3-10

PRE-RIDE INSPECTION

Perform a pre-ride inspection before each ride to detect any potentials problem

that could occur during operation. The pre-ride inspection will help you monitor

component wear and deterioration before they become a problem.

Correct any problems that you discover to reduce the risk of a breakdown or

accident.

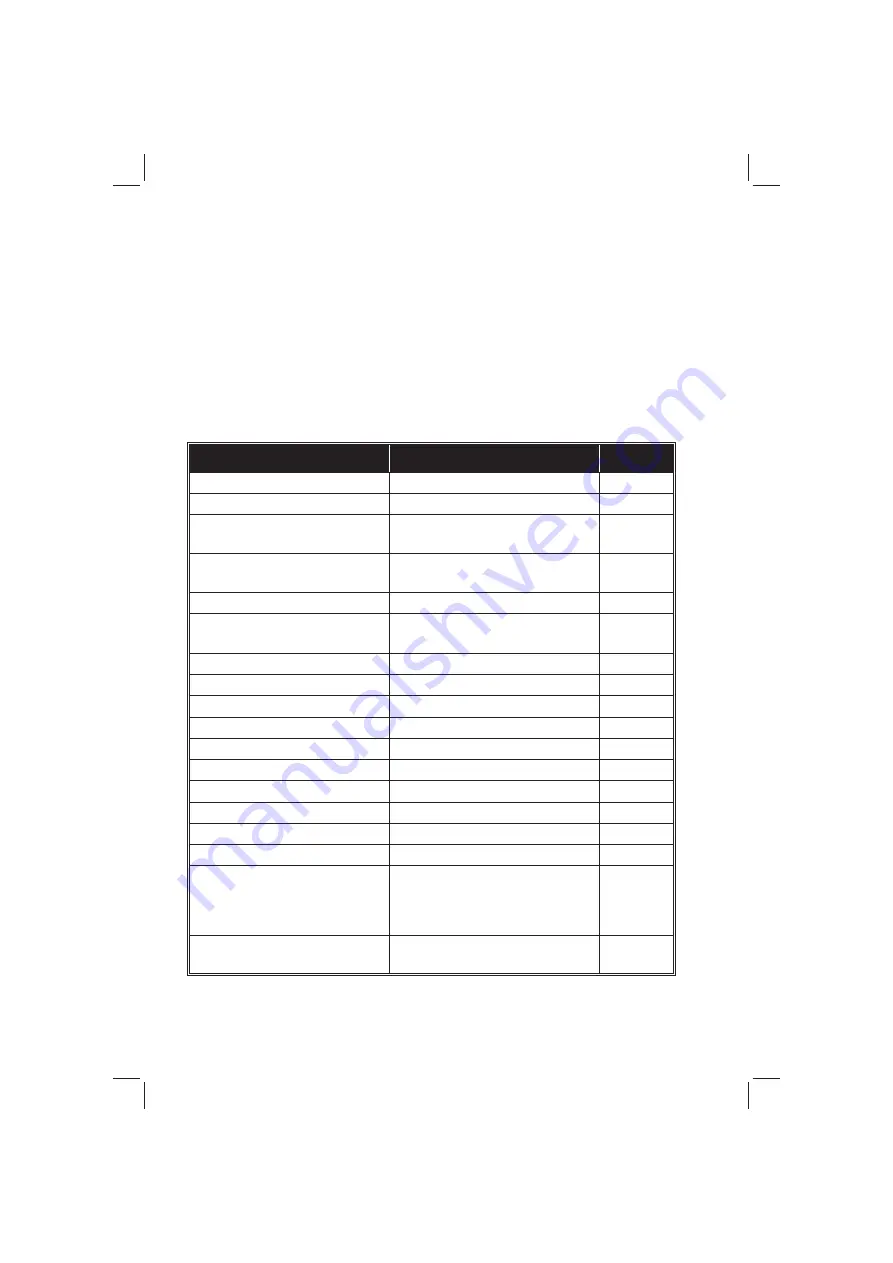

Inspection Items

Item

Note

Page

Brake system

Ensure proper operation

4-17

Brake fluid

Ensure appropriate level

4-18

Front suspension

Check and lubricate if

necessary

4-24

Rear suspension

Check and lubricate if

necessary

4-24

Tire

Check status and pressure

4-19

Wheel/fastener

Check to ensure the

tightness of fasteners

4-20

Nut

、

bolt

、

fastener

Check to make sure it's tight

——

Fuel

Ensure appropriate level

——

Engine oil

Ensure appropriate level

4-8

Coolant level

Ensure appropriate level

4-18

Coolant pipe

Check leakage

——

Throttle

Ensure proper operation

——

Indicator/switch

Ensure proper operation

2-3

Air intake prefilter

Check ,clean

4-25

Front headlight

Check operation

2-3

Brake light/taillight

Check operation

2-3

Seat belt

Check the length of the

seat belt for damage and

check whether the latch is in

normal operation

2-9

Cab door

Inspect doors and latches

for wear or damage

2-10

Summary of Contents for SGW1000F-S3

Page 1: ......

Page 2: ...3...

Page 10: ...1 3 1 2...

Page 11: ...1 4 3 4 5 6 7 8 9...

Page 12: ...1 5 10 11 12 13 14...

Page 61: ...MAINTENANCE MAINTENANCE...