5

of 12

4

of 12

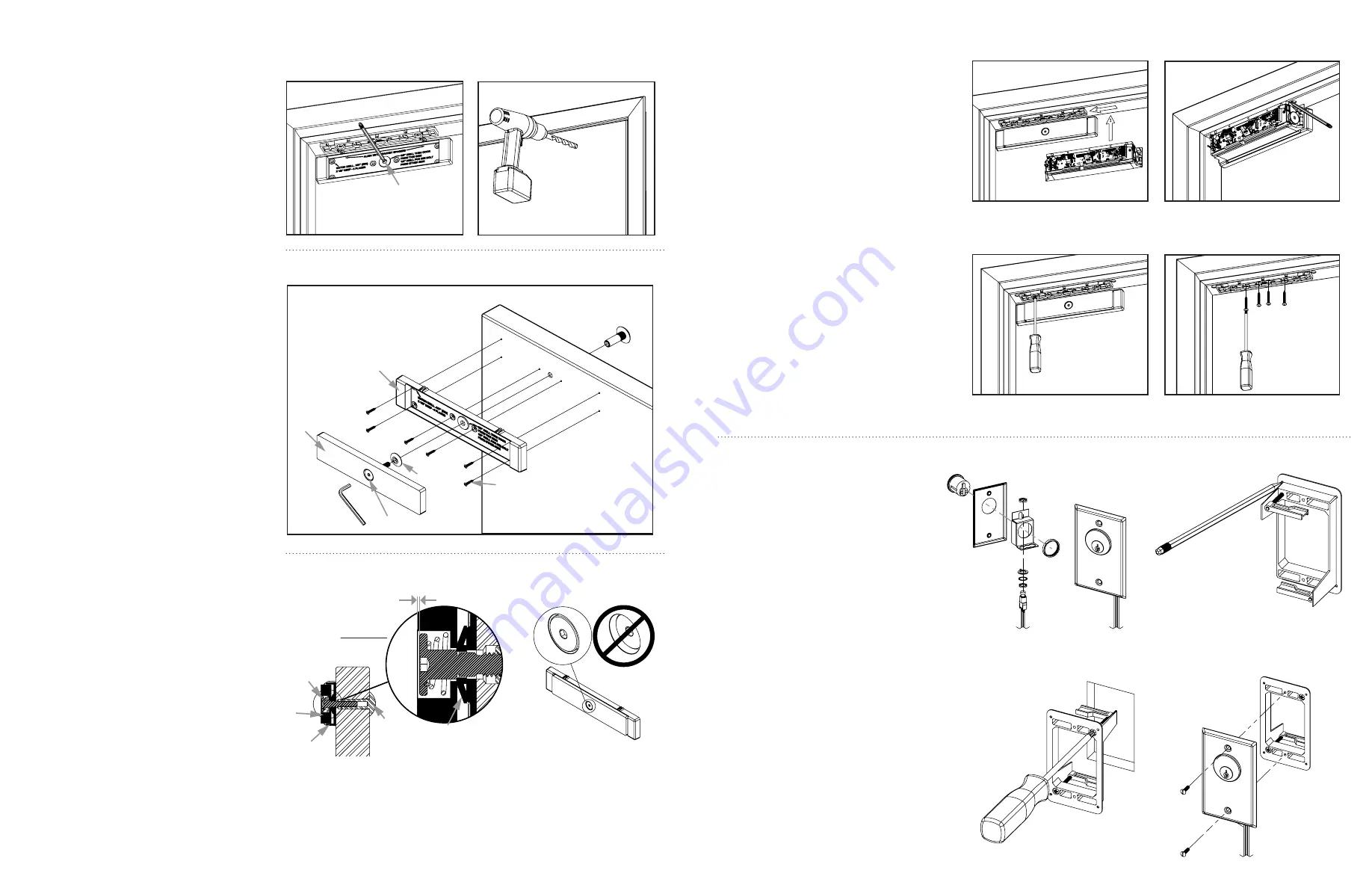

Diagram 11 Marking the

strike housing mounting hole

locations from the inside

Diagram 13 Securing the plate assembly to the door

Diagram 14 Strike assembly

installed – section view

Diagram 16 Mounting the

Magnalock to the bracket

Diagram 18 Tightening

the mounting screws

Diagram 20 Assembling

the key switch plate

Diagram 22 Installing

the mounting device

Diagram 15 Strike assembly

installed – inside door

Diagram 17 Marking the back

edge of the mounting bracket

Diagram 19 Installing the

final mounting screws

Diagram 21 Marking the wall cut-out

Diagram 23 Installing the key switch

Diagram 12 Drilling the sex

bolt hole from the outside

Installing the strike

on the door

1

With the door closed, ALIGN the strike housing

with the template pins as indicated on the

strike housing. Ensure the strike housing is

pushed up snug against the template pins.

