Page 20

120

L2

VAC

G

Selkirk Canadian Operations

APPENDIX B

Model 640 / ZC40 Fireplace

Installation Instructions for Direct Blower Kit

Items included in kit:

1) Blower assembly

3) Electrical junction box cover

5) Variable switch

2) Electrical junction box

4) Blower deflector

6) 30" three prong plug

7) Hardware pack

STEP #1

Remove the bottom grille from the fireplace, by removing the rear screw and sliding the rod to one side.

STEP #2

Place the blower assembly on to the two (2) studs towards the back of the base and fasten with two (2) 10-32 hex

nuts provided.

Make sure the blower is pushed to the rear as far as the slots will allow. Do not overtighten the hex nuts that secure

the blower to the base. The foam gasket should only be slightly compressed.

STEP #3

Install the variable speed/electrical box on the two studs located at the side front of the base (opposite side of air

kit, if used) and securing it with the two (2) 10-32 hex nuts provided. If studs are not present, drill and secure to side

of unit. The speed control may be installed in the junction box or located remotely.

If the speed control is to be located in the junction box, the knock out on the front of the box must be removed. The

speed control is then inserted between the cover plate and the housing of the box. Be sure to align the tabs of the

speed control with the holes that secure the cover plate to the junction box and reassemble.

If the speed control is to be located somewhere else, an electrical junction box not provided must be installed around

the control and the system must be wired in accordance with local and or national electrical codes.

STEP #4

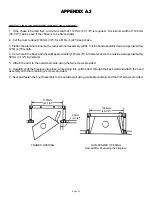

Wire this assembly to a 120 volts power supply. Note: A licenced or qualified electrician must make the power

connection. See figure 1.

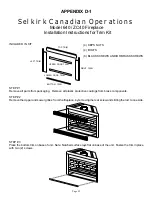

STEP #5

Feed the air deflector into the bottom and lift the air deflector up and position the vee bend into the vee frame of the

blower. See figure 2.

LINE

L1

MOTOR

ON/OFF & VARIABLE

SPEED CONTROL

BLOWER WIRING

DIAGRAM

FIGURE 1

FIGURE 2