GENERAL

Two different types of direct vent conversion systems

are described here. One is through an existing factory

built metal chimney going through the ceiling. The other

is through the wall of an existing masonry chimney. Follow

the appropriate directions for your situation.

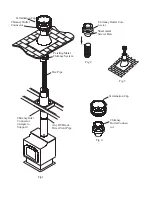

A typical direct vent conversion to a factory built metal

chimney is shown in Figure 1. The concept of direct vent

conversion is to connect an adapter to an Underwriters

Laboratories listed 4” aluminum flex pipe for direct vent

gas appliances. (Selkirk Model AFCL is an example of a

UL listed flex pipe or 4” stainless steel flex pipe for

Direct-Temp for Pellet Stoves applications. Selkirk

Model SFCL is an example of a UL listed stainless steel

flex pipe). The flex is then passed down through the center

of the existing metal chimney system.

The Chimney Inlet Connector is then attached to the bottom

of the flex pipe. Both the Outlet Connector and Inlet

Connector are attached to the existing chimney with sheet

metal screws. The appliance is then connected to the

chimney with appropriate black direct vent pipe, and an

adjustable length section.

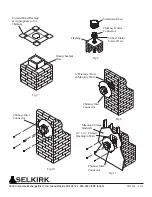

A typical conversion to an existing masonry chimney is

shown in Figure 6. For installation through the wall of an

existing masonry chimney, a Chimney Outlet Connector

and Flashing are used at the top of the masonry chimney.

The flex pipe liner is connected to the adapter and is

passed down the chimney and out through the masonry

wall. This is attached to the Chimney Inlet Connector

which in turn is attached to the masonry wall and is then

connected to the direct vent pipe leading to the appliance.

MODEL DT DIRECT VENT INSTALLATION

INSTRUCTION SUPPLEMENT

ADAPTING MODEL DT TO FACTORY BUILT AND MASONRY CHIMNEYS

CONVERSION TO A FACTORY BUILT

METAL CHIMNEY

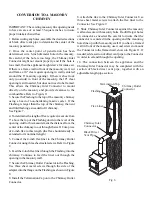

1. Remove the existing chimney cap.

2. Measure the distance from the top end of the chimney

to the bottom of the ceiling support, add 3-inches to this

measurement, and cut a section of flex pipe to that length

(the flex should already be extended to its normal length).

3. Connect the end of the flex pipe section to the underside

of the Chimney Outlet Connector you have selected, using

three sheet metal screws. Refer to Figure 2.

4. Pass the flex pipe down through the center of the

chimney system, and center the Outlet Connector on the

top of the chimney pipe. Drill four 1/8-inch diameter holes

through the adapter, and into the chimney top. Insure

that you are in fact, drilling into the metal on the chimney.

Install the Termination Cap onto the Outlet Connector.

Refer to Figures 3 and 4.

5. Pull the flex pipe down through the ceiling support

box, until it protrudes approximately 3-inches. Connect

the flex pipe to the Chimney Inlet Connector by slipping

it into the sleeve on the top side of the Connector. Use

three sheet metal screws, to assemble these two parts.

6. Push the flex pipe back up into the ceiling support,

center the Chimney Inlet Connector, and attach it to the

support box, or decorative sleeve for double wall solid

packed pipe, with the sheet metal screws furnished. The

holes in the connector are pre-punched. Refer to Figure

5.

7. The connection between the appliance and the Chimney

Inlet Connector may be completed with sections of black

direct vent pipe, together with an adjustable length.

4DT-MCK (Masonry Chimney Conversion Kit

)

4DT-CCK (Factory-Built Chimney Conversion Kit)

DIRECT-TEMP

®

WARNING

!

Failure to follow the instructions could cause

FIRE, CARBON MONOXIDE POISONING, OR DEATH.

If

you are unsure of installation requirements, call the Phone

Number listed on the instructions or visit www.selkirkcorp.com