1

of 12

DEM680E Series Delayed Egress

Magnalock

®

with EcoMag

™

Technology

Installation & Operating Instructions

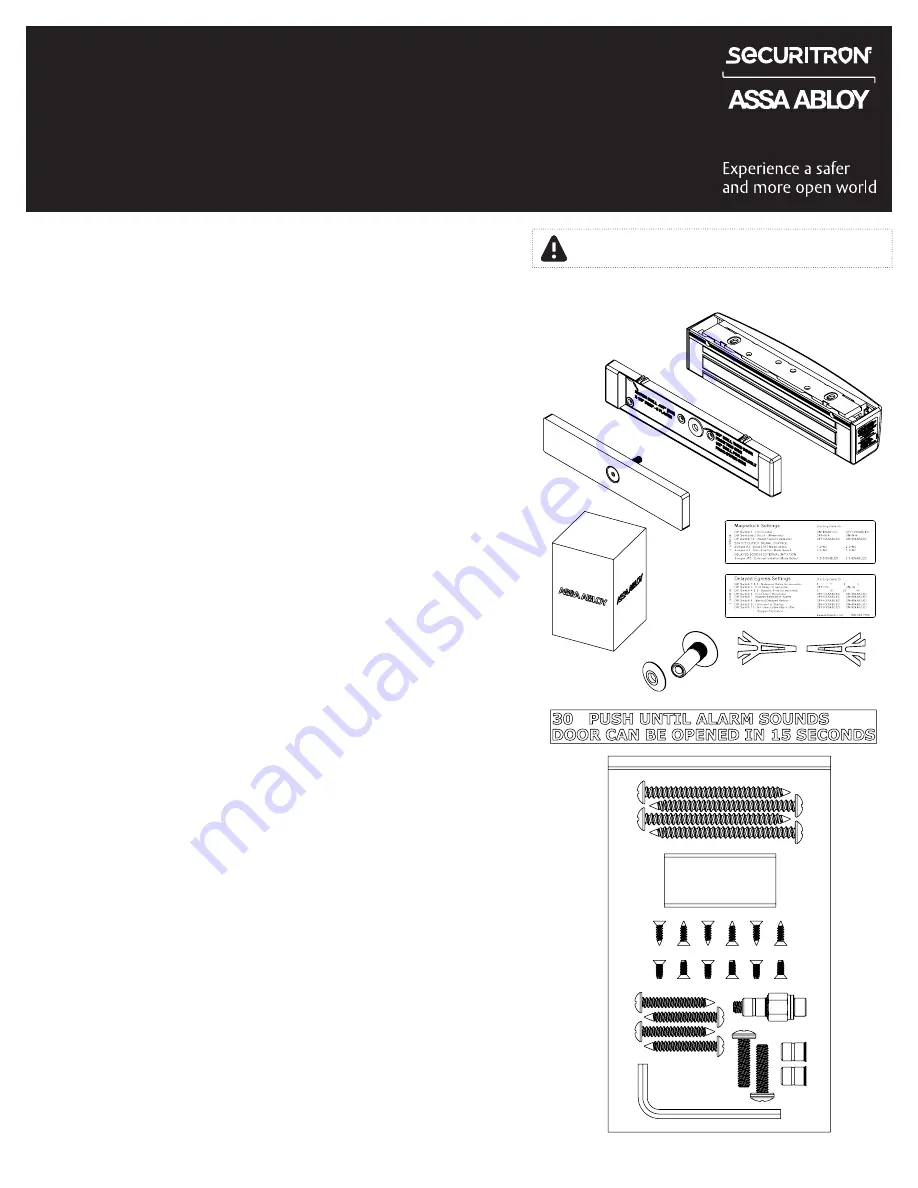

Product Components

A Magnalock & Mounting Bracket

B Strike Housing

C Strike Plate Assembly

D Wall Mounted Key Switch

E Settings Labels

F Sex Bolt & Tapered Washer

G Template Pins

H NFPA Door Label

Installation Hardware Pack Contents

I #14 X 3" Type A Phillips

Pan Head Screw (4)

J Threadlocker Packet

K WOOD DOORS: #6 X

1/2" Phillips Flat Head

Type A Steel Screw (6)

L METAL DOORS: 6-32 X

3/8" Phillips Flat Head

Type F Steel Screw (6)

M #12 X 1-1/2" Type A Phillips

Pan Head Screw (4)

N Rivet Nut Install Tool

O 1/4-20 X 1" Phillips Pan

Head Screw (2)

P 1/4-20 Rivet Nut (2)

Q 3/16" Hex Key

Diagram 1

Product Components

A

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

B

Specifications

Dimensions

•

Height: 2.50" [64 mm]

•

Depth: 2.56" [65 mm]

•

Length: 11.50" [292 mm]

Certifications

•

UL 10C Fire Rated, 1 Hour

•

CAN/ULC-S104 Fire Door Conformant

•

UL 294

•

UL Tested Ratings: Endurance:

100,000 cycles

•

ANSI/BHMA A156.23, Grade

2; E18501 Compliant

•

California State Fire Marshal Listed

•

NFPA 101

Electrical

•

Magnalock Minimum Current Draw

(±10%)

95 mA at 12 VDC

65 mA at 24 VDC

•

Magnalock Maximum Current Draw

(±10%)

575 mA at 12 VDC

315 mA at 24 VDC

Static Holding Force

•

1,200 lbs [544kg]

Operating Temperature

•

32˚ to 120˚F [0˚ to 49˚C]

•

Indoor use only

NOTE: Hardware is provided for various installations.

There will be leftover parts depending on the type of installation.

IMPORTANT: UL 294 compliance requires that the locking device be powered by a UL

294 (ALVY) or UL 603 (APHV) listed power supply and shall be installed in accordance

with the following UL and National Standards: NFPA 70 – National Electrical Code.

IMPORTANT

This Magnalock requires calibration upon installation.