adaptor.

4.5.

Fuel-injected vehicles.

Fuel can be transferred from fuel-injected vehicles through the injector’s fuel inlet pipe.

4.5.1

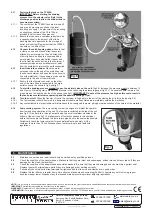

Use connector type ‘B’ (see fig.2). Choose the required diameter. See fig.4B.

4.5.2

Screw the adaptor and washer into the quick coupling adaptor (fig.2) and then into the adaptor hose.

4.5.3

Plug the male fitting on the other end of the adaptor hose into the quick connector main hose. See fig.2.

4.5.4

Plug the male fitting on the other end of the main hose into the quick connector directly below the gauge. See fig.2 and fig.3-5.

4.5.5

Disconnect the vehicle’s fuel inlet pipe coming from the tank and slide the ‘banjo’ fitting onto the adaptor.

4.5.6

Use the two gaskets from the ring removed from the car to obtain a good seal.

4.6

Transferring fuel directly from a vehicles fuel tank.

4.6.1

Connect one of the 5 probes to the metal extension tube as shown in fig.2.

4.6.2

If the vehicle is fitted with an anti-theft device at the fuel tank inlet, access to the tank may be gained from the boot through a

porthole, closed by a guard or a safety device. Remove the guard, and the relevant cap and insert the probe into the hole. This will

allow quicker transfer of fuel than the previous two methods.

4.6.3

In older vehicles, the probe can be inserted directly into the fuel tank through the fuel tank inlet.

4.6.4

Insert the fume return pipe into the same opening as the collection probe. See fig.2.

4.7.

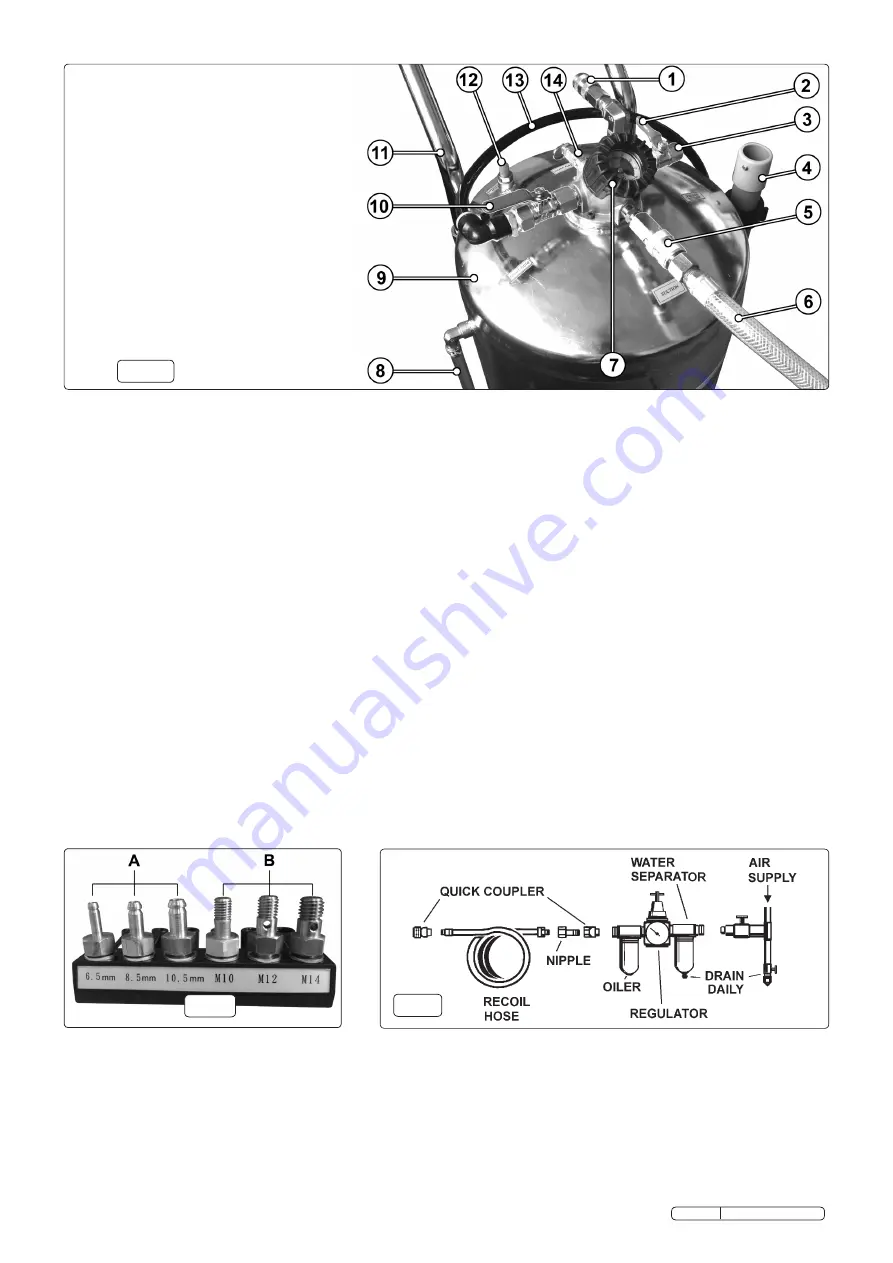

Connect the workshop air supply.

Recommended hook-up procedure is shown in fig.5 below.

4.7.1

Ensure the air inlet tap (fig.3-2) is oFF before connecting to the air supply.

4.7.2

You will require an air pressure of 72 -100psi, and an air flow of 12cfm.

4.7.3

WARNING!

Ensure the air supply is clean and does not exceed 100 psi while operating the drainer. Too high an air pressure and

unclean air will shorten the product life due to excessive wear, and may be dangerous causing damage and/or personal injury.

4.7.4

Drain the air tank daily. Water in the air line will damage the air motor.

4.7.5

Clean air inlet filter weekly.

4.7.6

Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should

be 1/4” I.D. and fittings must have the same inside dimensions.

4.7.7

Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

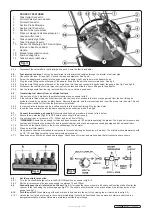

PRODUCT FEATURES

1.

Tank outlet Connector.

2.

Air Inlet Valve (shown closed).

3.

Air Inlet Connector.

4.

Suction Probe Stowage.

5.

Suction Inlet Connector.

6.

Suction Tube (connected).

7.

Pressure Gauge (indicates pressure or

vacuum within tank.)

8.

Tank capacity sight tube.

9.

Tank (Pressure Vessel.)

10. Suction IN/ Discharge oUT Switch Valve.

(Shown in Suction position)

11. Handle.

12. Manual pressurisation valve.

13. Fume venting tube.

14. Tank pressure relief valve.

fig.4

fig.5