M 9 6 5 2 7 1

Fig. 1e

Fig. 1f

8

10

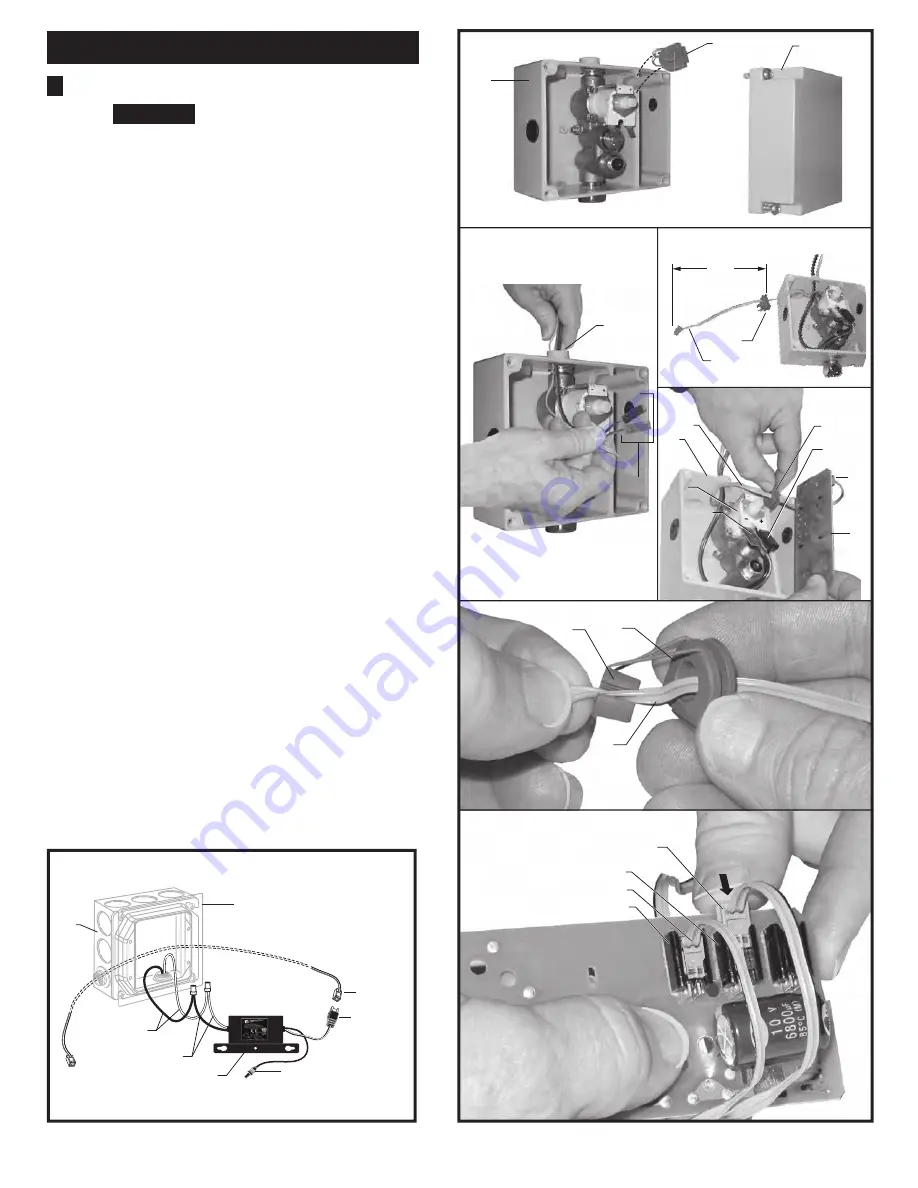

ELECTRICAL INSTALLATION

4

Fig. 1

Fig. 1b

1.

Remove ENCLOSURE COVER

(1)

.

Fig. 1.

2.

Feed the WIRE CONNECTORS

(2)

through the top

of ENCLOSURE

(5)

.

Fig. 1a.

3.

Remove GROMMET

(4)

from ENCLOSURE

(5)

.

Fig. 1.

4.

Feed the gray SENSOR WIRE

(7)

through

GROMMET

(4)

, 4" from CONNECTOR.

Fig. 1b.

Insert

gray SENSOR WIRE

(7)

into SPLIT PLUG

(9)

. Push

SPLIT PLUG

(9)

into GROMMET

(4)

to seal.

Fig. 1d.

5.

Insert GROMMET

(4)

back into ENCLOSURE

(5)

.

Fig. 1c.

6.

Install CIRCUIT BOARD

(3)

into ENCLOSURE

(5)

with SENSOR WIRE

(7)

under BOARD.

Fig. 1c.

7.

Insert SENSOR WIRE CONNECTOR

(8)

and

EXTENSION WIRE CONNECTOR

(11)

into available

CIRCUIT BOARD RECEPTORS

(10)

slots.

Fig. 1e.

8.

Connect wires from SENSOR to SOLENOID VALVE

(6)

(Red to +, Black to -).

Fig. 1d.

9.

Replace ENCLOSURE COVER

(1)

. Tighten cover

screws firmly.

10.

Contractor to supply ELECTRICAL BOX (12)

and connection to ENCLOSURE (5).

Mount POWER

SUPPLY

(13)

into ELECTRICAL BOX

(12)

. Connect

White and Black power connections to POWER

SUPPLY CABLE

(14)

.

Fig. 1f.

11.

Connect the EXTENSION WIRE

(16)

to the

POWER SUPPLY CABLE

(15)

.

FIG. 1f.

ELECTRICAL CONNECTIONS; Fig. 1

1

4

8

RED

6

Fig. 1c

Fig. 1d

7

4

9

1

4

7

5

4

4"

3

CAUTION

Before opening ENCLOSURE

disconnect AC power supply.

BLACK

F

5

2

Fig. 1a

5

7

10

BLACK & WHITE

POWER

CONNECTIONS

15

13

CONNECTOR NOT

USED IN THIS

INSTALLATION

16

14

4" ELECTRICAL BOX

OR EQUIVALENT BY

OTHERS

11

12