5. MAINTENANCE

WARNING!

With the exceptions listed below, all pump and electrical cable service maintenance and repair must be undertaken by an

authorised service agent only. Failure to observe this rule may be dangerous and will invalidate your warranty.

WARNING!

Ensure that the pump is disconnected from the mains power supply before attempting any service or maintenance.

NOTE:

The pump’s filter should only be cleaned out when necessary, as cleaning will simultaneously wash out the micro organisms

which help to keep the pond healthy. However, it should be cleaned whenever there is a noticeable deterioration in pump performance.

5.1.

CLEANING THE FILTER SPONGE

5.1.1.

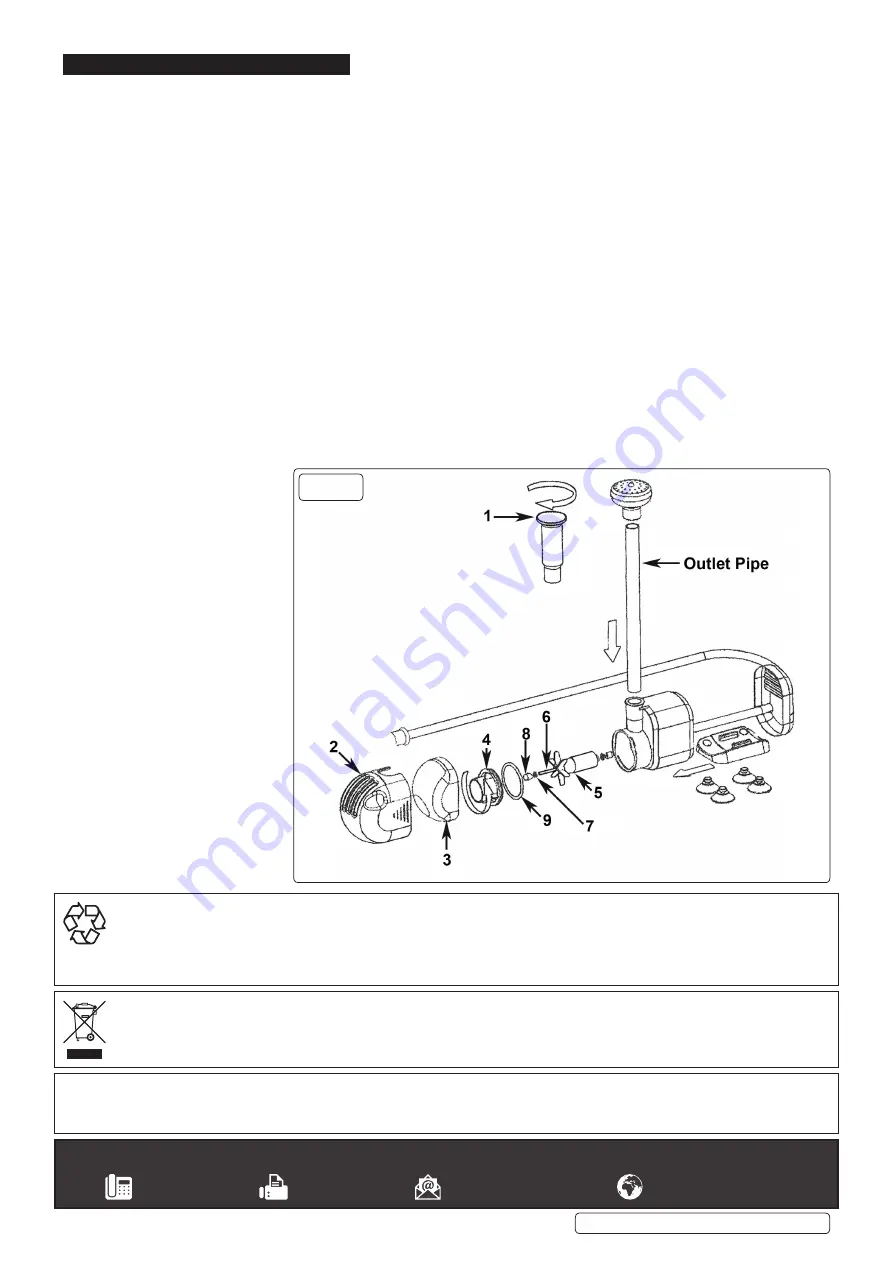

Press the filter housing together on both sides (fig 2.2) and pull off the cover.

5.1.2.

Remove the sponge filter (fig 2.3) from the housing and clean with clean cold water.

IMPORTANT:

Never use the pump without the filter in place as this could lead to damage to the pump.

5.2.

CLEANING THE FUNCTIONING PARTS

5.2.1.

Open the pump chamber lid (fig 2.4) by twisting it anti-clockwise a quarter turn and pulling it clear of the pump body.

5.2.2.

Remove the magnetic impeller (fig 2.5) carefully from the shaft. As this is done the magnetic force of the impeller must be overcome.

8

DO NOT

use any implements to remove dirt from inside the pump, but simply wash it out with lukewarm water.

5.2.3.

Use a soft sponge to remove any dirt deposits.

5.2.4.

To reassemble the pump carefully slide the magnetic impeller onto the shaft. At a certain point, the impeller will be drawn into the

housing by the magnetic force.

5.2.5.

Check that the ceramic washer (fig 2.7) and rubber bearing (fig 2.8) at both ends of the shaft are correctly mounted.

5.2.6.

Before closing the pump chamber with the lid (fig 2.4) make sure that the o-ring (fig 2.9) is correctly seated.

5.2.7.

Plug the supply cable into the mains supply briefly

(no more than 3 seconds)

to check that the impeller turns freely. A certain level of

noise is inevitable during this dry run. This is no cause for concern. When it is used in water, the pump should operate silently.

5.3.

WINTER STORAGE

5.3.1.

Place the pump in water filled vessel in a frost-free room. Storage in water prevents deposits from accumulating on the pump. If the

pump is stored dry, these deposits can block the impeller. If you wish to store the pump dry, you must ensure that the functioning parts

and filters have been thoroughly cleaned and dried.

WPP1100 | Issue 6 (H,F,2,3) 28/02/2019

Original Language Version

© Jack Sealey Limited

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500

01284 703534

sales@sealey.co.uk

www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

WEEE REGULATIONS

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

Note

: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

Important

: No Liability is accepted for incorrect use of this product.

Warranty

: Guarantee is 12 months from purchase date, proof of which is required for any claim.

fig.2