TECHNICAL GUIDE

Cal. V172A/V174A

23/25

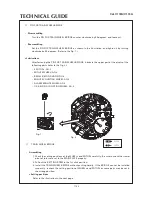

Note: In case the measurement of the voltage for the watch does not achieve the standard value but

the measurement for the solar cell unit alone exceeds the standard value, a problem in the electrical

conductivity between the solar cell unit and the movement is suspected. Inspect the electrical

conductivity, especially at the CONTACT SPRING FOR SOLAR CELL, and check the solar power

generation system again.

<How to check the solar power generation with the SOLAR CELL alone>

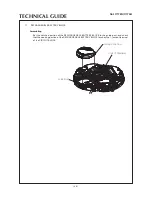

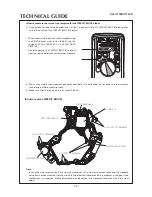

1) Set the SOLAR CELL to the HOLDING RING FOR DIAL.

2) Connect the tester as the below illustration.

* When measuring the voltage using the SEIKO digital

multi-tester (S-860), use the range of V

.

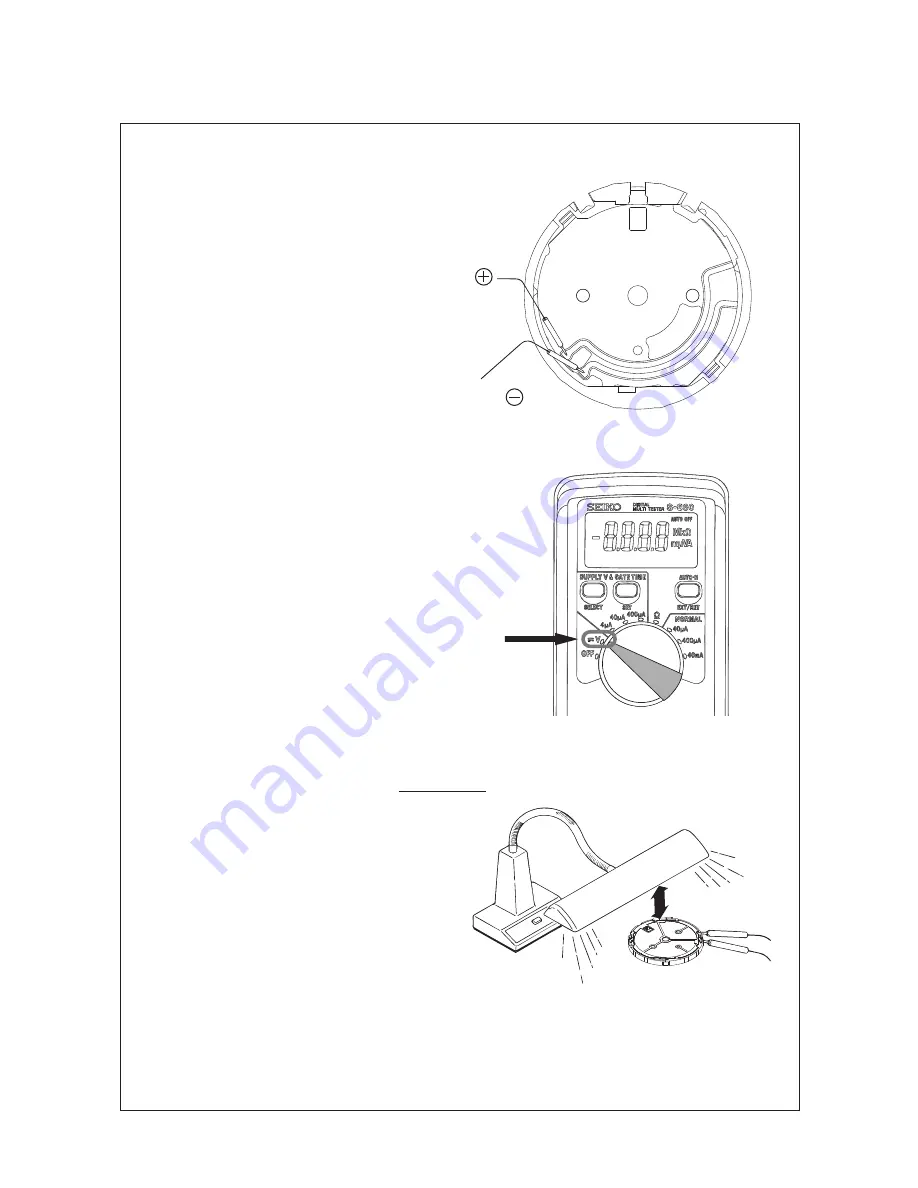

2) Expose the SOLAR CELL to the light of a fluorescent lamp (use the one with 15 to 20 watts) at a

distance of 5-10 cm while connecting the probes to the solar cell unit (Fig. 7.)

3) Read the measurement and check if it exceeds 1.8 V.

5-10 cm

FLUOREScENT LAMP

15 - 20 W