4

Safety Information

The pump is designed and manufactured solely

for the purpose of pumping water for fire

fighting, tank filling or similar activities. Under

no circumstances should it be used for pumping

flammable or corrosive liquids such as petrol or

chemical solutions.

Before using the pump carefully read and

ensure you understand the contents of this

manual. Ensure that you are familiar with the

starting, operating and stopping procedures.

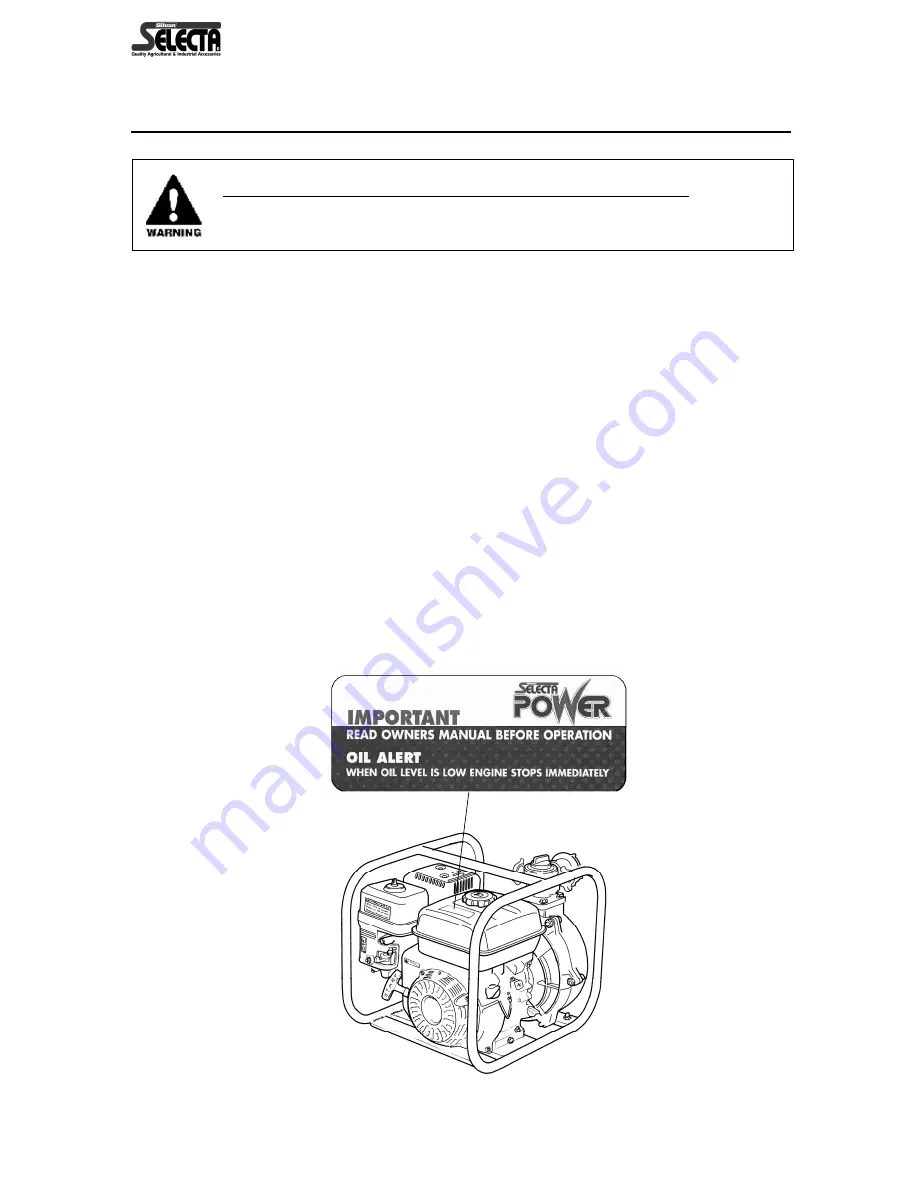

Before using the pump ensure all operators

read and follow the safety warning carried on

the machine. Refer below for the wording of this

warning.

Never allow an inadequately trained person to

operate the pump

Do not operate the pump whilst wearing loose

clothing, unrestrained long hair, jewellery or

anything which could become entangled in

rotating components or limit your vision.

Always operate the pump in a well ventilated

and well lit area that is free from flammable or

other materials that may interfere with its safe

operation. Never operate in an enclosed area

as engine exhaust fumes contain carbon

monoxide, an odourless tasteless asphyxiant,

which could cause unconsciousness or death.

Always operate on firm and level ground.

Uneven or sloping terrain could lead to the

pump overturning and spilling fuel.

Never leave the pump unattended while the

engine is running.

Stop the engine before doing any maintenance

work on the pump.

Avoid contact with hot engine parts, which

could cause serious burns.

Keep bystanders, children and animals away

from the pump whilst operating.

Before operating the pump read the following safety instructions.

Failure to comply with these warnings may result in serious injury or death.

Whilst your Pump has been designed and manufactured to incorporate all necessary

safety features it is essential that any person who operates or works on the machine is

aware of the safety precautions that should be exercised.