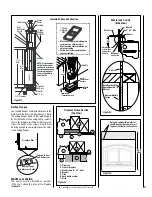

If this fireplace is being installed in a cold climate, it is especially important to seal all cracks

around the fireplace and wherever cold air could enter the room with noncombustible material.

Also, the outside air inlet duct should be wrapped with noncombustible insulation to minimize

the formation of condensation. Do not place insulation materials directly against the chimney

sections. We recommend that you use the insulated wall radiation shield since it will maintain the

home’s thermal barrier. AC chimney is NOT recommended in very cold climates (in areas with

temperatures below 32°F (0°C).

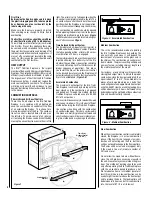

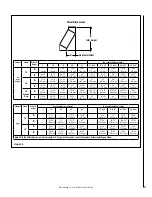

WARNING: THE HEARTH

EXTENSION IS TO BE

INSTALLED ONLY AS IL-

LUSTRATED.

Safety Metal Strip

Floor

Hearth Extension

Non-Combustible

Finish Material

(i.e. Tile or Marble)

Minimum 1”

Cement Board

Figure 9b

Non-Combustible Material

46-5/16”

16”

24”

45 Deg.

Area where

wood Mantel

can be

installed

4”

Figure 9a

(102mm)

(406mm)

56”

(1422mm)

Min.

(1176mm)

24”

(610mm)

(610mm)

Hearth

Extension

Mantel

u

Elevated fireplace installations

require a special “Z” Metal

Safety Strips (field provided),

in place of the safety metal strip

shown above. The safety strip

should extend the full width of

the fireplace. When more than

one safety strip is used they must

overlap by a minimum of 1”.

Platform

2”

Fireplace

Elevated Fireplaces

u

Fireplace

The crack between the fireplace

and the hearth extension must be

sealed with a non-combustible

material such as sand-cement

grout.

v

v

9

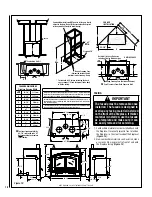

Facade Installation

Install the Facade per instructions provided in

Facade Kit (ordered separately - see

Page 21

).

