500

Allows the selection of the required graphic interface:

XE (Easy Mode)

XA (Advanced Mode)

XP (Professional Mode)

Allows access to the higher set-up levels:

USER:

user

SERV:

service

SELCO:

Selco

551 Lock/unlock

Allows the locking of the panel controls and the inser-

tion of a protection code (consult the “Lock/unlock”

section).

552 Buzzer

tone

Permits adjustment of the buzzer tone.

Minimum Off, Maximum 10, Default 5

553 Contrast

Permits adjustment of the display contrast.

Minimum 0, Maximum 50

601

(U/D) Adjustment step

Permits adjustment of the variation step on the up-

down keys.

Minimum Off, Maximum MAX, Default 1

602

CH1, CH2, CH3, CH4 External parameter

Allows the management of external parameter 1 (mini-

mum value, maximum value, default value, parameter

selected).

(Consult the “External controls management” section).

606 U/D torch

Allows the management of the external parameter

(U/D). 0=Off, 1=A

751 Current

reading

Allow the real value of the welding current to be dis-

played.

Allows the welding current display method to be set.

752 Voltage

reading

Allows the real value of the welding voltage to be dis-

played.

Allows the welding voltage display method to be set.

801 Guard

limits

Allows the setting of the warning limits and of the guard

limits.

Allows the accurate control of the various welding

phases (consult the “Guard limits” section).

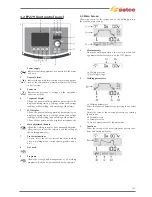

3.5 Programs screen

1 General

Allows the storage and management of 64 welding pro-

grams which can be personalised by the operator.

1 Process of the selected program

2 Welding methods

3 Current pulsation

4 Number of the selected program

5 Main parameters of the selected program

6 Description of the selected program

7 Measurements

2 Program

storage

Enter the “program storage” menu by pressing button

for at least 1 second.

Select the required program (or the empty memory) by

rotating the encoder.

Program stored

Memory empty

Cancel the operation by pressing button (2)

.

129

Summary of Contents for Genesis 1700 AC/DC

Page 1: ...Genesis 1700 AC DC Genesis 2200 AC DC MANUALE DI RIPARAZIONE REPAIR MANUAL ...

Page 51: ...161 PFC S POWER COMPONENTS D11 IG1 IG2 D1 D7 CN3 M1 CN4 CN5 CN8 CN7 M2 CN6 ...

Page 52: ...162 PFC STAGE LEDS INDICATIONS PFC s POWER COMPONENTS L2 L1 IG1 IG2 D1 CN6 D7 D11 ...

Page 54: ...164 INVERTER STAGE CN3 M1 CN4 CN5 CN8 CN7 M2 Inverter IMS power module ...

Page 62: ...172 15 Remove pcb T3 PFC s POWER COMPONENTS IG1 IG2 D1 NTC1 Unscrew torque screw at 2 2N mt ...

Page 64: ...174 DIODES AND PFC IGBT ORIENTATION Landmark for assembling ...

Page 67: ...177 12 4 Thermic caps inverter side NTC1 T3 CN11 ...

Page 69: ...179 12 5 Thermic caps secondary side T1 T2 15 14 434 CN3 CN2 ...

Page 74: ...184 15 14 439 15 14 42901 L3 L4 L1 L2 ...

Page 75: ...185 Gas valve flow chart signal Pipe 38 39 ...

Page 79: ...189 CN6 15 14 415 CN3 15 14 431 FLAT A FLAT B Inverter commands Boost commands ...

Page 80: ...190 By pass relais flow chart Gas valve ELVI Fan M1 and M2 command signal ...

Page 81: ...191 HF command signal AC command signal Torch switch buttons signals ...

Page 88: ...198 HF pulse in TIG AC HF pulse in TIG DC ...

Page 114: ...224 GENESIS 2200 AC DC FP279 ...

Page 115: ...225 GENESIS 1700 AC DC FP216 ...

Page 116: ...226 GENESIS 2200 AC DC FP216 ...

Page 118: ...228 20 CONNETTORI CONNECTORS GENESIS 1700 AC DC FP279 GENESIS 2200 AC DC FP279 ...

Page 119: ...229 GENESIS 1700 AC DC FP216 GENESIS 2200 AC DC FP216 ...

Page 122: ...232 55 08 022 55 08 023 GENESIS 1700 AC DC FP216 GENESIS 2200 AC DC FP216 ...