Installation Instructions TM50/TM80 - MO911/1V0

Page 14

Programming

Automatic Closing

!

WHEN USING THE AUTOMATIC CLOSING FEATURE A PHOTO-CELL MUST BE CONNECTED. A PHOTO-CELL IS A

NON-CONTACT SAFETY DEVICE AND WILL AVOID IN MOST CASES THAT USERS, CARS OR OTHER OBSTACLES

WILL BE HIT BY THE CLOSING GARAGE DOOR!

The closing procedure will be started automatically after the pre-set time; the door might be unattended at that time� Wit-

hout a photo-cell the operator will only reverse when hitting an obstacle� Especially moving cars may cause severe damages

on both, car and garage door!

1

Setting the time

Automatic closing is disabled by factory presetting� Setting the time after which the automatic closing shall start enables the

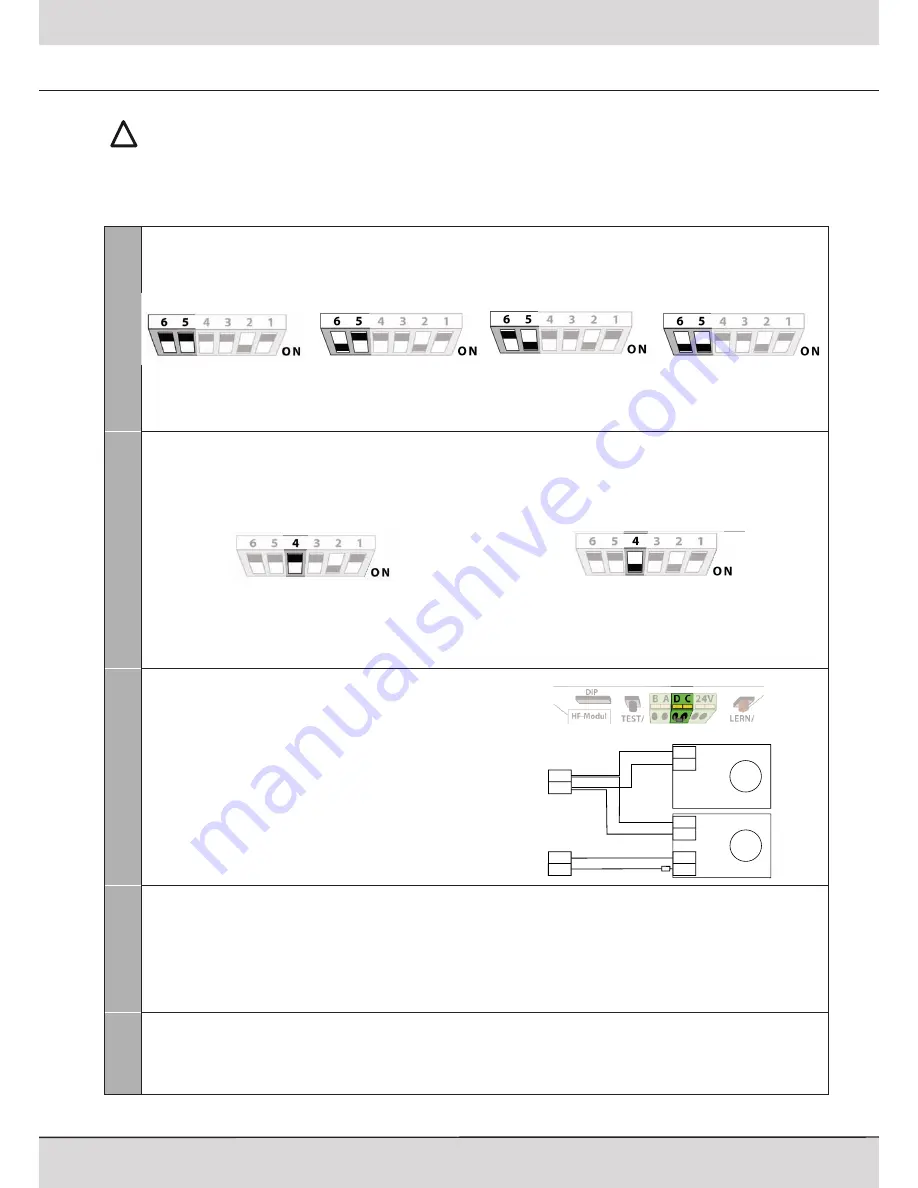

feature� DIP-switches 5+6 must be used for the time setting:

disabled

after 30 seconds

after 90 seconds

after 120 seconds

After changing the DIP-switch settings the red LED will start blinking in intervalls� Shortly press the red LEARN-button to

confirm the new settings; the LED stops blinking and the automatic closing is now active�

2

Pre-Warning by internal lighting

When automatic closing is active the operator will allways pre-warn the users by a blinking internal lighting� The operator

will start closing the door after 6 seconds of pre-warning� By means of DIP-switch no� 4 the pre-warning can additionally be

enabled before openings:

Pre-warning before closings

Pre-warning before closings

Pre-warning before openings and closings

Pre-warning before openings and closings

Pre-warning before openings and closings

External warning lights may connected together with the integrated operators lighting using the connectors 5+6 (230V,

160 Watts max�)� The operators housing must be removed in order to access the connectors�

Cabling and connections of

230V components may only be done my authorised professionals.

3

Connecting a Photo-Cell

As a non-contact safety device a photo-cell must be connect

when using the automatic closing feature�

When the door is open and an obstacle is detected by the

photo-cell then the operator will not start the automatic

closing procedure�

When an obstacle is detected during the closing procedure

then the operator will reverse to fully open and it will restart

the count-down for automatic closing� It will then start the

closing procedure again�

D

C

24V

24V

24 V

24 V

N.C.

8,2 k

W

4

Performance of Control Devices

When the automatic closing is active all incoming commands during the opening cycle will be ignored - the operator will

keep running until to fully open position�

Interrupting the opening procedure will only be possible by:

- Force detection (e�g� obstacle)

- Detection by Photo-Cell/Hatch Door connector for approx� 2 seconds after starting the opening procedure

When the door is in fully open position incoming commands will restart the count-down for the automatic closing, e�g� the

time will be extended�

5

Avoiding automatic closing temporarily

If the user would occassionally like to prevent the door from automatically closing, then an ordinary wall switch can be

connected to the push-button connectors A+B� The operator will remain blocked as long as the wall switch is switched on;

when switching it off the operator will close the door automatically again� A wall switch may be connected alongside a wall

push-button�

www.thegaragedoorcentre.co.uk

0800 525 442

www.thegaragedoorcentre.co.uk

www.thegaragedoorcentre.co.uk

0800 525 442

www.thegaragedoorcentre.co.uk