DR

R42

M

0

0

0

1

A

N 0

3

3

6

0

0

2

81

1

1

9

6

features a configuration menu where you can customize the

regulation parameters that will be transmitted to the receiver and

stored during the "test" mode procedure.

It is possible to configure the type of regulation even when using a

non configurable thermostat (i.e. DTPF85BC) in this case you have

to temporarily learn the address and configure the output with a

display thermostat, then you learn the address of the final non

configurable thermostat.

The receiver maintains the output configuration of the display

thermostat even when a new non configurable thermostat is

learned. In case you have customized the output and you want to

return to the factory default ON/OFF configuration it is necessary

to do a factory default reset.

FACTORY DEFAULT RESET

A factory default reset clears the non-volatile memory of the

device deleting any address learned with the self-learning

procedure and restoring the default ON/OFF output configuration

with predefined hysteresis.

To factory reset:

- Power down

- Press and hold both buttons

and Fig.1

- Power on

- Wait until the LEDs blink

- Release the buttons

REGULATION WITH DEAD BAND

The receiver can be set on jumper JP1 to regulate with dead band

(see step 7 under "Installation").

When regulating with dead band, the receiver drives the “heat”

valve with the relay of channel 1 and the “cool” valve with the

relay of channel 2.

When regulating with dead band, the receiver can learn only one

thermostat on channel 1 and the thermostat will drive both relays

of channel 1 and channel 2. If the setpoint temperature is greater

than the room temperature there is a “heating” request and the

“heat” valve on relay 1 will be turned on, conversely, if the

setpoint temperature is lower than the room temperature there is

a “cooling” request and the “cool” valve on relay 2 will be turned

on. If the room temperature matches the setpoint temperature

both outputs remain off. More in detail the width of the dead band

determines the temperature range in which the outputs remain

off. The dead band‘s width can be set on the trimmer with a small

screwdriver in the range 1 to 11 °C (see step 8 in "Installation").

The heating output will be activated when the room temperature

is below the setpoint temperature of half the dead band, while the

cool output will be activated when the room temperature will be

higher than the temperature setpoint of half the dead band.

When in dead band regulation it is assumed that the heating and

cooling systems are always available and the heating/cooling

status of the transmitter will be ignored, as it is the room

temperature that will determine whether to heat or to cool.

When in dead band regulation, the “test” mode of the thermostat

will toggle every 2 seconds only output 1 (heating).

When the receiver is set for dead band regulation, it can not

perform the lower and upper floor temperature limitation that can

be set on TRD01B and DCW01B thermostats.

TROUBLESHOOTING

SYMPTOM

:

The receiver appears completely “dead”.

PROBABLE CAUSE

: There’s no mains power.

REMEDY

:

Check the mains power connection.

Usually LEDs may remain off, but they

perform a blinking sequence “green-red-

green-red” when the receiver is switched on

to indicate correct operation.

SYMPTOM

:

One of receiver’s LED continuously blinks

green.

PROBABLE CAUSE

: The device is signaling a fault because it has

detected an error in the temperature probe

of the wireless thermostat or programmable

thermostat.

REMEDY

:

Check the temperature probe of the

transmitter and, if present, the jumper for

selecting between the internal and external

probe. Carefully read the instructions of the

transmitters for further information.

SYMPTOM

:

One of receiver’s LED continuously blinks

yellow.

PROBABLE CAUSE

: The device is signaling a fault because it has

detected the wireless thermostat or

programmable thermostat batteries to be

running low.

REMEDY

:

Replace the batteries of the transmitters

concerned. Carefully read the instructions of

the transmitters for further information.

SYMPTOM

:

One of receiver’s LED continuously blinks

red.

PROBABLE CAUSE

: The channels in question are in an “alarm

status” due to the absence of radio

communication.

REMEDY

:

Check the radio communication again using

the “test” function on the transmitter.

Assess whether the devices need to be

moved away from metal shields or a

“repeater” needs to be installed.

SYMPTOM

:

When starting the self-learning procedure,

the receiver does not blinks the LED yellow.

PROBABLE CAUSE

: The self-learning button has been pressed

too quickly.

REMEDY

:

Start the self-learning procedure keeping

pressed the self-learning button for one

second.

SYMPTOM

:

The transmitter is in the “test” mode but

the receiver fails to switch on any relay.

The LED does not indicate any reception of

commands via radio.

PROBABLE CAUSE

: The signals received are too weak to enable

correct decoding of the commands .

REMEDY

:

Assess whether the devices need to be

moved away from metal shields or a

“repeater” needs to be installed.

SYMPTOM

:

The receiver’s LED remain red despite the

communication with the transmitter had

been restored.

PROBABLE CAUSE

: The long-term analysis of the signal quality

reports the history of the last 90 minutes of

the channel activity.

REMEDY

:

Verify with the “test” mode that the

“immediate” indication on the LED indicates

a sufficient signal quality and allow up to

90 minutes for the long-term analysis to

turn green.

