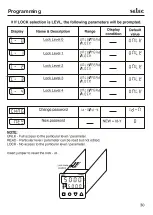

The Zone set points may be programmed as:

Note: • Set1 < Zone setpoint 1.

!

Zone PID:

• The PID settings derived after tuning are stored in Zone 2.

O

• After tuning, for 150 < Set1 < 450 C, PID settings of Zone 2 are applicable.

O

2. Zone setpoint 2 (Level1) : 450 C (This implies that for 150 < set1 < 450, Zone2 PID

O

1. Zone setpoint 1 (Level1) : 150 C (This implies that for 0 < set1 < 150, Zone1 PID

There are 4 control Zones each having a set point and associated P, I and D values which

can be programmed as per the process requirements. A control Zone is selected

automatically and implemented as per the set value programmed, to accommodate

changing process requirements. The corresponding P, I,D values will be used to control

the process. The main advantage of Zone PID is in processes where there is a

requirement of frequent tuning, due to change in setpoint. Consider a case where the

O

O

process needs to be controlled at two different set points: 100 C and 400 C.

values will be considered.)

NOTE : Zone setpoint is not the tuning setpoint.

• The PID settings derived after tuning are stored in Zone 1.

3. After tuning the controller is automatically loaded with the new PID values.

Now to tune the next Zone, Zone 2, program the following:

O

O

1. Set 1 (Online) = 400 C (Zone 2 :150 - 450 C)

Note: • Zone Setpoint 1 < Set 1 < Zone setpoint 2.

To tune, say, Zone 1 program the following:

How to tune the Zones

O

• After tuning, for 0 < Set1 < 150 C, PID settings of Zone 1 are applicable.

The P, I, D values for the respective Zones can be manually fed or can be tuned

automatically.

values will be considered.)

O

O

1. Set1 (Online) = 100 C (for eg.) (Zone 1 : 0 - 150 C)

2. Program Tune = ON (in Level 1 or Online)

Similarly, the four different Zones can be programmed.

37

User Guide