DO2 INSTRUCTIONS

Seametrics • 253.872.0284

Page 20 seametricscom

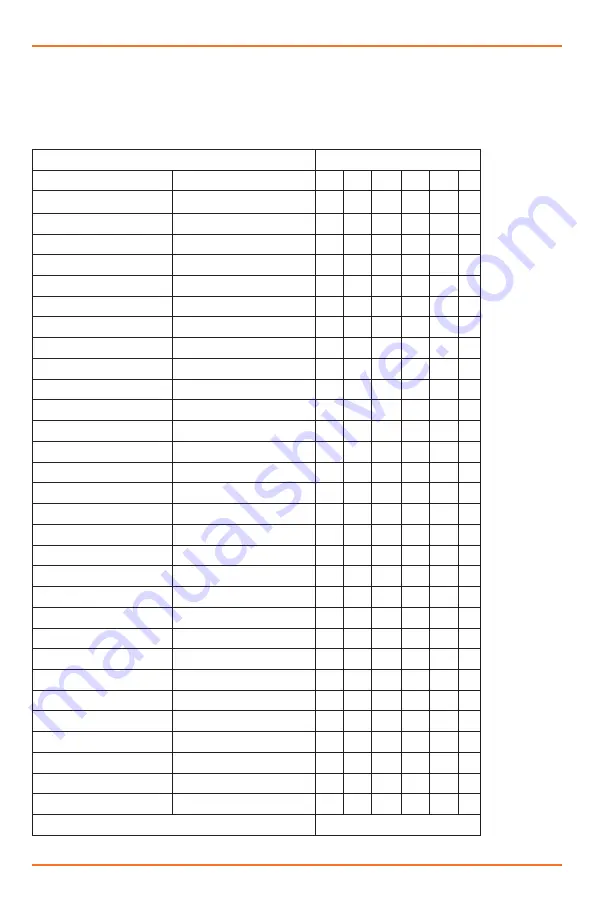

Any reading over 1000 indicates an error, as detailed in the chart below. To use this

chart, look up the 1000+ reading from your sensor and note the Sensor Error code

in the second column. Then note the Errors 0 – 5. See error descriptions after chart.

Errors

Aqua4Plus Reading

Sensor Error Code

5

4

3

2

1

0

1001

01

√

1002

02

√

1003

03

√

√

1004

04

√

1005

05

√

√

1006

06

√

√

1007

07

√

√

√

1008

08

√

1009

09

√

√

1010

10

√

√

1011

11

√

√

√

1012

12

√

√

1013

13

√

√

√

1014

14

√

√

√

1015

15

√

√

√

√

1016

16

√

1017

17

√

√

1018

18

√

√

1019

19

√

√

√

1020

20

√

√

1021

21

√

√

√

1022

22

√

√

√

1023

23

√

√

√

√

1024

24

√

√

1025

25

√

√

√

1026

26

√

√

√

1027

27

√

√

√

√

1028

28

√

√

√

1029

29

√

√

√

√

1030

30

√

√

√

√

Errors

APPENDIX D: ERROR CODE CHART

Summary of Contents for DO2

Page 2: ......