INSTALLATION

4

INSTALLATION

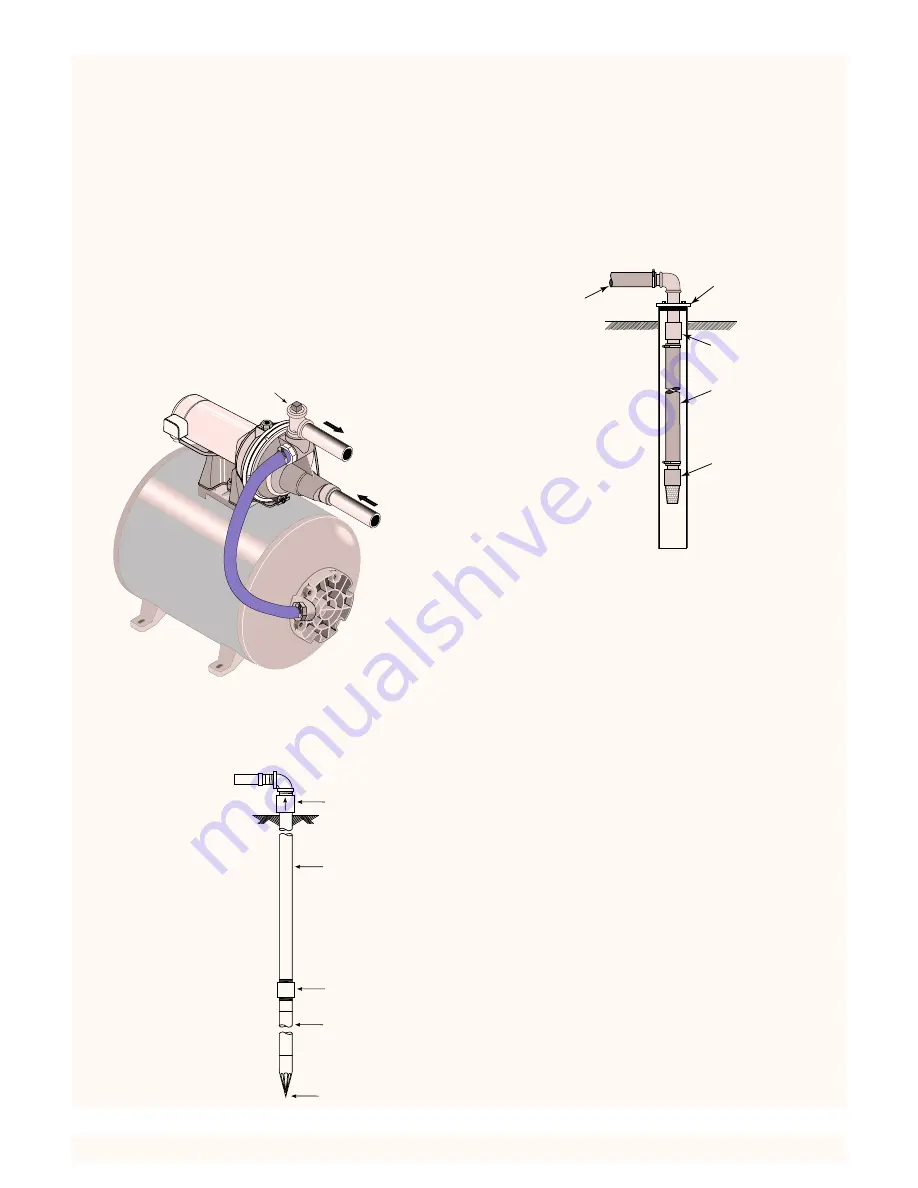

Piping in the Well

The Shallow Well Water System can be installed on a dug

well, drilled well or with a driven point. In a dug or cased

well, a foot valve and strainer should be installed for easy

priming. It should be installed five to ten feet below the low-

est level to which the water will drop while the pump is op-

erating (pumping water level). To keep sediment from

clogging the strainer, be sure it is five to ten feet above the

bottom of the well. Before installing the foot valve, make

sure that it works freely.

When using a foot valve, a priming tee and plug as shown in

Figure 1, are recommended.

When installed on a driven point well, your Shallow Well

Water System should have a check valve installed as shown

in Figure 2A.

For a pump at sea level mounted directly over the well, be

sure the total lift from the pumping water level to the pump

does not exceed 20 feet. This will be less if the pump is off-

set from the well.

The maximum lift of any pump decreases at the rate of about

1’ less lift for every 1,000 feet of elevation above sea level.

For example, at Denver, Colorado (Elev. 5,000’) the pump

loses five feet of lift. The maximum depth from which it

would pump water would therefore be 15 feet.

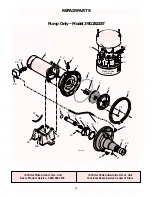

PUMP/TANK INSTALLATION

Pump

NOTICE:

Use Teflon tape supplied with the pump or Plasto-

Joint Stik

1

for making all pipe-thread connections to the

pump itself. To avoid stress-cracking, do not use pipe joint

compounds on the pump.

1. Wrap male pipe threads being attached to pump with

one or two layers of Teflon tape. Cover entire threaded

portion of pipe.

2. Do not overtighten threaded fittings in the plastic pump.

Be sure you do not try to tighten joint past thread stop

in pump port!

3. If leaks occur, remove fittings, clean off old tape, rewrap

with two to three layers of tape and remake the con-

nection. If joint still leaks, replace the fittings (fittings

may be undersized).

4. Be sure to support all piping connected to the System.

1

Lake Chemical Co., Chicago, Illinois

Horizontal Piping from Well to Pump

When the pump is offset more than 25 feet from the well,

horizontal suction pipe size should be increased to reduce

friction losses. Never install a suction pipe that is smaller

than the suction tapping of the pump.

Check valve

Steel drive pipe

Drive coupling

Well point

Driven point

2894 0697

Priming Plug,

Priming Tee

(User Supplied)

To Service

From

Well

Plastic Pipe

Plastic Pipe

Foot Valve

and Strainer

Coupling

Well Seal

Dug or Cased Well

611 1293

Figure 1

Figure 2A

Figure 2B

Check Valve

Steel Drive Pipe

Drive coupling

Driven point

Well point

Summary of Contents for CRAFTSMAN 390.252157

Page 15: ...15...