TECHNICAL GUIDE

Cal. V157A/V158A

0/8

ql

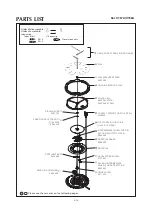

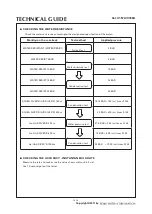

RECHARGEABLE BATTERY UNIT

• How to remove

Remove the battery lead terminal screw, and then

pry up the “A” portion in the illustration with tweezers

to remove the rechargeable battery unit.

• How to install

Set the “B” portion of the battery lead terminal to the

guide hole of the main plate, and then push the center

portion of the rechargeable battery unit (the “C”

portion in the illustration) to fix it in position.

Battery lead terminal

Notes:

• Be sure to observe the correct polarity of the

rechargeable battery unit. The (-) side has the lead

terminal.

• Handle the rechargeable battery unit with care so

as not to short-circuit its (+) and (-) terminals.

“c” portion

rechargeable battery unit

wd

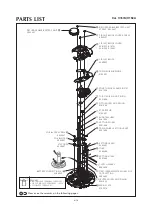

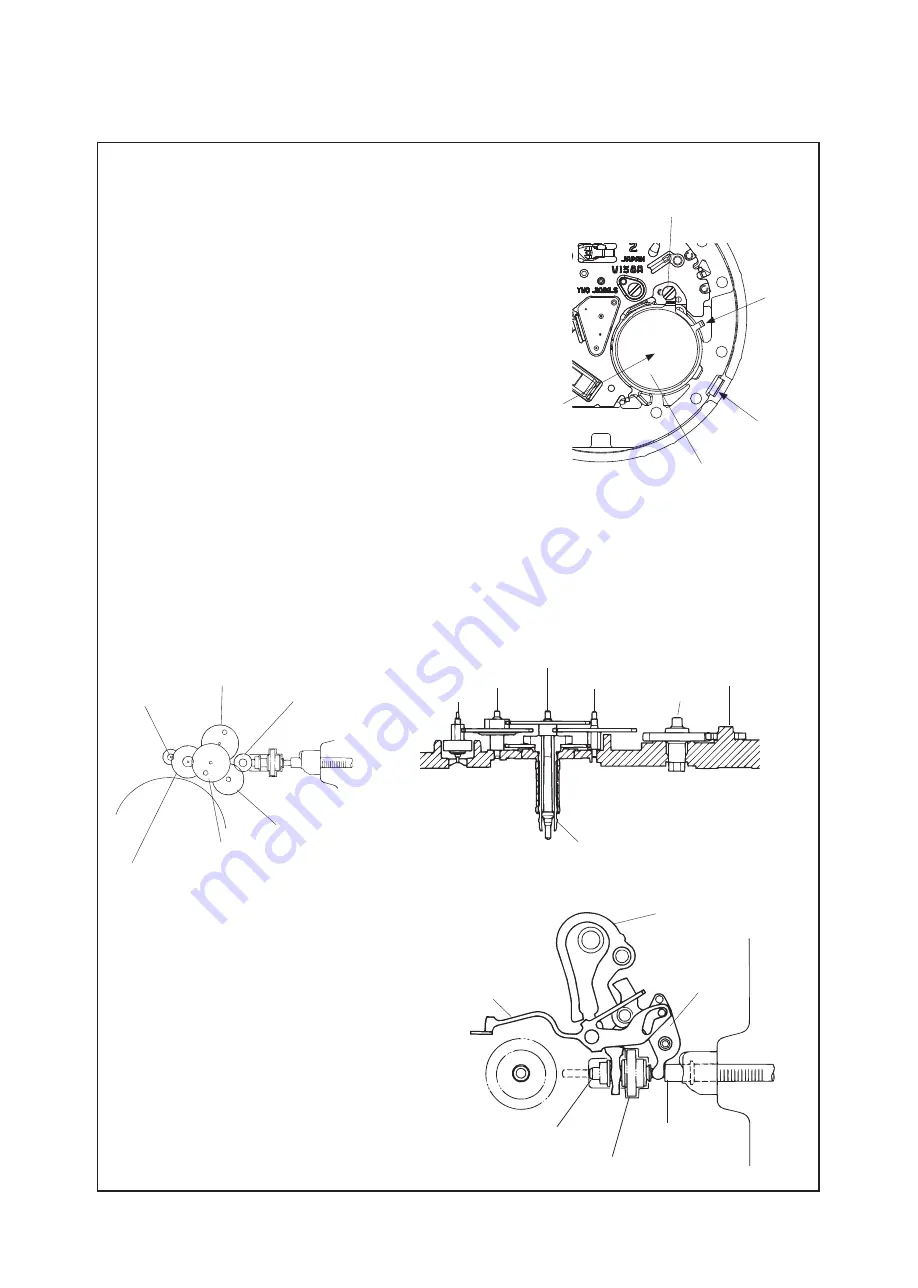

TRAIN WHEEL BRIDGE

fourth wheel and pinion

minute wheel

Refer to the illustrations below to check where to install the respective wheels.

step rotor

third wheel and pinion

setting wheel

fifth wheel and pinion

step rotor

fourth wheel and pinion

fifth wheel and pinion third wheel and pinion

minute wheel

setting wheel

e;

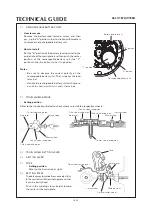

TRAIN WHEEL SETTING LEVER

ef

SETTING LEVER

eg

YOKE

• Setting position

Refer to the illustration at right.

setting lever

• Setting position

yoke

train wheel setting lever

center wheel and pinion

“B” portion

“a” portion

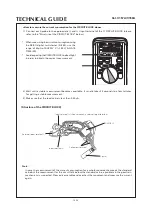

The date corrector wheel has some elasticity

in the contact with the winding stem so that

it can be easily fixed.

Push in the winding stem straight toward

the center of the main plate.

eh

SETTING STEM

winding stem

date corrector wheel

clutch wheel