16

ENGINE

Maintenance, repair, or replacement of the emission con-

trol devices and sys tems, which are being done at the

cus tom ers ex pense, may be performed by any non-road

engine repair es tab lish ment or in di vid u al. Warranty repairs

must be per formed by an authorized engine man u fac tur er's

service outlet.

SERVICE AND ADJUSTMENTS

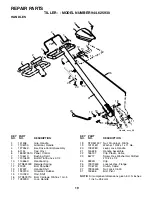

FIG. 28

CABLE CLIP

SCREW

DRIVE

CONTROL

CABLE

EXTENSION

SPRING

ENGINE

PULLEY

IDLER

PULLEY

TRANS MIS SION

PULLEY

LESS

TEN SION

5/8"

MORE

TEN SION

TO REPLACE GROUND DRIVE BELT

(See Figs. 23 and 28)

• Remove belt guard (See “TO REMOVE BELT GUARD”

in this section of this manual).

• Remove old belt by slipping off engine pulley fi rst then

remove from transmission pulley.

• Place new belt in groove of transmission pulley and

into engine pulley. BELT MUST BE IN GROOVE ON

TOP OF IDLER PULLEY. NOTE POSITION OF BELT

TO GUIDES.

• Check belt adjustment as described below.

• Replace belt guard.

• Reposition wheel and replace clevis pin and hairpin

clip.

• Replace inner and outer side shields.

GROUND DRIVE BELT ADJUSTMENT

(See Fig. 28)

For proper belt tension, the extension spring should

have about 5/8 inch stretch when drive control bar is in

“EN GAGED” position. This tension can be attained as

follows:

• Loosen cable clip screw securing the drive control

cable.

• Slide cable forward for less tension and rearward for

more tension until about 5/8 inch stretch is obtained

while the drive control bar is engaged.

• Tighten cable clip screw securely.

TO ADJUST CARBURETOR

The carburetor has been preset at the fac to ry and ad just ment

should not be nec es sary. However, engine per for mance

can be affected by dif fer enc es in fuel, tem per a ture, al ti tude

or load. If the carburetor does need ad just ment, contact

your nearest Sears or other qualifi ed service center.

IMPORTANT:

NEVER TAMPER WITH THE EN

GINE

GOVERNOR, WHICH IS FACTORY SET FOR PROP

ER

ENGINE SPEED. OVER SPEED ING THE ENGINE ABOVE THE

FACTORY HIGH SPEED SET TING CAN BE DANGEROUS. IF

YOU THINK THE EN GINE-GOVERNED HIGH SPEED NEEDS

AD JUST ING, CONTACT YOUR NEAREST SEARS OR OTHER

QUALIFIED SERVICE CENTER WHICH HAS THE PROPER

EQUIP MENT AND EX PE RI ENCE TO MAKE ANY NEC ES SARY

AD JUST MENTS.