ADDITIONAL INSTALLATION

MATERIALS

SEARS Sump/Utility Pump Hose Kit, Stock No. 27909, con-

taining 24’ of 1-1/4” flexible plastic pipe, a 1-1/4” plastic

adapter and a stainless steel clamp.

Check Valve, SEARS Stock No. 2789.

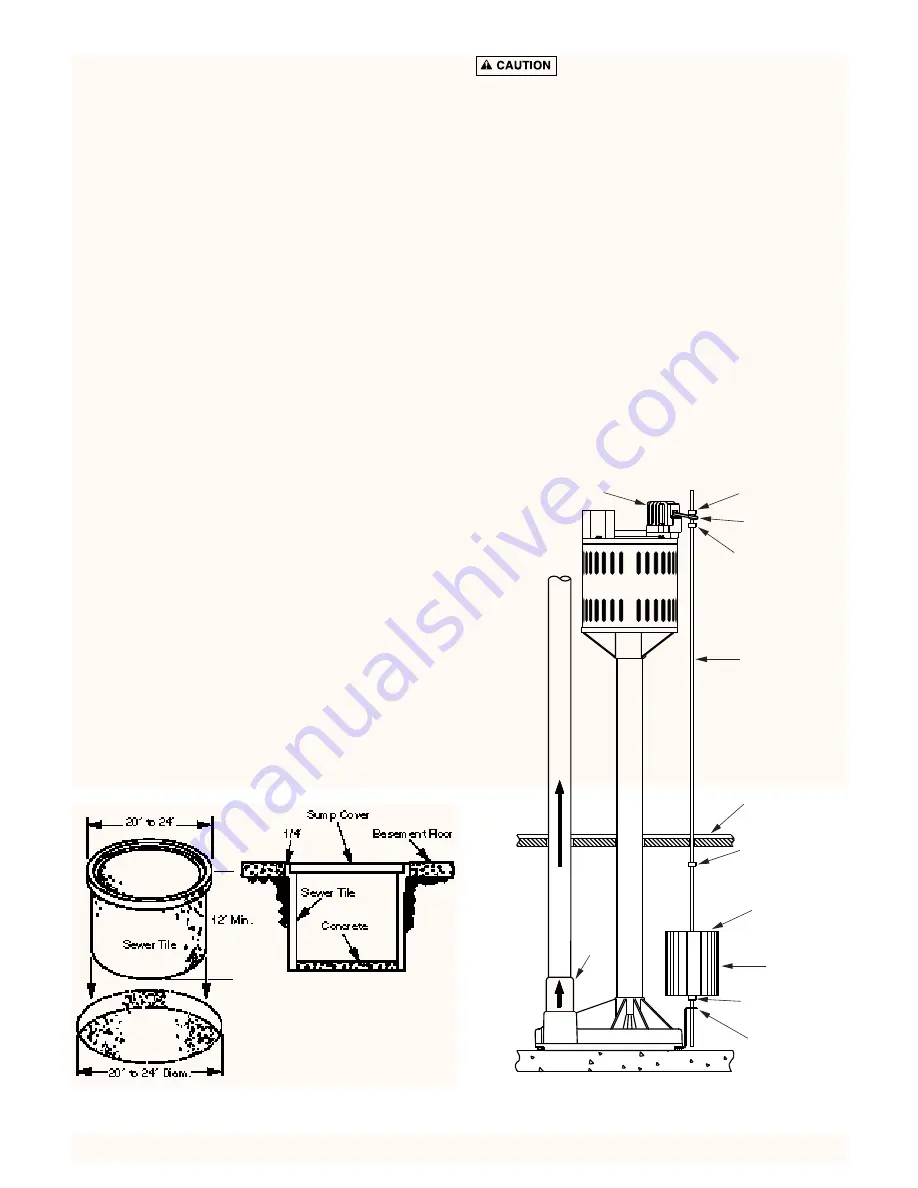

THE SUMP

The sump should be located at the lowest place in the base-

ment or area to be drained. Floor drains from other areas in

the basement may be tiled into the sump. Drain tile around

a house foundation can also be tiled into the sump, effec-

tively removing water and relieving pressure from this area.

A suitable sump can be a 20" or 24" sewer tile. Sump must

be at least 12” in diameter.

A sump cover is desirable to exclude refuse from the sump.

Consult local code for sump cover specifications.

SPECIFICATIONS

Power supply required ....................................115V, 60 HZ.

Horsepower (390.303300) ..............................................1/3

Horsepower (390.303490) ..............................................1/2

Motor duty .........................................................Intermittent

Liquid Temp. Range...........................32°F to 70°F(0°-21°C)

Circuit Requirement GFCI Class A..........................15 Amps

Motor full load (maximum - 390.303300) .............5.8 Amps

Motor full load (maximum - 390.303490) .............7.6 Amps

Discharge (390.303300) ......................................1-1/4" NPT

Discharge (390.303490) ......................................1-1/2" NPT

PUMP INSTALLATION

Check your local Electrical and Plumbing Codes before in-

stalling pump. You must comply with their rules.

Set the pump on the bottom of the sump, making sure that

it sits solidly and is level. Be sure there is enough space

around the pump to allow the switch free movement as the

sump water level changes. Do not install on clay, earth, or

sand.

Risk of flooding. If a flexible discharge

hose is used, pump may move around in sump when

motor starts

. If it moves far enough so that the switch hits

the side of the sump, the switch may stick and prevent

pump from starting. Make sure that pump is secured so that

it cannot walk around in sump.

Use 1-1/4” plastic pipe from installation kit No. 27909 for

the discharge pipe. Run the discharge pipe to the nearest

sewer outlet or other point of disposal. Use the most direct

route and the fewest turns and elbows possible. For Model

390.303490 use 1-1/2” x 1-1/4” reducer bushing (included

with pump).

Use Teflon tape to seal threads in plastic pipe. Hand tighten

only.

NOTE:

To avoid backflow into sump when pump shuts off,

install a SEARS Check Valve, Stock No. 2789, in threaded dis-

charge port of pump (390.303300) or 1-1/2”x1-1/4” reducer

bushing (390.303490). Reducer bushing is included with

Model 390.303490. Be sure arrow on check valve body

points away from the pump. This SEARS Check Valve is

equipped with an air bleed hole to prevent airlocking pump.

If using any other check valve, drill 1/8” (3.2 mm) hole in

discharge pipe just above pump body but below check valve

to prevent air locks.

3

Figure 1

Figure 2

Switch

Rubber Bushing

Stop (D)

Switch Arm

Rubber Bushing

Stop (C)

Stainless

Steel Rod

Sump Cover

Rubber Bushing

Stop (A)

Marked “TOP”

Float

Rubber Bushing

Stop (B)

Rod Guide

Check

Valve

1220 0894