CT2X INSTRUCTIONS

Seametrics • 253.872.0284

Page 22 inwusa.com

MAINTENANCE

Tips

• Never place a tool on the sensor body, it is very

thin and will deform causing leaks at o-ring seals

and potentially crushing the circuit board!

• Always twist the sensor body off the top cap

assembly rather than twisting the top cap assembly

off of the sensor body.

• For cabled sensors, always clamp the sensor on the

swaged area when applicable, the shoulder above

it will allow you to press down without the worry of

the sensor slipping out of the clamping device.

• If the sensor body is slippery or you are unable to

grip it hard enough to twist, try a piece of rubber

cabinet liner for additional friction.

There is a black, compressible square ring near the top of

the sensor. This ring acts as a spring to lock the cable in.

This needs to be compressed in order to allow removal

of the top cap. Once this ring is compressed, a gentle

counterclockwise twist is all that is needed to remove the

cable from the sensor body. Compressing the black square

ring does take force,

twisting does not.

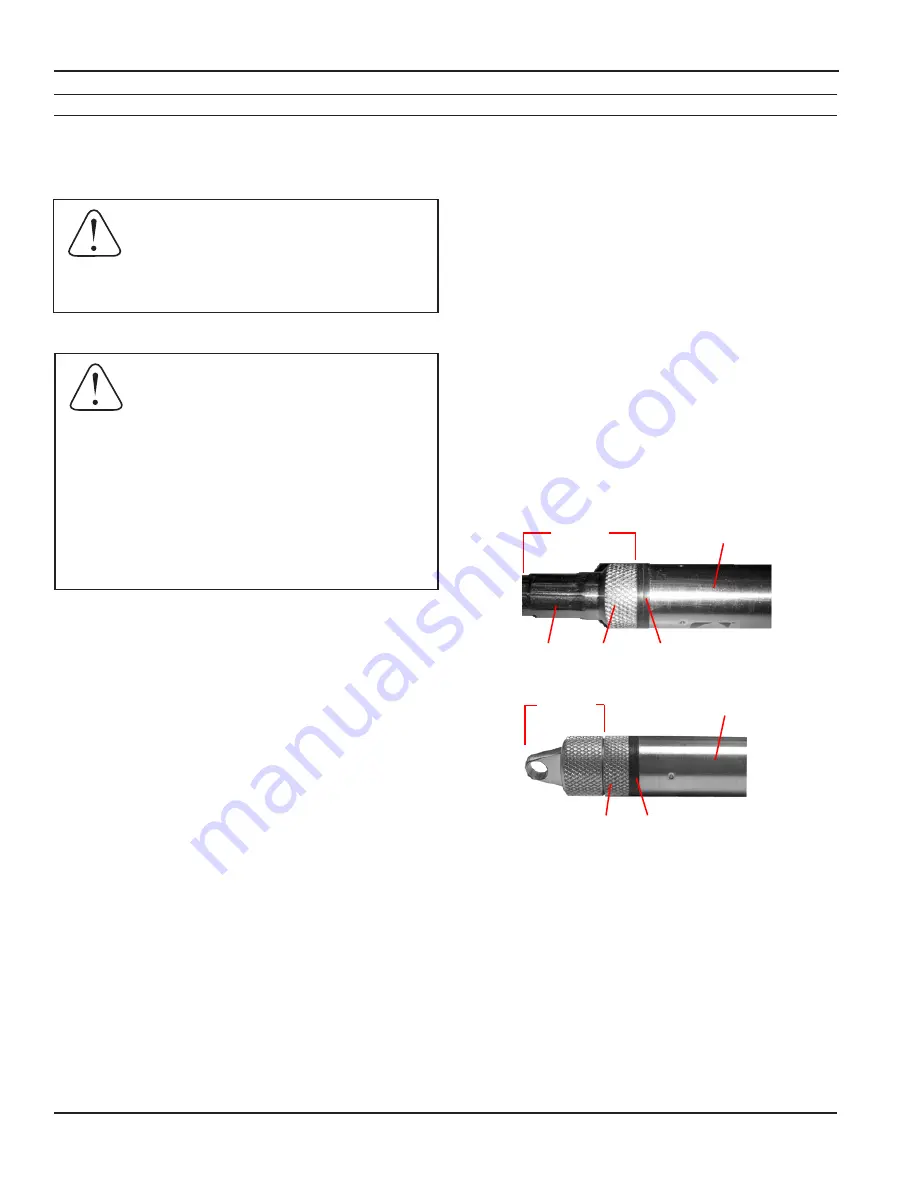

Cabled Sensor

Cableless Sensor

Care must be taken to compress the black square ring

before attempting to twist the housing.

Forceful twisting

of the housing can permanently damage the sensor

.

Securing the Sensor

In order to compress the black square ring, the sensor

must be secured so that you can apply downward pressure

to compress the ring. This can be done by holding in your

hand, using a vise, or using pliers, as follows.

Swage Knurling Black square ring

Housing

Top cap

Knurling Black square ring

Housing

Top cap

Battery Type:

Two 1.5V AA batteries—Lithium or Alkaline

(lithium recommended)

IMPORTANT!

Because changing the batteries involves

opening the water-tight seal, this must be

done in a clean, dry environment to avoid

contamination or moisture damage to the

circuitry.

IF USING ALKALINE BATTERIES

—PREVENT BATTERY LEAKAGE!

CT2X sensors are typically shipped with

lithium batteries. If, however, you are using

alkaline batteries, be aware that under some

circumstances alkaline batteries can leak,

causing damage to the sensor. To prevent

leakage, the following is recommended.

(Does

not apply to lithium batteries.)

• Change the batteries at least every 12

months.

• If the sensor will not be deployed for 3

months or more, remove the batteries.

Changing Batteries