www.FreeStyleFlooring.com

www.StaticStop.com

©2019 SelecTech, Inc. All Right Reserved

Selec

Tech

by

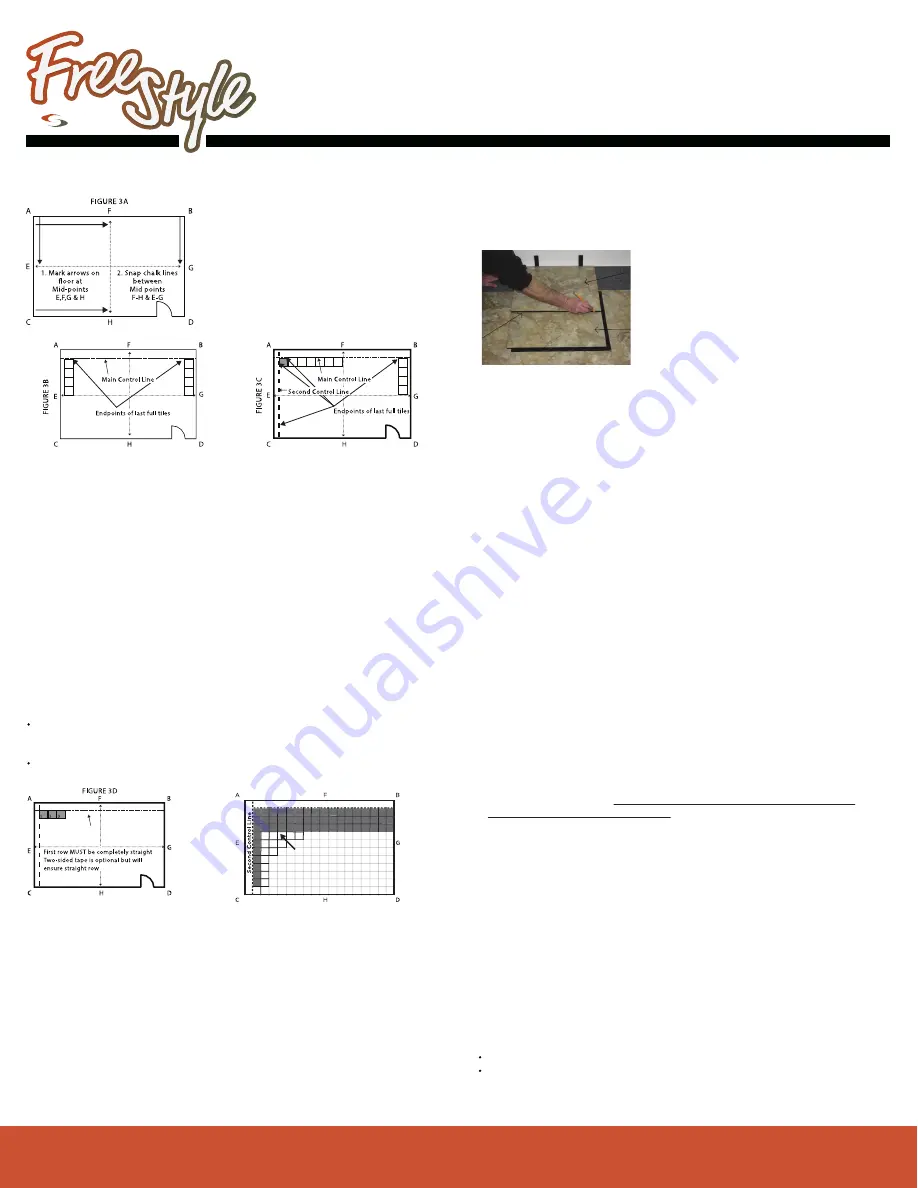

Establish Midlines and Midpoint of Room (FIGURE 3A)

• Measure from point A to B. Record that measurement and divide it by 2

• Starting at Point A, measure to find the

halfway point on wall AB.

• Mark that Midpoint with an arrow, as accu-

rately as possible. (See Point F)

• Repeat Steps 1 & 2 along wall CD.

• Snap a chalk line between these points,

shown as line FH.

• Repeat the process to find the midpoints

on wall AC and wall BD.

• Snap a chalk line between these points,

shown as line EG in Figure 2

Establish Control Lines and Starting Point (FIGURE 3B &3C)

Install The Control Row (FIGURE 3D)

• Starting at Midline EG along Wall AC lay full tiles as shown to the point

where a full tile will not fit.

• Carefully mark a the point at the Finished Edge of the last tile. Note: You

must mark that line at the Finished Edge of the tile, not at the edge of the

Interlock Extensions. (See FIGURE 1)

• You may either repeat the process, laying tiles along the opposite wall or

multiply the number of full tiles by 18.5. Measure that length from the Midline

to the wall and mark that point along the opposite wall.

• Snap a chalk line between these two points. This is the Main Control Line for

your installation.

