51

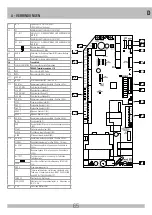

OPEN BUTTON (COM A+/OPEN)

The button controls the opening movement when the gate is stationary. If activated while

closing, it re-opens the gate.

B.I.O. BUTTON - OPENS WITH CLOCK FEATURE (COM A+/B.I.O.)

This function is useful during peak hours, when vehicle traffic is slow (e.g. entry/exit of

workers, emergencies in parking or residential areas and, temporarily, for moving operations).

By connecting a switch and/or a daily/weekly clock to COM A+/B.I.O., you can open and keep

the automation open for as long as the switch is pressed or the clock remains active. When

the gate is open, all the commands are ignored.

Releasing the switch or at the end of the set time, the automation closes immediately.

CLOSE BUTTON (COM A+/CLOSE)

Controls the closing movement when the gate is stationary.

TRANSMITTER

DIP 6 ON =>

It cyclically performs the commands open-stop-close-stop-open etc.

DIP 6 OFF =>

Opens the gate when closed. There is no effect if activated while opening. If

activated when gate is open, the gate closes. If activated while closing, the

gate reopens.

PEDESTRIAN OPEN BUTTON (COM A+/PED.)

Partial opening and closing control.

During pedestrian opening, pausing or closing, you can control the opening of any command

linked to the B2 board.

With DIP 6 you can choose the operation mode of the pedestrian push button.

DIP 6 ON =>

It cyclically performs the commands open-stop-close-stop-open etc.

DIP 6 OFF =>

Opens the gate when closed. There is no effect if activated while opening. If

activated when gate is open, the gate closes. If activated while closing, the

gate reopens.

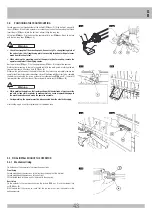

ELECTRIC LOCK (COM A+/LOCK-)

Set DIP 8 to ON to enable control of the electric lock when opening.

PULSE TO RELEASE THE ELECTRIC LOCK IN OPENING

Set DIP 9 to ON to enable the electric lock pulse release when opening (provided DIP 8 is ON).

If a command to open the gate is given when the gate is closed, the closing movement is

performed for 0.5 seconds and the electric lock is simultaneously activated (followed by a

0.5 second pause and then the opening of the gate).

MOTORS MANUAL RELEASE FACILITATION

Set DIP 10 to ON to enable easy manual release. As gate is closed a reverse motion with a

fixed time of 0.2 seconds occurs to facilitate the motor manual release.

PULSE TO ENGAGE THE ELECTRIC LOCK IN CLOSURE

Set DIP 11 to ON to enable the pulse engagement of the electric lock when closing. Upon

closing, motors are activated for 1 second at full voltage to ensure lock engagement.

OPERATION OF SAFETY ACCESSORIES

PHOTOCELLS (COM A+/PHOT 1, COM A+/PHOT 2)

NOTE: the transit through the photocells is signaled by a buzzer tone

DIP 4 OFF =>

if an obstacle is placed in range of the photocells when the gate is closed,

the gate does not open. During operation, photocells work when opening

(by starting the opening movement only after the obstacle is removed) and

closing (by starting the reverse movement only after the obstacle is removed).

DIP 4 ON =>

if an obstacle is placed in range of the photocells when the gate is closed

and the command to open is given, the gate opens (the photocells do not

work while opening). Photocells work only during closing (with reverse motion

restored after a second, even if they are still engaged).

ATTENTION: In case the receiver led remains lit, malfunctioning of the main supply

is suspected.

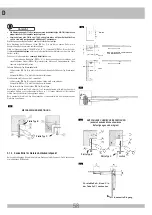

It is advisable to connect electrically to earth the

columns or the photocells stands to the terminal A -, to

shield the photocells from external noise.

Be careful not to short circuit the system when the

supply phases are inverted!

MONITORING OF PHOTOCELLS (A+ TEST A-)

Connect the photocell transmitter to A+ TEST/A- and set DIP 7 to ON.

The monitoring consists of a functional test of the photocell run before every movement.

