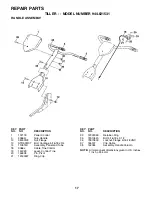

9

FIG. 9

3

2

1

5

4

6

7

CULTIVATING

Cultivating is destroying the weeds between rows to pre-

vent them from robbing nourishment and moisture from

the plants. At the same time, breaking up the upper layer

of soil crust will help retain moisture in the soil. Best

digging depth is 1" to 3".

• You will probably not need to use the depth stake.

Begin by tipping the depth stake forward until it is held

by the stake spring.

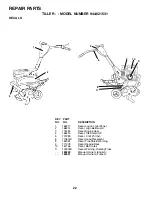

• Cultivate up and down the rows at a speed which will

allow tines to uproot weeds and leave the ground in

rough condition, promoting no further growth of weeds

and grass (See Fig. 10).

FIG. 10

BREAKING IN YOUR TILLER

Break-in your belt(s), pulleys and tine control before you

actually begin tilling.

•

Start engine, tip tines off ground by pressing handles

down and engage tine control to start tine rotation. Allow

tines to rotate for five minutes.

•

Check tine operation and adjust if necessary. See

“TINE OPERATION CHECK” in the Service and Adjust-

ments section of this manual.

TILLING HINTS

CAUTION: Until you are accustomed to

handling your tiller, start actual field use

with throttle in slow position.

To help tiller move forward, lift up the handles slightly (thus

lifting depth stake out of ground). To slow down the tiller,

press down on handles.

If you are straining or tiller is shaking, the wheels and depth

stake are not set properly in the soil being tilled. The proper

setting of the wheels and depth stake is through trial and error

and depends upon the soil condition. (The harder or wetter

the ground, the slower the engine and tine speed needed.

Under these poor conditions, at fast speed the tiller will run

and jump over the ground).

A properly adjusted tiller will dig with little effort from the

operator.

•

Tilling is digging into, turning over, and breaking up

packed soil before planting. Loose, unpacked soil helps

root growth. Best tilling depth is 4" to 6". A tiller will also

clear the soil of unwanted vegetation. The decomposi-

tion of this vegetable matter enriches the soil. Depend-

ing on the climate (rainfall and wind), it may be advisable

to till the soil at the end of the growing season to further

condition the soil.

•

Soil conditions are important for proper tilling. Tines will

not readily penetrate dry, hard soil which may contribute

to excessive bounce and difficult handling of your tiller.

Hard soil should be moistened before tilling; however,

extremely wet soil will “ball-up” or clump during tilling.

Wait until the soil is less wet in order to achieve the best

results. When tilling in the fall, remove vines and long

grass to prevent them from wrapping around the tine

shaft and slowing your tilling operation.

•

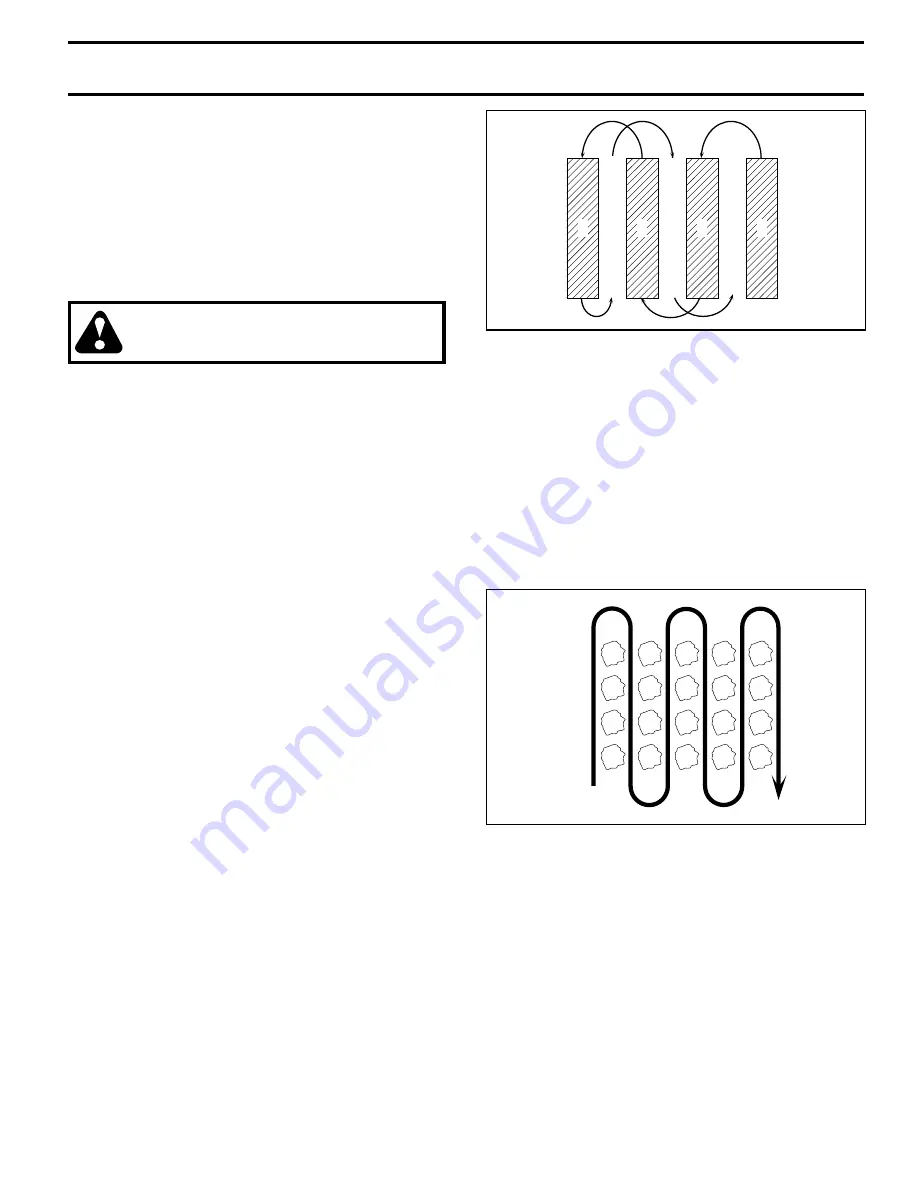

You will find tilling much easier if you leave a row untilled

between passes. Then go back between tilled rows.

(See Fig. 9) There are two reasons for doing this. First,

wide turns are much easier to negotiate than about-

faces. Second, the tiller won’t be pulling itself, and you,

toward the row next to it.

•

Set depth stake and wheel height for shallow tilling when

working extremely hard soil or sod. Then work across

the first cuts at normal depth.

OPERATION