12

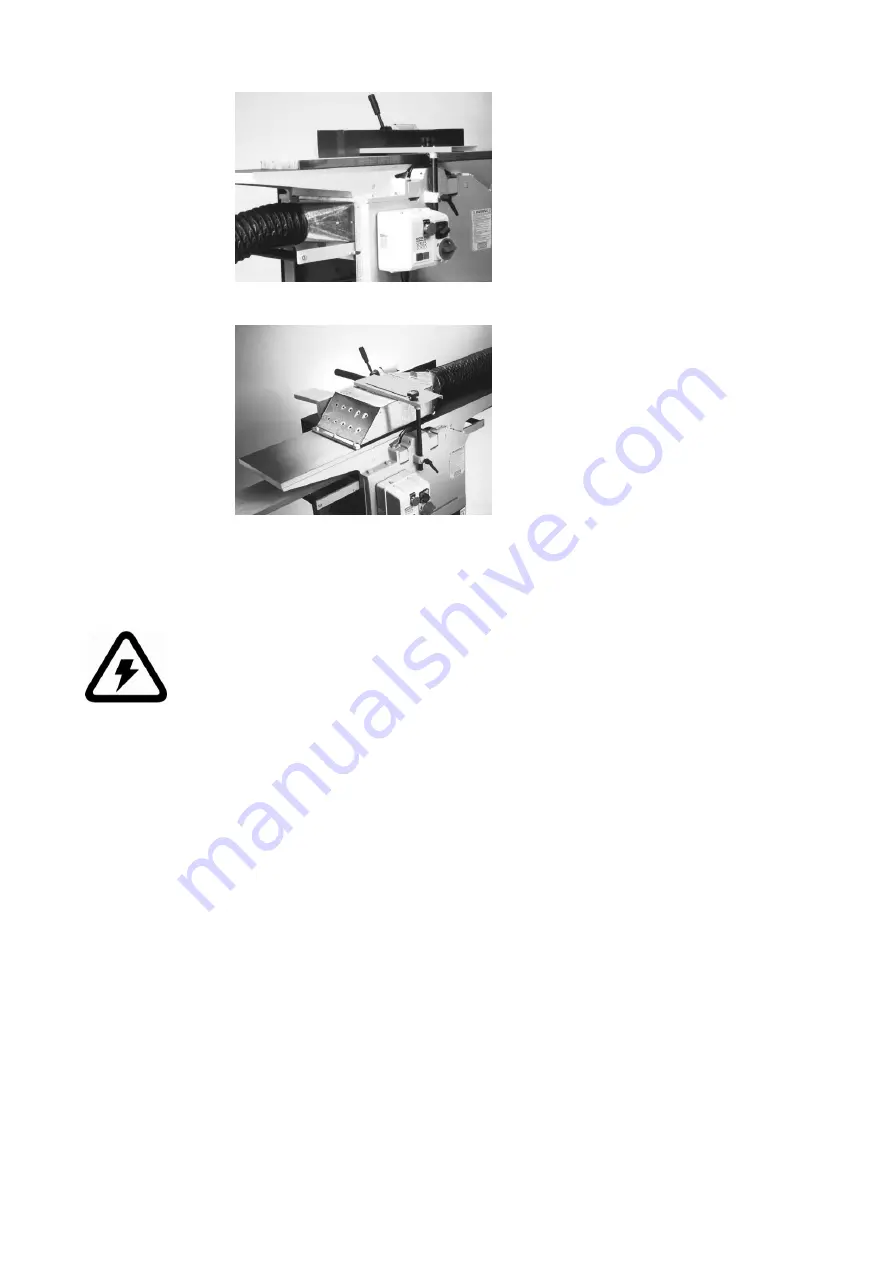

For Surfacing

The hood is designed to sit on the

thicknessing bed, and should be

inserted hollow side up, with the

exhaust outlet below the fixed outfeed

table. The lug on the underside of the

hood, attached to the exhaust outlet,

should locate against the end of the

thicknessing bed, with care being taken

that the anti-kickback fingers are not

fouled when the bed is wound up.

For Thicknessing

Position the fence to the rear of the

surfacing table. Place the hood

centrally over the cutterblock, hollow

side down, with the exhaust outlet

pointing toward the in-feed table rise

and fall handle. Bring the bridge guard

down over the hood and lock it in

position between the two welded

straps.

The diameter of the connection point is 125mm and reducers are not recommended

.

4.0 Electrical Installation

Electrical wiring should only be carried out by a fully qualified electrician

taking in account the following safety instructions.

Please follow these directions when connecting to the mains:

The motor and control gear have been wired in at the factory and tested before despatch. Do

not open the switch box on the machine without the written consent of the manufacturer.

Violating this stipulation could invalidate the machine’s warranty. All that is required is to

connect the power supply to the starter from your isolator.

First check that the supply details on the motor nameplate correspond with the site supply.

If the motor is operated on a voltage outside (plus or minus 6%) of the spot voltage, then

premature failure will occur.

Refer to the machine specification sheet at the front of the operator’s handbook to establish

the correct size of cable required. Undersize cable will lead to voltage drop at the motor

terminals.

Do not attempt to wire single-phase machines into a 13-amp plug socket.

Ensure that there is no voltage at the supply lead before connecting.

It is important to check rotation of the cutterblock, which should be clockwise when viewed

from the starter side of the machine. If necessary you can change the rotation by swapping

any two brown wires on the supply side.

Summary of Contents for PT255

Page 36: ...36 14 0 PT255 Planer Thicknesser Parts Diagram ...

Page 39: ...39 ...

Page 40: ...40 ...