8

|

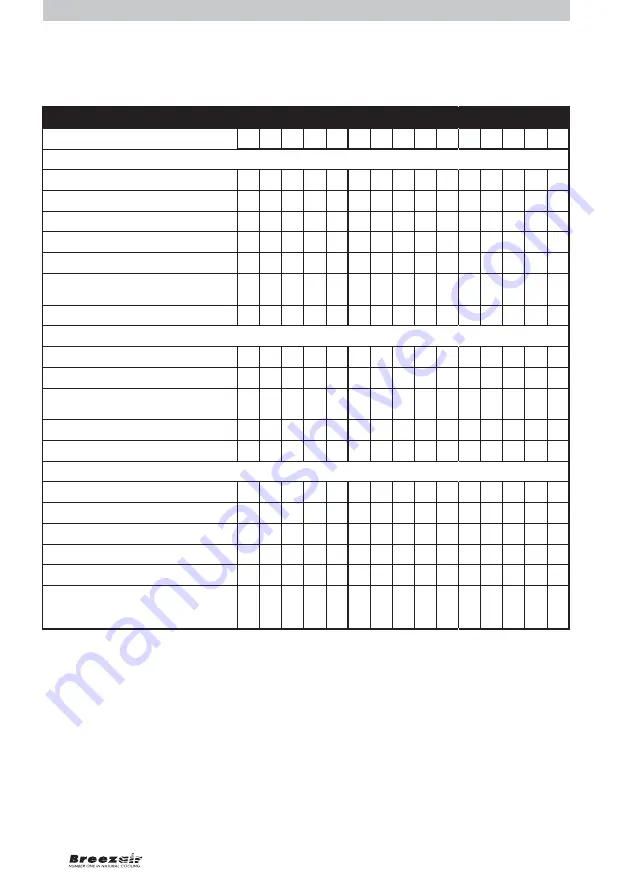

MAINTENANCE SCHEDULE SERVICE CHECKLIST

Service No.

Service Date Service Technician

Service Company

No.1

........................... ......................................

............................................

No.2

........................... ....................................... ............................................

No.3

............................ .......................................

............................................

No.4

............................ .......................................

............................................

No.5

............................ .......................................

............................................

Service Item

Check/Adjust

Clean

Replace

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

Water Distribution System

Chillcel Pads (replace as required)

Pad Retaining Washers/Pins

Tank/Water Reservoir

Pump Filter

Water Probes

System Washers, Seals and O’Rings

(replace as required)

Drain Valve/Bleed System Operation

Component Function

Pump Operation

Drain Valve Operation

Motor Operation (reset motor amps

where required)

Solenoid Operation

Wall Control Operation

General Operation

Water Level Set Point

Water Fill Time

Water Drain Time

Water Distribution across Pads

Airflow through system/Outlets

General Product condition (includes

correct fitting of all components and

items - replace as required)