18

9.0 Surface Planing

Caution: Ensure that all stock is clear of the blades before start-up.

When surfacing, the depth of cut is set by adjusting the height of the infeed table, using the

Surface Table Rise and Fall Handle. The outfeed table is already set level with the cutting circle

of the cutterblock. The sawn finish and the straightness of the timber determine the amount of

cut required.

For normal working it is good practice to set the amount of cut to 1.5mm.

When planing rough sawn or bowed timber the amount of cut can be increased to 3mm, so as to

obtain a clean finish with one pass over the cutters.

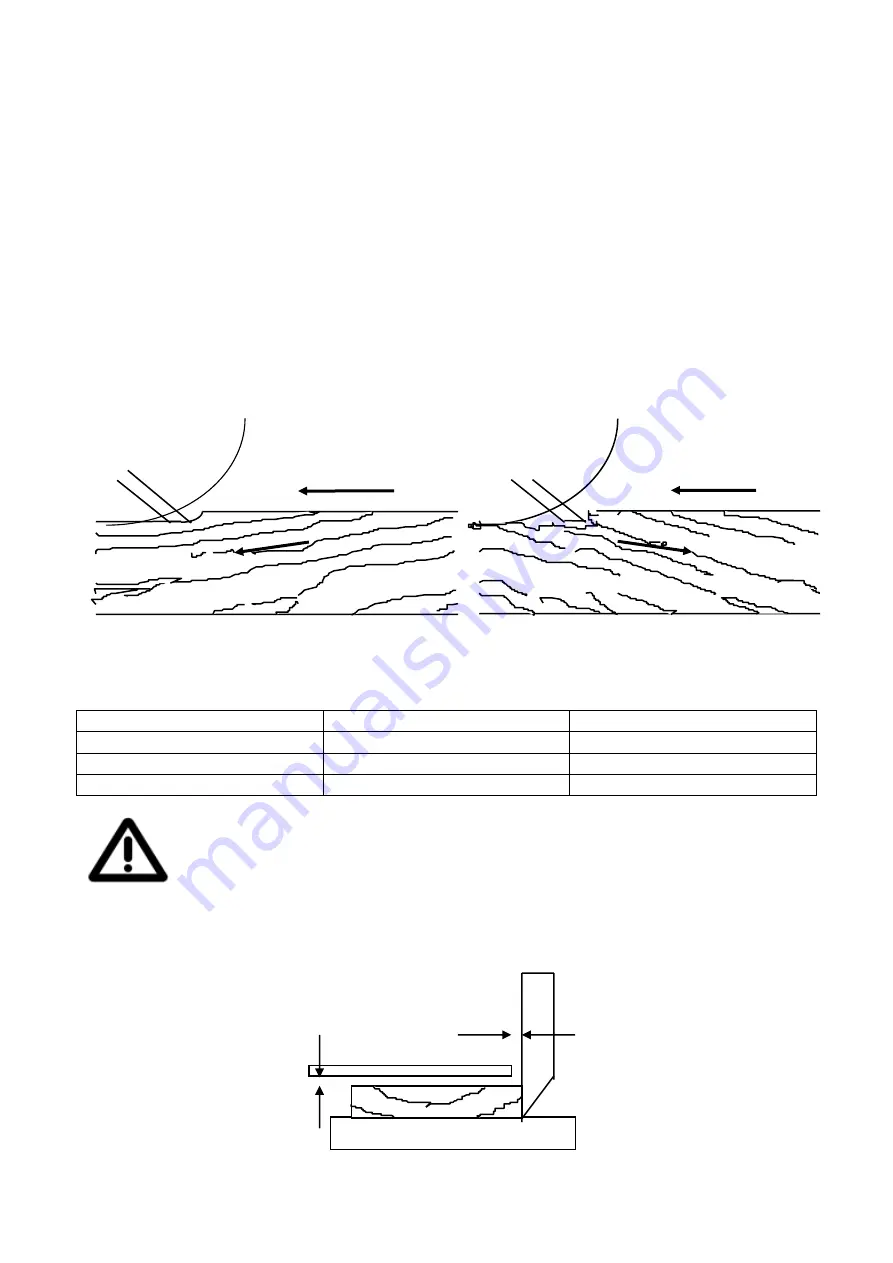

The timber should be fed in with consideration to the grain direction. The following illustration

shows how timber fed through the cutters against the grain will cause it to tear out, producing a

ragged finish.

Always feed with the grain running down towards the front of the table when

in the planing mode, and the opposite when thicknessing.

Correct

Incorrect

Feed

Feed

Slope of grain

Slope of grain

9.1 Flatting

Workpiece dimensions:

Length

< 250mm

Only work with a push stick

>1500mm

Extn rollers or 2

nd

person reqd

Width

Max 255mm

Thickness

Min 10mm

If a workpiece is smaller than 10mm it may split if the depth of cut is too large

(4mm). The finished planed workpiece must not be thinner than 6mm.

When flatting, the wood is passed below the bridge guard, which should be within 10mm of the

timber and 10mm of the fence, as shown below:

10mm

Bridge Guard

10mm

Summary of Contents for PT255

Page 36: ...36 14 0 PT255 Planer Thicknesser Parts Diagram ...

Page 39: ...39 ...

Page 40: ...40 ...