Version Nr. 1-8 - 21.06.2022

Doc. No. 9943152081

15 / 17

15. Taking into operation

Attention! The unit can be damaged by lack of lubricant. To ensure that the compressor is adequately

lubricated the oil, which has been displaced during transport, must be allowed to flow back into it. The unit must

therefore be allowed to stand for at least 30 min. before being connected to the mains and taken into operation.

The unit / system must be protected with a MCB Type D or K.

Upon connection the internal fan will start working. If the temperature inside the enclosure is higher than the

set value of the controller both the compressor and external air fan start working. Once the air inside the

enclosure reaches the set temperature the compressor and external fan will stop.

The hysteresis is 3K, the minimum ON-time is 4 minutes, the minimum OFF-time is 3 minutes, for units with a

cooling capacity of more than 1 kW is it usually 7 minutes.

The unit is pre-set at 95°F, which is suitable for most of the electronic devices.

16. Trouble shooting

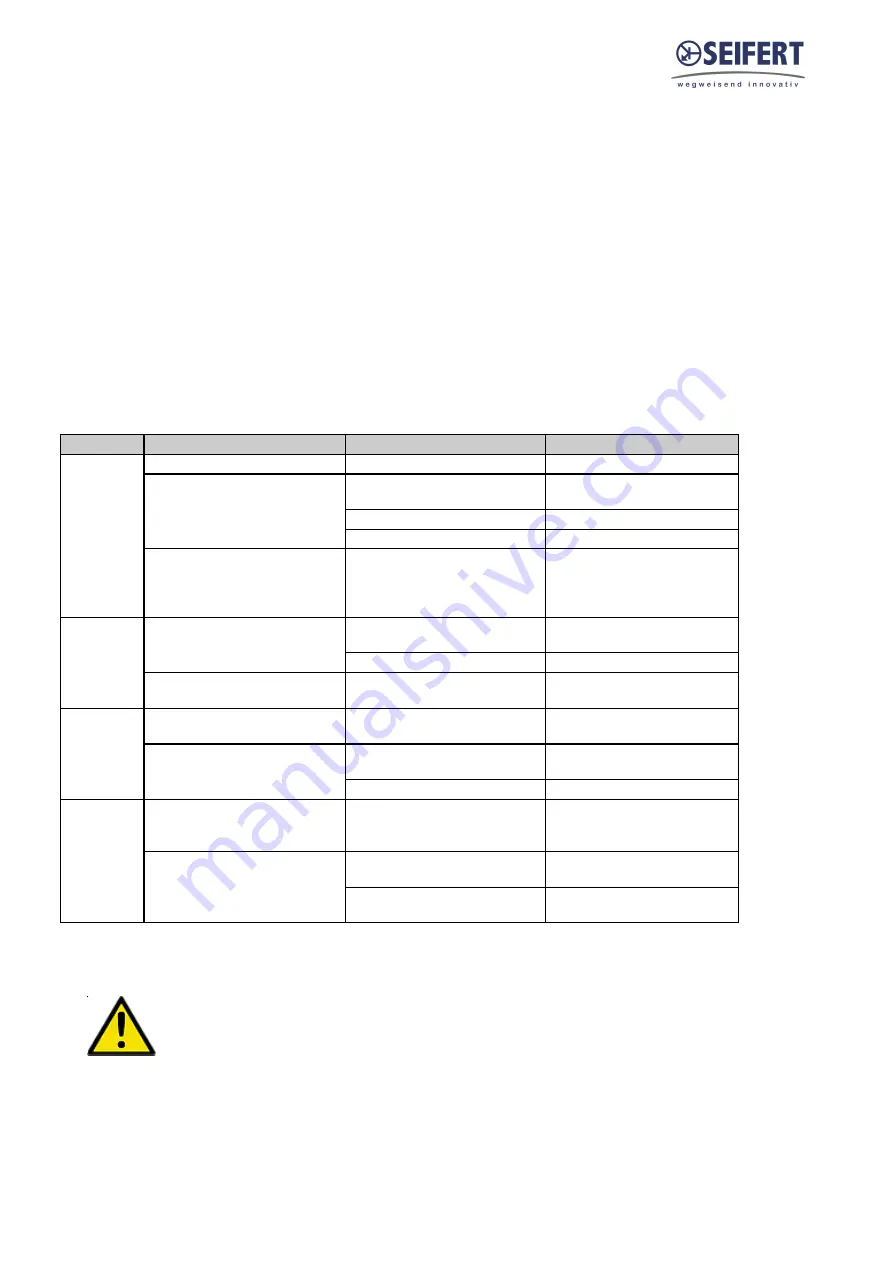

Failure

Condition

Cause

Solution

Unit

doesn't

cool

Internal fan does not work

Power not connected.

Verify power supply

Internal fan works, external fan

and compressor don't work

Enclosure temperature is below

setting temperature (St1)

Verify values of parameter

"St1"

Door switch contact is open

Verify door switch

Controller doesn't work

Replace controller

Internal fan works, external fan

and compressor don't work.

Display shows alternating OFF

and temperature

The sequence of the phases

inside the power supply

connector is incorrect

Change phases inside power

supply connector

Unit

doesn't

cool

External and internal fan work,

compressor does not work

Compressor motor electrical

failure

Have compressor replaced

by qualified service technician

Capacitor for compressor failed Replace capacitor

Compressor works, external fan

doesn't work

External fan needs to be

replaced

Replace external fan

Enclosure

temperature

too hot

Compressor and fans (external

and internal) work all the time

Cooling unit undersized

Enclosure needs a cooling

unit with with higher capacity

Compressor and external fan

work in alternating mode

(ON / OFF)

Thermal compressor protector

triggered

Verify if ambient temperature

is too high,clean condenser

Refrigerant leakage

Contact dealer/service center

Excessive

condensate

Enclosure door open

Ambient air gets into the

enclosure

Ensure door is closed, add

a door switch and connect

it to controller

Enclosure door closed

Enclosure IP protection class

is below IP54

Seal all openings of the

enclosure

Damaged or misplaced sealing

strip

Repair sealing strip

accordingly

17. Maintenance & Cleaning

Always switch power supply off before starting any maintenance on the unit.

The cooling unit is generally maintenance free and can be operated without filters in most environments. For

units with filters these should be checked, cleaned and if necessary replaced on a regular basis. In addition the

unit should have regular functional tests (approx. every 2,000 hours depending on the grade of ambient

pollution).

Disposal