INPUTS/OUTPUTS and OPERATION

Battery Power.

The iMAG 4600 meter can come configured

with two replaceable 3.6V lithium ‘D’ batteries. In this

configuration, the only option/output is the scaled pulse

output which comes standard. The scaled output for the

battery powered option has a maximum frequency of 10Hz,

with a fixed pulse width of 10ms. Be sure to set your P value

such that the meter will function properly over the flow range

in your application.

See the tech bulletin on this topic for

more details.

The sample rate of the meter is user selectable

through the SAMP tab in the meter’s sub-menu. Sample

periods of 0.2, 0.33, 1, 3, 5, 15, 30, and 60 seconds can

be selected. Larger sample periods will yield longer battery

life but slower response time. Care must be taken to select

a sample period that us suitable for your application. See

the table on the next page for the expected battery life as a

function of sample period.

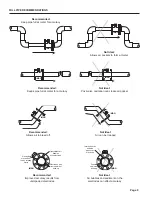

Pulse Output Connection.

When the second OID code

character is “P”, refer to the “

Digital Output Application”

diagrams on page 12 for recommended pulse output

connections to external equipment. Since this is an isolated

output, the external equipment must include a dc power

source to regenerate the pulse from the open-collector

output (transistor equivalent of a contact closure). A pull-up

or pull-down resistor may be needed if not included in the

user equipment as shown in the diagrams. Both the power

source and resistor may be supplied internally in some

types of control and monitoring devices. If not, as for most

PLC discrete input modules, they must be added externally

at the module input terminals. Pulse output rate in volume

units/pulse is user-settable via the SET P tab on the meter’s

setup menus.

Analog Output (4-20mA) Connection.

When the second or

third OID code character is “L” or “H”, refer to the “

Analog

Output Application”

diagram on page 12 for 4-20mA current

loop output connections to external analog input devices.

Since the meter’s analog output is isolated and passive, loop

power must be supplied externally as shown. (In addition, an

external resistor R

L

will be needed to convert the loop current

to voltage for voltage-only input devices.) The meter’s loop

transmitter minimum voltage drop is 6Vdc (8Vdc with HART)

which, with wiring resistance and loop power supply voltage,

will determine the maximum resistance for R

L

. The flow rates

corresponding to 4 and 20mA are user-settable via the SET

4 and SET20 tabs on the meter’s setup menus.

(Optional) Setup and Connection to a HART Network.

The

HART protocol, rev.7.5, allows for a Polling address of 0-63.

The default value in the iMAG is 0. To change the Polling

address, use iMAG menu HPOLL to set the Polling address.

To get to this menu, move to the EXIT tab and tap the

Hold

Tap

+

4 times. This will bring up another menu page

containing the tab HPOLL. Use the

Hold

Tap

+

to select the

Polling address.

A minimum of 250 ohms of loop resisitance must be present

in order for the HART modem to correctly and reliably

demodulate FSK voltage. With this in mind, the maximum loop

resistance* for the iMAG HART interface cannot be exceeded

in order to assure correct operation.

Use of HART Communicator.

The iMAG HART interface is

HART compatible. All the commands have been implemented

in accordance with the HART Protocol Specification published

by HART Foundation. A HART Communicator can be used with

the iMAG, even in the absence of DD files, by taking advantage

of the Generic Online Menu capability of a Communicator.

This means that a generic menu is automatically available

when DD files are not present.

The following information from the iMAG HART can be

displayed on the Communicator using the generic menu:

PV

Flowrate in units selected for iMAG

PV Loop Current

Loop current in mA

PV LRV

Lower range value of PV in units

selected for iMAG

PV URV

Upper range of PV in units selected for

iMAG

*4-20 mA loop has maximum loop resistance of 650ohms

and requires a 24Vdc power supply.

Battery Life/Sample Period

Sensor sample period(s)

(Seconds)

Expected battery life*

1/5 (0.2)

1 year

1/3 (0.33)

1.5 years

1

2.5 years

3

4 years

5

5 years

15

5.5 years

30

6 years

60

6.5 years

*Based on 75% battery capacity at room temperature with no option cards

installed. NOTE: If a large percentage of the meter’s life will be spent below

0.5 meters/second and above cutoff, battery life will be reduced.

Page 12

Summary of Contents for iMAG

Page 19: ...Page 17 NOTES...