CYLINDER HEAD, CYLINDER, PISTON

CYLINDER HEAD, CYLINDER, PISTON

3-5-31

JJ

F

F

E

E

D

D

G

G

H

H

A

A

B

B

C

C

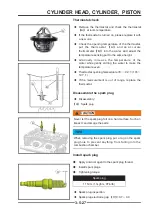

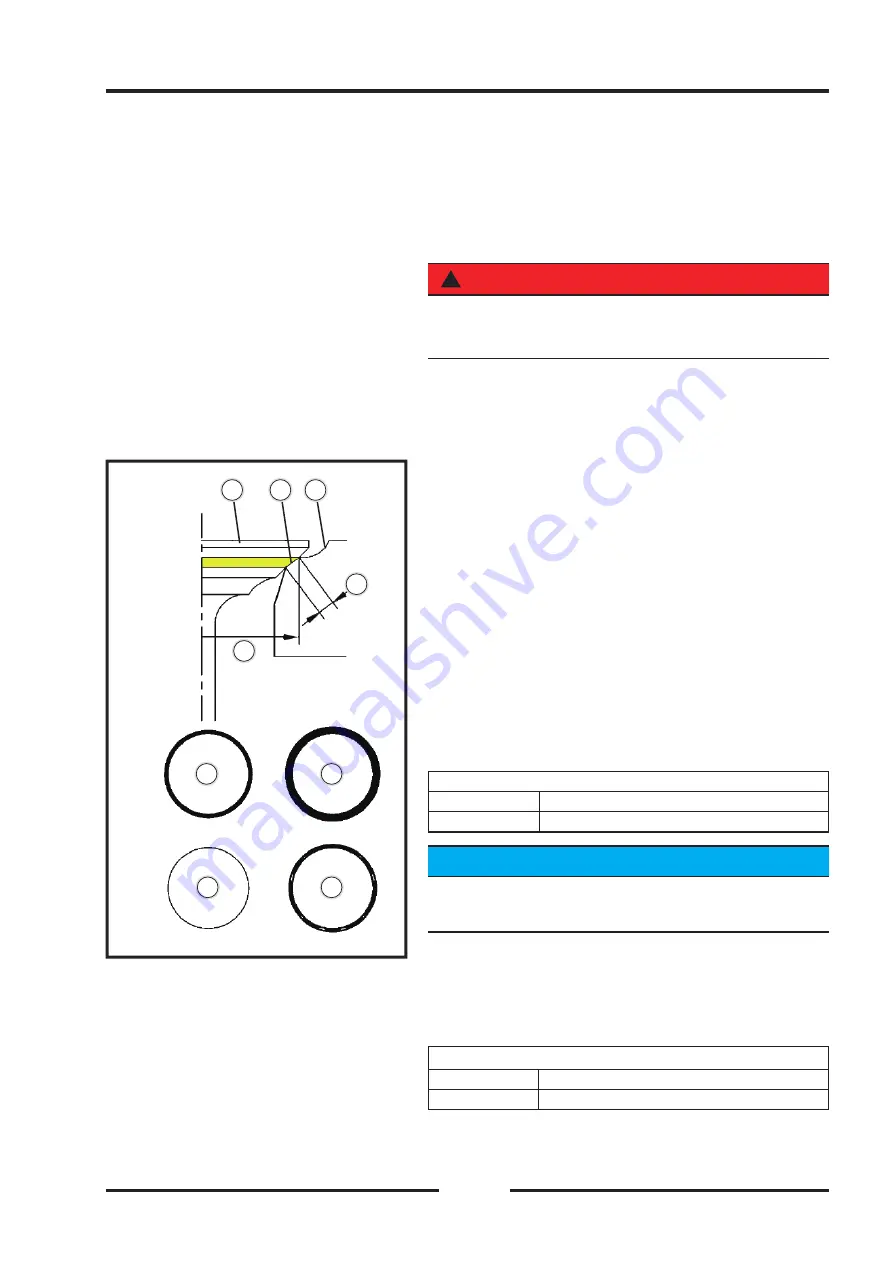

Seat ring repair

◆

S e a t r i n g r e p a i r s h o u l d b e c a r r i e d o u t b y

professionals who are proficient in cylinder head

repair technology. Repair techniques vary, so please

follow the valve repair equipment manufacturer's

instructions. Do not over-grind the seat ring.

