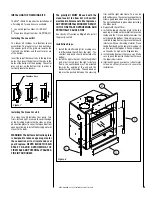

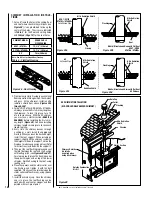

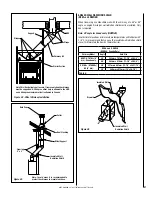

REFRACTORY REPLACEMENT

The intense heat of the fire will normally cause

hairline cracks in the refractory. These cracks

can be minimized by proper curing as described

in “First Fires”. They will not normally dimin-

ish the effectiveness of the refractory. If large

cracks develop, then the refractory should be

replaced. To replace the refractory bricks, fol-

low these steps:

1. Remove the front refractories

2. Remove the bottom refractory

3. Remove the left side refractory

4. Remove the right side refractory

5. Remove the back refractory

6. Remove the front ceramic baffle

7. Remove the rear ceramic baffle

To install the new refractories, follow the above

steps in reverse.

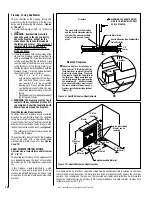

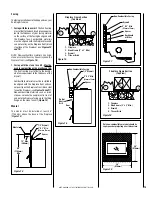

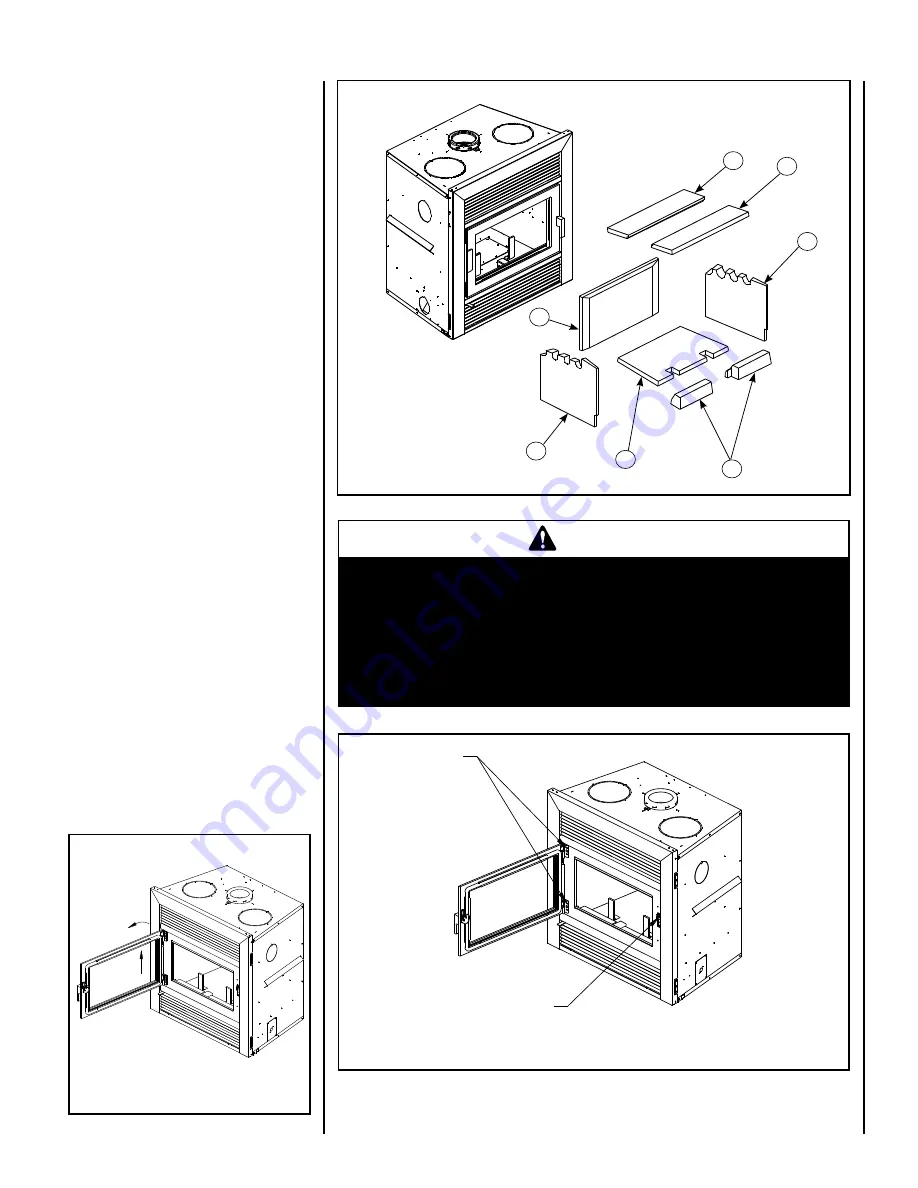

DOOR INSTALLATION

Your fireplaces door has been factory installed

and adjusted.

To remove the door simply unscrew the top

hinge from the door then lift the door (without

touching the trim over the door) to disengage

the male part of the bottom hinge from the

female part.

The door adjustment has been set at the factory.

If the fit is still not perfect, you can adjust the

door using the hinge screws.

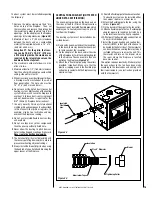

DOOR ADJUSTMENT

The door may need to be adjusted to be com-

pletely airtight. The gaskets’ air-tightness can be

adjusted using the adjustment screw located on

the right side of the fireplace facade (An Allen

key #1/8 – not supplied - will be necessary for

this adjustment).

Checking Door Seal -

A one-inch strip of paper

may be used to perform a test of the integrity

of the door seal. Close the door on the paper in

at least eight points. It is normal to feel only a

slight amount of friction. The door gasket does

not need to be “tight” in all areas, since a small

amount of leakage is not hazardous or detrimen-

tal to the performance of your fireplace.

Figure 4

Figure 3 - Door Installation

Figure 5

Hinges

Adjustment

Gasket Adjustment Screw

1

2

3

7

6

5

4

WARNINGS

•

Use only a Security Chimneys International Limited glass doors,

specifically designed for the BIS

®

Ultima CF fireplace.

•

The fireplace cannot be operated without door or firescreen. Consult

your dealer to select the correct replacement door or firescreen.

•

Important! To assure proper alignment of glass doors: Install this

fireplace in a square and plumb condition, using shims as neces-

sary at sides and/or bottom.

1. Front Refractories

2. Bottom Refractory

3. Left Side Refractory

4. Right Side Refractory

5. Back Refractory

6. Front Ceramic Baffle

7. Rear Ceramic Baffle

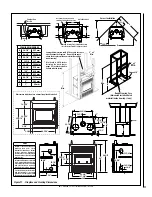

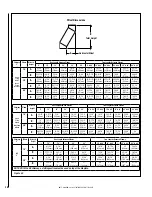

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

7