• Repeat the process along the other walls to determine the number of full

tiles. That chalk line will be your Second Control Line.

• The corner formed where the Main and Second Control Lines meet is the

Start Point for your installation.

Complete Field Tile Installation (FIGURE 3E)

Simpler Installation

Grounding FreeStyle ESD

Care, Maintenance, and Additional Information

It is essential to keep the first row straight on the Control Line. This will keep

the installation square and ensure easy installation. Failure to do so may cause

gapped or excessively tight seams as you add rows.

Create a Template to Cut Edge Tiles

•

Create an End Cut Template by cleanly

removing the interlock extension from one tile.

•

Beginning in a corner, place a loose tile over

the installed corner tile.

•

Line up the edges precisely.

Be sure the interlocks are oriented the

same way as the installed tile.

•

Lay the End Cut Template over the loose tile

to be cut. Butt the template against the wall, placing 1/4” spacers

near the corners (you may use a “slice” of a tile to achieve a 5/16” space).

Line up the other edges and mark a line where the template meets the

loose tile.

•

Remove the marked tile and cut along the drawn line.

•

If required, gently lift the edge of the “field tile” and slide the cut tile Inter

Interlock Extension under the “field tile”. Butt tiles together and align corners.

Seat the tile corner with the heel of your hand. Use a dead blow hammer to

finish seating the edges. Check to ensure minimum expansion space

along the wall.

•

Continue using this method around the perimeter of the room until all tiles

are installed.

Settling Seams

Door Jambs

Detail Cuts

Due to the tight seam design, tiles may initially pop up during installation. For

best interlock joint seating, roll over all joints with a roller, applying pressure

to the joints as you roll across them. You may repeat this process after the

floor has had a chance to “settle in” for a few days. You may also go back over

the floor re-tapping any high points with the dead-blow hammer.

Transitions and Relief Joints

To transition to the sub-floor or to adjacent flooring install a transition piece.

SelecTech has a number of transitions and edge piece accessories available

for most situations. See FreeStyle Technical Bulletin 060114-FreeStyle

Standard Reducers and Transitions for recommended options.

Rolling Loads

For unusual conditions or extraordinary installations contact

SelecTech for guidance (877-738-4537)

Install ROW 1 carefully along the Main Control Line. Before starting ROW

2, CLOSELY check ROW 1 and adjust as needed to keep it on the Main

Control line

Install a 2nd row.

Once you have installed 2 or 3 rows assemble a number of tiles along the

Second Control Line, perpendicular to the Main Control Line. Check for

squareness of the assembled tiles. Then complete installation of the field

tiles in a “pyramid” pattern as shown in Figure 3E. This will help maintain

square during the installation. Continue to add tiles along the Second

Control Line and then fill field tiles until field tile installation is complete.

Edge cuts should not be smaller than six inches. Once you have

established your Control Lines, if you find that the distance between either

of the Control Lines to the wall is less than 6” you may want to begin with

a full tile close the wall. In this case, or if you simply prefer the simpler

installation with less cutting, follow all of the steps above.

It is recommended that a copper grounding wire be placed at least every

1,000 square feet,throughout the installation. FreeStyle Grounding kits can

be ordered from SelecTech. For additional information on grounding: visit

www.staticstop.com

For detailed care and maintenance, warranty information, grounding

instructions for ESD tiles, and other technical guidelines,

visit the tech documents page on our websites:

For Freestyle and FreeStyle Biolock visit www.freestyleflooring.com

For FreeStyle ESD, ESD Plus and Designer Series visit

www.staticstop.com

You will still establish two Control Lines but one or both of them will be

close to the wall (leaving at least a 1/8” gap between the tile edge and the

wall for expansion). In this case measure from each of the points marking

the end of the last full tile to the wall. Snap a chalk line along the wall. This

is your starting line.

Measuring, Cutting, and Laying Cut Tiles Around Perimeter

For the best finish you will need to cut the door jamb moldings so the tiles fit

freely under them. This is easily done with a “door jamb” or “undercut” saw

available at most hardware stores. Cut the jamb using a tile to establish the

proper cutting height. Note: In some cases you will also have to cut the door

bottom due to inadequate clearance. Your door should not rub anywhere on

the tile when it is open and shut.

The thickness of FreeStyle makes it difficult to cut by hand. A jigsaw is

recommended for more detailed cuts. Heating the tile with a heat gun also

makes it easier to cut.

Heavy rolling loads in commercial environments can cause the tiles to

compress and creep, and come unsnapped along traffic areas and

particularly at turning or pivot points. To prevent this apply a releasable

adhesive (Parabond M5080, or equal) in these areas only. Follow adhesive

manufacturer’s instructions for application. Alternatively, apply a grid of a

2-sided tape such as 1” Ultrastik (available from SelecTech) or equal in the

high traffic areas.

FIGURE 3E

Main Control Line

Once Main Control Line and

Second Control line tiles are

in place complete installation

in “pyramid” fashion.