!

WARNING

When disassembling and reassembling the cylinder

head, wear goggles or face shield.

Seat ring inspection

◆

Remove the valve.

◆

Check the contact surface

【

A

】

between the valve

【

B

】

and the seat ring

【

C

】

.

◆

Paint the seat ring.

◆

Push the valve into the valve guide.

◆

Use a grinding tool to press and rotate the valve

relative to the seat ring.

◆

Take out the valve and check the pattern of the

contact surface on the seat ring. The width of the

entire circle must be appropriate.

◆

Measure the diameter of the outer ring of the contact

surface on the seat ring

【

D

】

.

◆

If the outer diameter of the seat ring contact surface

is too large or too small, repair the seat ring (see

seat ring repair).

Outer diameter of seat ring contact surface

exhaust

31.8 ~ 31.9mm (1.2520" ~ 1.2559")

intake

36.8 ~ 36.9mm (1.4488" ~ 1.4528")

TIPS

The valve stem and valve guide must be good,

otherwise the check will be inaccurate.

◆

If the seat ring interface shape is not good, repair

the seat ring (see seat ring repair).

◆

Use a vernier caliper to measure the width of the

part without carbon deposits (bright part) on the seat

ring

【

E

】

.

Width of contact surface of seat ring

Exhaust

1.5 ~ 1.6mm (0.0591" ~ 0.0630")

intake

1.0 ~ 1.1mm (0.0394" ~ 0.0433")

If the width is too wide, too narrow or uneven, repair the

valve seat (see valve seat repair)

【

F

】

Good

【

G

】

Too wide

【

H

】

too narrow

【

J

】

Uneven

Summary of Contents for S301000-20100A

Page 1: ...SERVICE MANUAL SSV 4 3 4 130 6 54...

Page 50: ...ENGINE LUBRICATION SYSTEM 3 1 2 Exploded view...

Page 63: ...EFI SYSTEM 3 2 2 Exploded view Exploded view...

Page 67: ...STARTING SYSTEM 3 3 2 Exploded view...

Page 75: ...CRANKCASE CRANKSHAFT BALANCE SHAFT 3 4 2 Explosive view...

Page 76: ...CRANKCASE CRANKSHAFT BALANCE SHAFT 3 4 3 Explosive view of Up and down the case sub assembly...

Page 100: ...CYLINDER HEAD CYLINDER PISTON CYLINDER HEAD CYLINDER PISTON 3 5 3 Exploded view...

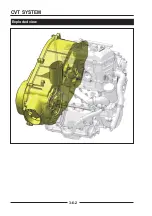

Page 141: ...CVT SYSTEM 3 6 2 Exploded view...

Page 151: ...WATER PUMP ASSEMBLY 3 7 2 Exploded view...

Page 197: ...6 6 COOLING SYSTEM SPECIAL TOOLS AND SEALANTS Silicone Sealant Special tools and sealants...

Page 227: ...9 2 FRONT REAR SUSPENSION EXPLODED VIEW OF FRONT SUSPENSION...

Page 229: ...9 4 FRONT REAR SUSPENSION EXPLODED VIEW OF REAR SUSPENSION...

Page 247: ...10 5 WHEELS AND TIRES SPECIAL TOOLS Jack...

Page 261: ...11 4 BRAKE SYSTEM SPECIAL TOOLS Inside Circlip Pliers...

Page 314: ...14 4 ELECTRICAL SYSTEM EXPLODED VIEW...

Page 407: ...14 97 ELECTRICAL SYSTEM ELECTRIC SCHEMATIC DIAGRAM...