4

MAJOR COMPONENTS AND

WHAT THEY DO

Impeller and Jet

Impeller turns with motor shaft, causing water to fly

out from its rim by centrifugal force. Impeller rotation

creates a vacuum which pulls in more water. Part of the

water is diverted back to the jet where it passes

through the nozzle and venturi. This creates more vac-

uum to draw in more water.

In shallow wells (less than 20 feet deep), the vacuum

created at the pump is enough to pull water to the

pump. Therefore, for shallow well use the jet is built

into the pump.

Pre-Charged Tank

The tank serves two functions. It provides a reservoir

of water under pressure and maintains a cushion of air

pressure to prevent pipe hammering and possible dam-

age to plumbing components. When water is drawn off

through the house fixtures, the pressure in the tank is

lowered and the pump starts.

Pressure Switch

The pressure switch provides for automatic operation.

Pump starts when pressure drops to 30 pounds and

stops when pressure reaches 50 pounds.

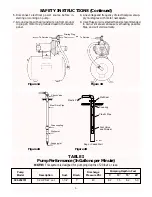

Check Valve or Foot Valve

This pump is equipped with a built-in check valve.

Install a check valve

as close to well as possible

on

well point installations. A foot valve must be installed

in the well

on dug or cased wells. See Figures 2A and

2B. For long horizontal pipe runs, install check valve as

close to well as possible (all types of wells).

INSTALLATION

Piping in the Well

The Sears 1/2 HP Shallow Well Water System can be in-

stalled on a dug well, drilled well or with a driven

point. In a dug or cased well, a foot valve and strainer

should be installed for easy priming. It should be in-

stalled five to ten feet below the lowest level to which

the water will drop while the pump is operating

(pumping water level). To keep sediment from clog-

ging the strainer, be sure it is five to ten feet above the

bottom of the well. Before installing the foot valve,

make sure that it works freely.

When using a foot valve, a priming tee and plug as

shown in Figure 1A, Page 3, are recommended.

When installed on a driven point well, your Shallow

Well Water System should have a check valve installed

as shown in Figure 2A, Page 3.

For a pump at sea level mounted directly over the well,

be sure the total lift from the pumping water level to

the pump does not exceed 20 feet. This will be less if

the pump is offset from the well.

The maximum lift of any pump decreases at the rate of

about 1’ less lift for every 1,000 feet of elevation above

sea level. For example, at Denver, Colorado (Elev.

5,000’) the pump loses five feet of lift. The maximum

depth from which it would pump water would there-

fore be 15 feet.

PUMP/TANK INSTALLATION

Pump

NOTICE:

Use Teflon tape supplied with the pump or

Plasto-Joint Stik

1

for making all pipe-thread connections

to the pump itself. To avoid stress-cracking, do not use

pipe joint compounds on the pump.

1

Lake Chemical Co., Chicago, Illinois

BASIC TOOLS AND MATERIALS NEEDED

Plastic Pipe Installation

Tools

Materials

Pipe Wrenches

Plastic Pipe and Fittings (as required to complete job).

Screwdriver

Knife or Saw to Cut Plastic Pipe

Teflon Tape (DO NOT use joint compound on plastic fittings).

Tire Pressure Gauge

Galvanized Steel Pipe Installation

Tools

Materials

Pipe Wrenches

Galvanized Pipe and Fittings (as required to complete job).

Screwdriver

Pipe Cutting and Threading Tools

Pipe Joint Compound or Teflon Tape

Tire Pressure Gauge