22

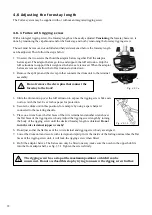

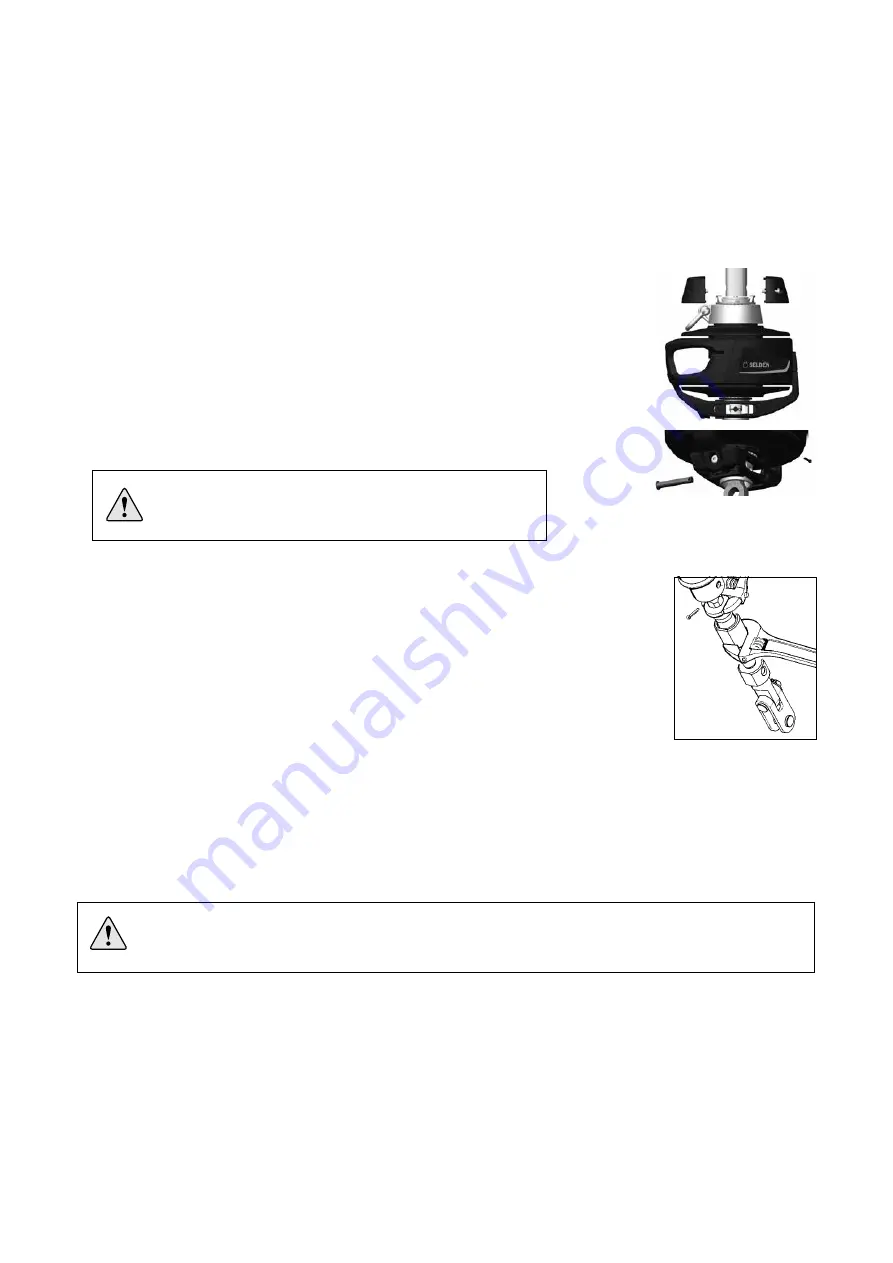

4.6 Adjusting the forestay length

4.6.1 Furlex with rigging screw

The Furlex system may be supplied with or without an integrated rigging screw.

With an integral rigging screw, the forestay length can be easily adjusted.

Tensioning

the forestay however, is

done by tensioning the cap shrouds and/or the backstay, and not by tensioning the forestay rigging screw.

The sail must be removed or unfurled and halyard slackened before the forestay length

can be adjusted. Then follow the steps below:

1. Unscrew the two screws that hold the adaptor halves together. Pull the adaptor

halves apart. The adaptor halves go into, and support, the luff extrusion. Grip the

luff extrusions to support their weight as the halves are removed. When the adaptor

halves are removed, allow the luff extrusions to slide down.

2.

Remove the split pin and the clevis pin that connects the drum unit to the terminal

assembly.

3. Slide the drum unit up over the luff extrusion to expose the rigging screw. Take care

not to scratch the foil. Use cloth or paper for protection.

4. Secure the drum unit in this position, for example by using a spare halyard

connected to the tack ring shackle.

5.

Place one wrench over the flat faces of the wire terminal and another wrench over

the flat faces of the rigging screw body. Adjust the rigging screw length by turning

the body of the rigging screw until the desired forestay length is obtained.

Do not

turn the wire terminal (upper wrench)!

6.

Re-adjust so that the flat faces of the wire terminal and rigging screw body are aligned.

7.

Lower the drum unit and secure with clevispin and split pin. As the inside of the furling unit matches the flat

faces of the rigging screw unit, it will lock the rigging screw when fitted.

8.

Re-fit the adaptor halves. The halves can only be fitted one way; make sure the notch in the upper hub fits

into the front adaptor half, see fig. 3.5.f. Tighten the screws firmly.

Do not remove the clevis pins that connect the

forestay to the boat!

The rigging screw has a stop at the maximum position to which it can be

unscrewed. Do not overload this stop by trying to unscrew the rigging screw further.

Fig. 4.6.1.a

Fig. 4.6.1.b