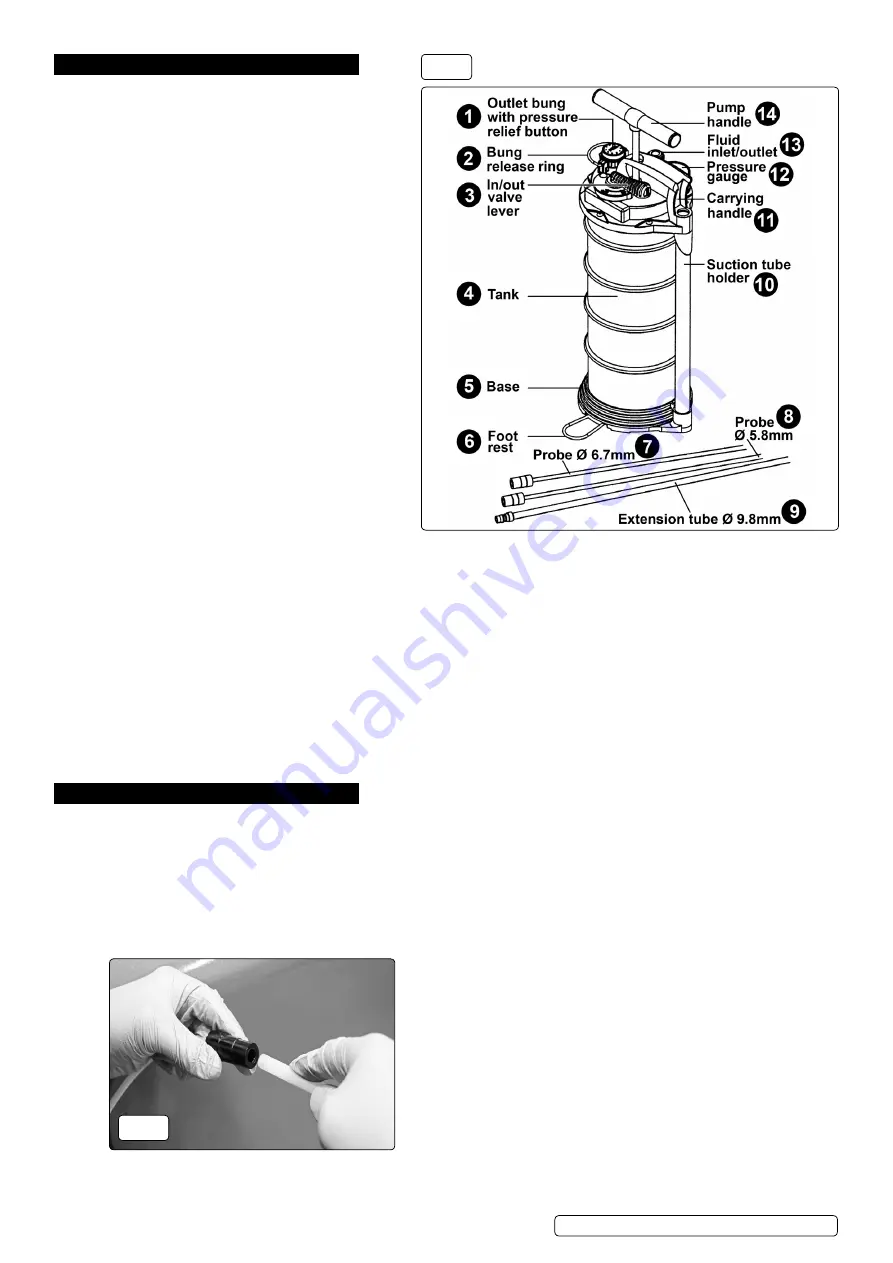

4. MAIN FEATUREs

Features

Refer to fig.1

4.1.

OUTLET BUNg

The outlet bung is inserted into a small

spout in the top of the unit which is used to manually

empty oil out of the tank. The bung has an integral

pressure relief button built into it. Press the button

downwards into the bung and hold it there until the

pressure has equalised.

4.2.

BUNg RELEAsE RINg

To remove the bung take hold of

the bung release ring and turn the bung anti-clockwise

until it stops. Pull upwards to remove the bung. To lock the

bung in place insert it into the spout and turn it clockwise

until it stops. The hooks on either side of the bung should

now be trapped under the flanges on either side of the

spout.

4.3.

IN/OUT VALVE LEVER

When the valve lever is moved

to the ‘In’ position, operating the pump handle creates

a vacuum, causing fluid to be sucked into the tank

via the probe/extension tube. When the valve lever

is moved to the ‘oUT’ position, operating the pump handle

pressurises the tank causing fluid to be expelled from the

tank.

4.4.

TANk

After the unit has been used the tank should not be

left in either a vacuum or pressurised state. Push in the

pressure relief button and hold it down until the pressure

has equalised.

4.5.

BAsE

The base should be placed on a smooth level

surface during operation.

4.6.

FOOTREsT

When extra stability is required during

pumping fold out the footrest from underneath the base.

4.7.

PROBE Ø6.7

This is the larger of the two probes provided and is intended for insertion into the dipstick tube of vehicles where an oil

change is required. The red plastic fitting on this tube is a push fit onto the extension tube.

4.8.

PROBE Ø5.8

This is the smaller of the two probes provided and is intended for insertion into the dipstick tube of vehicles where an oil

change is required. The black plastic fitting on this tube is a push fit onto the extension tube.

4.9.

EXTENsION TUBE Ø9.8

The fitting at one end of this tube fits directly into the Fluid inlet/outlet ‘13’. one of the probes will be a push fit

onto the other end of this tube.

4.10.

sUCTION TUBE hOLDER

The extension tube and the two probes can be stored here when not required.

4.11.

CARRYINg hANDLE

The pump handle should be in the down position to use the carrying handle.

4.12.

PREssURE gAUgE

The needle moves anti-clockwise from zero when a vacuum is created to suck fluid into the tank. The needle moves

clockwise from zero when the tank is pressurised to expel fluid from the tank. If the needle moves into the red zone the excess pressure

will be automatically released.

4.13.

FLUID INLET OUTLET

This fitting has a sliding sleeve which has to be pulled downwards before the fitting on the end of the extension

tube will go in.

4.14.

PUMP hANDLE

The pump handle should be moved up and down through its full stroke for most efficient operation of the pump. If the

pump handle locks up this means the tank is full. Press the pressure relief button to free the handle.

5. OPERATION

5.1.

sET UP FOR OIL ChANgE

NOTE:

ensure you read, understand and apply the Section 1 Safety Instructions and consult manufacturer’s workshop manual for any

specific procedures.

5.1.1.

ensure that the vehicle is level. Run the engine for approximately five minutes to ensure that the oil is warm. Switch off engine.

5.1.2.

Remove the oil dipstick from the engine.

5.1.3.

Insert the appropriate extracting probe into the dipstick tube making sure it reaches the bottom of the sump. Connect the extracting probe

to the extension tube using the black or red soft plastic adaptor. The tubes are a push fit into the adaptor (fig.2).

5.1.4.

Position the extractor close to the front or side of the vehicle. Plug the extension tube fitting into the fluid inlet/outlet fitting on top of the

extractor (see fig.1-13).

Original Language Version

© Jack Sealey limited

fig.2

fig.1

TP6905.V2, TP6906.V2 Issue:3 (3) 26/04/19