Page 14

3. Select the side of the fireplace that the gas conduit is to be

run through, and remove the refractory from that side by

removing the refractory clip. Knock out the remainder of the

hole in the refractory using a hammer and a chisel. There is

also a sheet metal knockout on the outer casing and

firebox lining to be removed.

WARNING: THE OUTSIDE AIR KIT VENT MUST VENT

TO THE OUTSIDE ONLY. DO NOT INSTALL THE

HOOD ASSEMBLY IN A GARAGE, CARPORT, ATTIC,

OR BASEMENT.

4. Locate a position in the outside wall to install the hood

assembly, ensuring the duct is long enough. Cut a hole

through the outside wall approximately 75mm(3") in diameter

and slide the hood assembly in from the outside wall and

seal it with a suitable caulking.

5. Cut the flexible air duct to suit your installation, and attach

both ends using the duct clamps.

FAN KIT INSTALLATION

(See Appendix B)

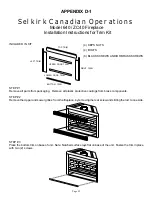

1. The Fan Kit is an option that can be hooked up directly to

any electrical supply at the time of the fireplace installation.

or simply plugged into a nearby electrical outlet if installed at

a later date.

2. The fan is contained in a single mounting unit and has

760mm(30") of electrical wire with a three prong plug attached.

To attach the fan to the fireplace, insert the fan through the

lower grille opening and attach the fan assembly to the

bottom of the fireplace.

3. Your Fireplace has been designed to accept the electri-

cal wiring through either side of the unit by running the elec-

trical wire into or out of the unit through the front support

support channel located on the bottom of the fireplace.

CAUTION: HAVE A CERTIFIED ELECTRICIAN DO ANY

OF THE ELECTRICAL CONNECTIONS OR HOOK-UP OF

YOUR FAN KIT

3. Open the lower grille and slide the air stub and flap

assembly through the hole in the Outer Casing. Ensure that

the flap on the assembly opens so that the air flow is directed

towards the back of the fireplace, and fasten the assembly

to the fireplace with four screws to hold the assembly in

place.

GAS LINE INSTALLATION

1. Your fireplace is designed to accept a 19mm (3/4")

gas line for a decorative gas appliance or a gas log ignitor.

Have the appliance and the gas line installed by a qualified

gas fitter in accordance with all local building codes. The

gas pipe installation is intended for connection to approved

decorative gas appliance or gas log ignitor only in accordance

with CAN\CGA-B149 in Canada, and the National Fuel

Gas Code ANSI Z223.1 in the United States.

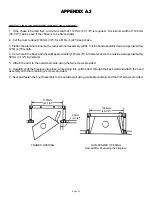

2. In order to install the gas line conduit you will require a

piece of 19mm(¾") nominal diameter nipple 152mm(6")

long and two 25mm(1") diameter electrical conduit locknuts

to fit the pipe.

3. Select the side of the fireplace that the gas conduit is to

4. Insert the pipe so that it passes through both sheet metal

holes and fasten in place using the 25mm(1") diameter nuts.

The pipe should be located so that it will be flush with the

back of the refractory. See figure 25.

5. The gas pipe must be iron or steel pipe, and the gap

around the pipe must be sealed with stove cement where it

passes through the refractory panel.

CAUTION: WHEN A DECORATIVE GAS

APPLIANCE IS INSTALLED IN A FIREPLACE

THAT HAS A MANUAL DAMPER, LOCAL

BUILDING CODES MAY REQUIRE REMOVAL OF THE

DAMPER, OR THAT A PERMANENT STOP

BE PROVIDED ON THE DAMPER TO PREVENT

COMPLETE CLOSURE OF THE FLUE OUTLET.

CHECK WITH YOUR LOCAL BUILDING CODE

OFFICIAL TO DETERMINE WHAT IS REQUIRED

IN YOUR AREA.

OUTER

CASING

AIR SPACE

FIREBOX

REFRACTORY

FIGURE 25