TECHNICAL FEATURES

Power supply:

230V 50Hz / 24V

Absorption:

11VA

Relay contacts ratings:

2 x 6(4)A 250V (voltage free)

Regulation hysteresis :

0,3°C

Frequency:

868,150 MHz

Sensitivity:

-105 dBm

Modulation:

GFSK

Bandwidth (-3 dB):

100 KHz

Type of antenna:

internal stylus

Max. distance from transmitter: >300m in free field

>50 m in buildings (depending

on the building and environment)

Protection rating:

IP 3X

Type of action:

1

Overvoltage category:

II

Pollution degree:

2

Tracking index (PTI):

175

Class of protection

against electric shock:

II

Rated impulse voltage:

2500V

Number of automatic cycles:

100000 (diagrams on Fig. 7, 8,

9, 10)

Software class:

A

EMC test voltage:

230V 50Hz

EMC test current:

45 mA

Distances tolerances fault

mode ‘short’ exclusion:

±0,15 mm

Ball pressure test temperature: 75 °C

Operating temperature:

0°C .. 40 °C

Storage temperature:

-10°C .. +50 °C

Humidity limits:

20% .. 80 % RH non-condensing

Enclosure: Material:

ABS V0 self-extinguishing

Color:

Signal White (RAL 9003)

(RAL 9003)

Installation:

Wall mounted

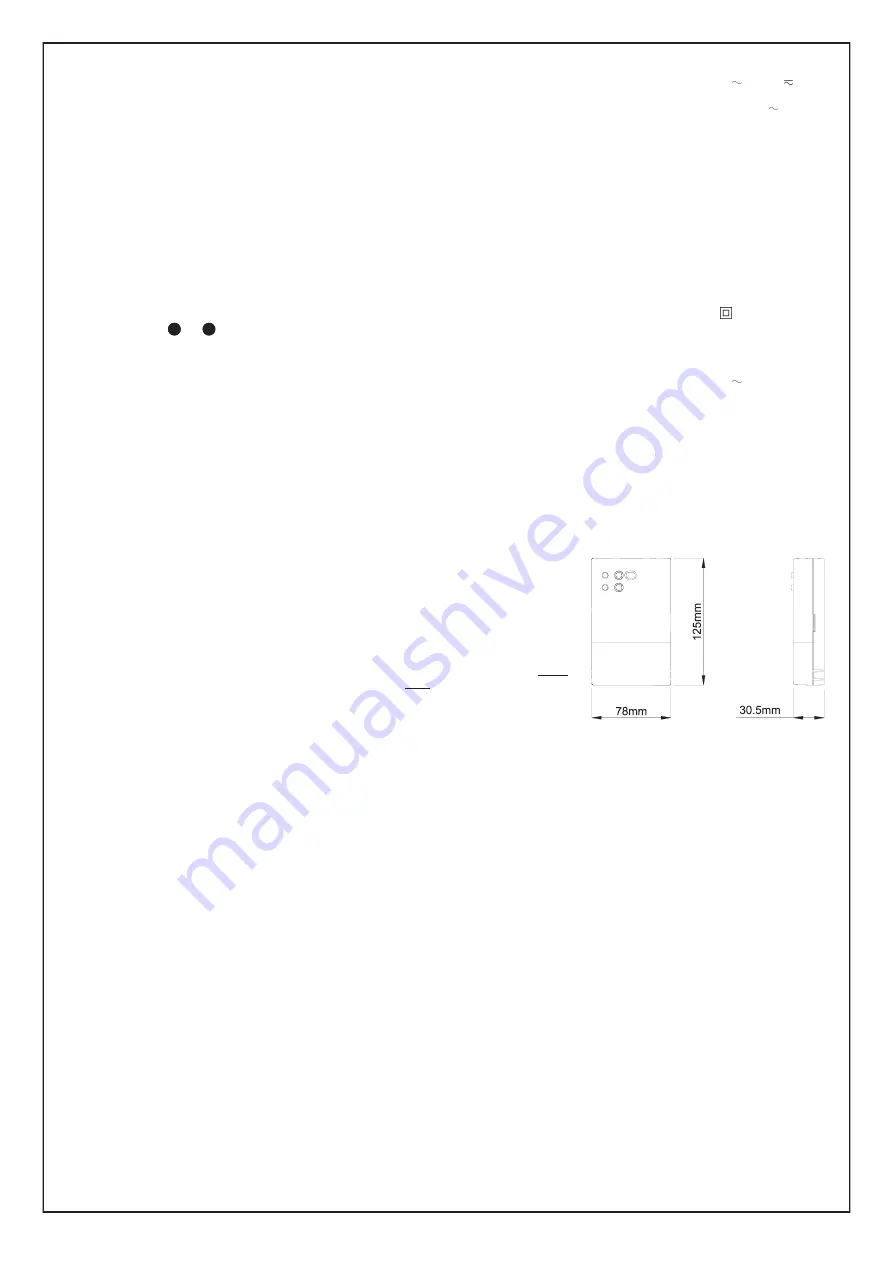

DIMENSIONS

WARRANTY

In the view of a constant development of their products, the

manufacturer reserves the right for changing technical data and

features without prior notice.

The consumer is guaranteed against any lack of conformity

according to the European Directive 1999/44/EC as well as to the

manufacturer’s document about the warranty policy. The full text

of warranty is available on request from the seller.

- ENGLISH -

A

B