WT-SERIES INSTRUCTIONS

Seametrics • 253.872.0284

Page 5

seametrics.com

Installation

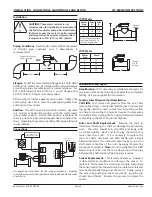

Piping Conditions.

Installing the meter with 10 diameters

of straight pipe upstream and 5 downstream is

recommended.

Flanges.

For WTS meters, standard flanges are 150 lb. ANSI

drilling. PVC meters can be installed with optional flanges

according to pipe manufacturer’s recommendations. For

PVC a bolt torque of 20-30 ft-lb for 3” and 4” flanges, and

35-50 ft-lb for 6” flanges is recommended.

Either partial or full-face gaskets can be used. Tighten the

bolts evenly. Use care to prevent a misaligned gasket from

entering the flow stream.

Position.

The WT-Series are all-position meters, operable

in a vertical or horizontal position, with the meter insert

in any radial position. A horizontal position is preferred if

there is a risk of air becoming trapped due to constant low

flows. Operating the meter in partially-filled pipe will result

in inaccuracies.

Connections

For operating instructions for the various electronic modules,

consult the manual for the specific module, included with the meter

at purchase.

CAUTION:

These water meters are not

recommended for installation downstream of

the boiler feedwater pump where installation

fault may expose the meter to boiler pressure

and temperature. Maximum recommended

temperature is 120˚ (PVC) or 200˚ (Metal).

10X Dia.

5X Dia.

Straight coupling can

be part of length

FLOW

WTP

Loop Power Supply

24-36 Vdc (dep on device)

To Other

Control

4-20 mA De

vice

Red

White

Black

Powe

r

Sensor

Puls

e

Output

Sensor Output

Black

Black

Red

INSTALLATION, CONNECTIONS, MAINTENANCE AND REPAIR

WTP Meter

WTS Meter

Maintenance and Repair

Recalibration.

If it is necessary to recalibrate the meter for

any reason, this can be done by any Seametrics-authorized

facility. Call your supplier for information.

Turbine Insert Removal and Installation.

CAUTION:

First remove all pressure from the line.

Then

remove the screws or bolts that hold the insert in place and

tug gently until the insert comes free. A twisting motion

can help to loosen the O-ring seal. Reverse the procedure

to reinstall, after coating the O-ring with lubricant (plastic

compatible in the WTP).

Do not overtighten.

Rotor and Shaft Replacement.

Examine the rotor to

determine if bearings or shaft are damaged or excessively

worn. The rotor should spin smoothly and freely, with

no visible wobble. Back and forth play should be very

minor, less than 1/64”. If it is necessary to replace the

rotor or shafts, first back out both shafts with a small

blade screwdriver. The rotor will come free as soon as the

shaft ends come free of the rotor bearings. Reverse the

procedure to reinstall.

Note:

Do not overtighten the shaft

screws.

Check to be sure that a small amount of free play

between the shaft ends and the bearings remains.

Sensor Replacement.

This is rarely necessary. However,

certain electrical conditions can damage the sensor. To

replace it, first remove the electronics module. Disconnect

the sensor leads from the electronics module terminals and

remove the threaded plug over the sensor. Finally, remove

the sensor by pulling on the sensor leads. A gentle tug

should be sufficient. Reverse the process to replace the

sensor.

Meter

Size

Dim

A

Dim

B

3”

12”

6.5”

4”

14”

7.0”

6”

18”

8.5”

NOTE: Flange options face-

to-face dimension (“A”) is

the same as plain ends.

A

Optional

Flanges

B

Optional

Flanges

Meter

Size

Dim A

3”

12”

4”

14”

6”

18”

8”

20”

A

Flange

150 lb

drilling

Summary of Contents for WTP-400

Page 2: ......