2

MARK seven strike housing mounting

hole locations (see

Diagram 11

).

3

REMOVE the strike housing from the door and the

template pins from the lock mounting bracket.

From the INSIDE

4

DRILL a level 3/8" diameter hole for the

sex bolt all the way through the door at

the strike mounting center mark.

5

FOR A HOLLOW METAL DOOR:

DRILL six (6) #36

(0.107") holes through the inside skin of the door for

the strike housing mounting screws.

FOR A WOOD DOOR:

DRILL six (6) #36 (0.107)" x 1/2"

deep holes for the strike housing mounting screws.

From the OUTSIDE

6

FOR A HOLLOW METAL DOOR:

DRILL out the

3/8" diameter sex bolt hole to 1/2" diameter in the

outside skin of the door (see

Diagram 12

).

FOR A WOOD DOOR:

DRILL out the

3/8" diameter sex bolt hole to 1/2"

diameter completely through door.

Secure the strike plate

assembly to the door

7

INSERT the sex bolt into the hole from the

outside of the door (see

Diagram 13

).

8

ATTACH the strike plate housing using six (6) 6-32 x

3/8" Phillips flat-head screws for METAL

–OR–

six (6)

#6 x 1/2" Phillips flat-head screws for WOOD door.

9

CRITICAL STEP:

PLACE the tapered washer on the

strike assembly screw with the smaller diameter

surface of the washer facing against the back

of the strike plate, as shown in

Diagram 14

.

10

APPLY thread-lock compound (included)

to the strike assembly screw.

11

INSERT the strike assembly screw through the

strike housing and door and into the sex bolt.

12

CRITICAL STEP:

TIGHTEN the screw into the sex

bolt using the 3/16" hex wrench. While tightening,

gently tap the head of the sex bolt using a rubber

mallet until the head sits flush with the door.

NOTE:

To provide maximum door movement after

installation, the head of the strike assembly screw should be

approximately 0.025" (about the thickness of a paperclip)

below the surface of the strike as shown in

Diagram 15

.

NOTE:

DEM680E detects door movement through a concealed

‘patent pending’ strike assembly. OVERTIGHTENING the strike

assembly screw will reduce door movement range and may cause

false alarms. DO NOT OVERTIGHTEN the strike assembly screw.

Mounting the

Magnalock and aligning

to the strike plate

1

SLIDE the Magnalock assembly to fully engage

the lock chassis to the mounting bracket. Install

one of the three screws through one of the top

chassis holes and into the mounting bracket to

temporarily secure the Magnalock (see

Diagram 16

).

2

SLIDE the lock forward or backward so

that the entire face makes contact with

the strike plate on the closed door.

3

MARK the back edge of the mounting bracket

at each end and remove the Magnalock

from the bracket (see

Diagram 17

).

4

ENSURE that the mounting bracket

aligns with the marks and TIGHTEN the

mounting screws (see

Diagram 18

).

5

USING THE BRACKET AS A TEMPLATE, DRILL pilot

holes as necessary, then install and tighten the four

(4) final mounting screws (see

Diagram 19

).

FOR HOLLOW METAL DOORS

: DRILL 3/16" holes and

use #12 x 1-1/2" screws.

FOR WOOD DOORS:

DRILL 7/32"

holes and use #14 x 3" screws.

6

RETURN the Magnalock to the bracket and secure

the chassis to the bracket with three (3) screws.

Installing the

wall-mounted switch

1

ASSEMBLE the cylinder and switch to the wall-

mounted key switch plate (see

Diagram 20

).

2

MARK the corners for the mounting device

at the desired locations on the wall and

create a cut-out (see

Diagram 21

).

3

INSERT the mounting device into the cut-

out and fasten it in place with a Phillips

screwdriver (see

Diagram 22

).

4

MAKE the wire connections and install the

key switch plate using a flat-tip screwdriver

and two 6-32 screws (see

Diagram 23

).

Mark all seven (7) holes

Approximate .025"

Only hand tighten

strike assembly

screw

Strike

Assembly

Screw

Tapered Washer

Orientation

Strike

Plate

Sex Bolt

Strike

Housing

Metal Door: 6x 6-32 X 3/8" Self

Tapping Phillips Flat Head Screws

Wood Door: OOv #6 X 1/2" Type

A Phillips Flat Head Screws

STRIKE HOUSING

STRIKE PLATE

STRIKE ASSEMBLY SCREW

3/16" HEX KEY

TAPERED

WASHER

DOOR

SEX BOLT