The gate movement is therefore permitted only if the photocells have passed the functional

test.

CAUTION:

MONITORING OF THE PHOTOCELLS INPUTS (PHOTO 1/PHOTO 2) CAN BE

ACTIVATED WITH DIP 7 ON OR DEACTIVATED WITH DIP 7 OFF.

WARNING: If the AUTOTEST feature is enabled and only one photocell is connected,

a jumper must be made between the PHOT 1 and PHOT 2 terminals. If

the jumper is not made, the AUTOTEST fails and the gate will not move.

PHOTOCELL AUTOTEST ALARM (DIP 7 ON)

If the photocell fails the monitoring test, an alarm is displayed by the blinker lighting up

and gate movement is not allowed. Normal operation can be restored only by repairing the

photocell and pressing one of the controls.

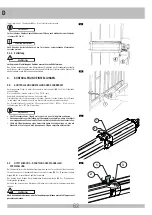

EDGES (SAFETY STRIPS) (COM A+/EDGE 1, COM A+/EDGE 2)

If engaged when closing, EDGE 1 reverses the motion in opening. If edge remains engaged,

it doesn’t permit the closing.

If engaged during opening, EDGE 2 reverses the motion in closing. If edge remains engaged,

it doesn’t permit the opening.

If edges are not used, jump the terminals COM A+/EDGE1/EDGE2.

EDGE ALARM

Flasher and buzzer are activated with 2 tones every 5 seconds for one minute.

STOP BUTTON (COM A+/STOP)

The STOP button stops the gate during any operation.

If held when the gate is fully open (or partially when using the pedestrian control) automatic

closing is temporarily deactivated (if activated by the TCA trimmer and LED DL11 on). It is

therefore necessary to use a new command to make it close.

The automatic closing function is reactivated on the next cycle (if activated by the TCA

trimmer and LED DL11 ON).

FUNCTIONING IN HOLD-TO-RUN MODE WHEN THE SAFETY DEVICES ARE FAILING

If one of the safety edges fails or remains engaged for more than 5 seconds, or if one of the

photocells fails or remain engaded for more than 60 seconds, the OPEN, CLOSE, START and

PED. commands will work only in hold-to-run mode.

The signal that this mode has been activated is given by the blinking of the programming

led DL1.

The radio commands and the automatic closing will be excluded, since their use in this mode

is not allowed by the norms.

Once the failing safety device is repaired, in automatic after 1 second, all standard commands

functioning again so radio commands and the automatic closing will be enabled again.

Note 1:

during this functioning in hold-to-run mode, in case of damage to the safety strips

(or photocells) the photocells (or safety strips) still work by interrupting the operation

in progress.

Note 2:

the stop command is not to be considered a safety command that can be bypassed

in this mode. Therefore, when pressed or damaged, it will not allow any movement

of the gate.

The hold-to-run mode is only an emergency operation which must be activated for a

very short period and with the complete installation at sight so to have a secure and

safe control of the system. As soon as possible however, the failing safety devices

must be repaired and activated.

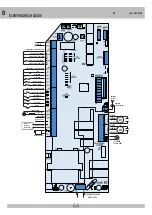

VISUAL AND SOUND ALARMS

BLINKER

Connect the flashing light to the blinker output. Use flashing lights ACG7059 and bulbs of

40W maximum.

PRE-BLINKING

DIP 5 - OFF => motor and blinker start simultaneously.

DIP 5 - ON => blinker starts 3 seconds before the motor.

BUZZER

It has the task to signal the intervention of the security, the anomalies and the memorization

and cancellation of the radio codes.

SIGNAL - 24Vdc GATE OPEN WARNING LIGHT (COM A+/SIGNAL-)

Signals when the gate is open, partially open or not closed completely. It turns off only when

the gate is completely closed.

During opening, it flashes slowly.

When the gate is stationary or opened, it is permanently on.

During closing, it flashes quickly

N.B.: Max 3 W. If warning lights are in excess, the control panel processes will be

G

B

24Vdc

Term.

A -

Summary of Contents for IDRO C 27/1B

Page 74: ...74 ...