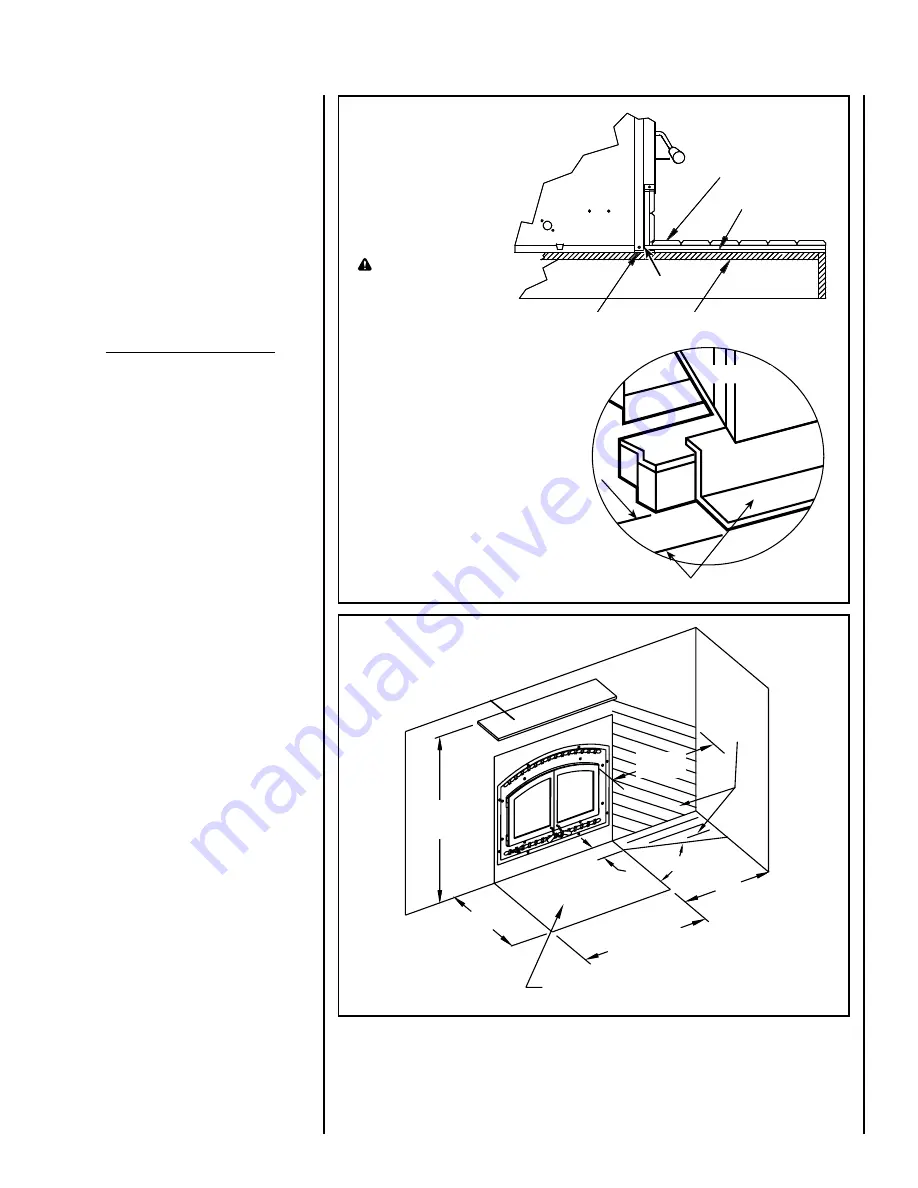

Framing, Facing And Mantel

The construction of the framing, facing, and

mantel must be in accordance with the stan-

dards and the following illustrations

(

Figures

10 and 11

)

:

A. Frame the fireplace using 2” x 3” or heavier

lumber.

B. WARNING: Combustible materials can-

not be used in the space directly above

the fireplace, except for the studs above

the facade that support the facing and

mantel. This area must remain empty

for a height of 80” (2,032 mm) mea-

sured from the base of the appliance.

C. Frame the fireplace with vertical studs at the

sides of the fireplace running from floor to

ceiling (see

Figure 10

).

If combustible facing

is to be used, position the studs back, from

the front edge of the fireplace (a space that

is the thickness of the facing material, so

that the facing can be installed flush with the

fireplace facing). Frame headers between

the vertical studs only as follows:

- Place 2” x 3” or 2” x 4” headers,

only along the upper part of the front,

side and back faces (some codes

may require a 2” x 6” on an outside

bearing wall). Do not put wood or

any combustible material within the

area above the fireplace except on the

front facing.

- Place headers only as required to sup-

port the facing and mantel.

D. WARNING: The fireplace must not be in

contact with any insulation or loose fill-

ing material. Cover the insulation with

Drywall panels around the fireplace.

Hearth Extension Requirements

The BIS™ Tradition fireplace may be installed

directly on a combustible floor. The supplied

safety metal strip must be positioned as follows:

One half under the front of the fireplace and the

other half must extend on the floor over which

the hearth extension will be built (see

Figure 9a

).

* The safety metal strip must cover the entire

width of the fireplace

The combustible floor in front of the fireplace

must be covered with a non-combustible mate-

rial (tile, marble, stone, etc). See

Figure 9b

.

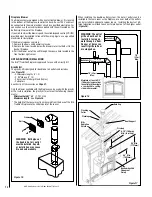

COLD CLIMATE INSTALLATIONS

Climates where temperatures will fall below

32° F (0° C).

The heating performance of the appliance will

vary depending upon the level of insulation,

house design, how the appliance is operated,

etc.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Summary of Contents for BIS Tradition BISTRAD

Page 25: ...NOTES 25 ...