Original Language Version

TP200S Issue No:1 - 06/09/10

5.1

Maintenance, service and repair should only be carried out by qualified persons.

5.2

Check the condition of the transfer hoses. Make sure that they are intact and undamaged, without cracks, holes or leaks. If they are

damaged or they leak, replace them.

5.3

Check the condition of the adaptors and associated washers. Be sure that they are undamaged and can maintain a perfect seal.

Replace them with original spare parts if they are damaged or not working correctly.

5.4

Periodically check the earth strap terminals for tightness and that the wire and clamps are in good order.

5.5

Replace the fuel filter on a regular basis. Care should be taken when unscrewing the filter to capture any spilt fuel using rags or

absorbent paper towel. Dispose of any fuel soaked material according to local authority regulations.

5. MAINTENANCE

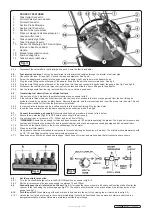

4.11

Draining the tank on the TP200S.

IMPORTANT. Before starting the draining

process turn the selector valve (fig.6) to the

discharge position to allow the drainer tank to

become pressurised.

4.11.1

The contents of the TP200S tank are drained off

using the air pressure supplied by the local

incoming air supply. The pressure of the incoming

air supply can remain at the 72 to 100psi

previously set for the suction process.

4.11.2 Ensure that you have a container ready that has

a capacity equal to the amount of fuel to be

discharged and is approved for the storage of

petrol or diesel fuel. Remember that the TP200S

can hold up to 40ltrs of fuel.

4.12

Connect the earth bonding straps.

Ensure that

a clamp on one end of each strap is securely

attached to a metal part on the unit. Attach the

other clip from one strap to a known earthing

point, away from any potential fuel vapour, and

the clip from the second strap to the container. If

necessary scrape away a small amount of paint

from the container to improve the earth connection.

4.13

Insert tube into container.

Place the metal

extension tube on the end of the main hose into

the chosen container and open the valve (lever in

line with metal tube). If necessary a probe can be

connected to the end of the metal tube.

4.13.1 Ensure that the female connector on the other

end of the main hose is connected to the male

outlet connector as shown in fig.6 and fig.3-1.

4.14

To start the draining process gradually open the air inlet valve on the unit.

(fig.3-2) Increase the pressure slowly to between 15

and 21psi until draining starts. Monitor the pressure in the tank using the pressure gauge (fig.3-7). The needle should remain in the

green area on the right hand side of the gauge (see fig.1).

IMPORTANT. Do not set the pressure too high as this could result in

the tank pressure relief valve operating and the possible venting of fuel.

4.15

Turn the unit off.

When the transfer of fuel to the container is finished turn the unit off by closing the air inlet valve (see fig.3-2).

4.15.1 The fuel container should be stored in a designated lockable, well-ventilated area, preferably outside the workshop.

4.15.2 Any contaminated fuel or petrol/diesel mixtures should be consigned to waste, giving a clear description of the nature of the material.

fig.6

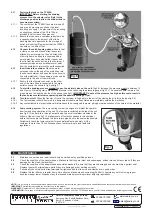

4.16

Fume venting system.

The fume venting system is designed to protect the operator

from fumes during operation of the unit. The fumes are collected at the top of the unit

(see fig.3-13) and are fed through a plastic pipe to a small container mounted at the

bottom of the unit (see fig.7). Small amounts of fuel will condense in this container

before the fumes are fed through the fume return pipe back to the source tank/vehicle.

Periodically check the fume container for accumulated fuel and empty it if the

container is more than 1/3 full. Dispose of any fuel according to local authority

regulations.

fig.7

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park

,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web