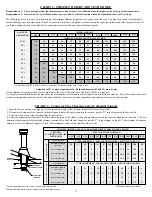

17

UNIVERSAL ROOF GUY KIT (JURGK-1)

If the chimney extends 5 ft. (1600 mm) or more above the roof deck, roof

guys are required. The Roof Guy Kit will provide lateral support to the

chimney above the roof line. The kit contains Telescoping Legs, Support

band, Roof Angle Brackets and hardware package.

The Roof Guy Kit accommodates most models of chimneys with outer

diameters ranging from 7" through 13".

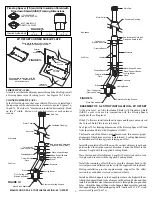

Cage

Nut

Holes used to attach

Telescoping Legs to

Support Band

Holes used to assemble

Support Band

Tab for

2” Bolt

Holes used to assemble

Support Band

Holes used to attach

Telescoping Legs to

Support Band

Figure 28

Support Band Holes Identifier

Holes for

Telescoping

Legs to Support Band

Holes for Support Band

Cage Nut

Holes for Support Band

Holes for

Telescoping

Legs to Support Band

Tab For

2” Bolt

Figure 29

Assembly of Universal

Support Band (2 Halves)

NOTE:

Different holes combination can be selected as required.

To Install:

A. Measure the outside (OD) diameter of your chimney.

B. From the single row of holes (see Figures 28 and 29), select the hole in

each half that corresponds to the outside diameter identified with the

chimney being installed. Place the two halves together. Insert an

elevator bolt through the chosen holes (Ex - for a 10” OD chimney, place

the elevator bolt through the holes identified for 10” OD). The elevator

bolt should be oriented as shown in Figure 30. Secure the center bolt with

washers and 1/4” flanged nut (see Figure 30). NOTE: On smaller

diameter chimneys the excess band material can be cut off.

Figure 30

Topview assembly of Support Band -

Elevator Bolt, Washers and Nut

Flanged Nut

Flat Washers

Support Band

Halves

Elevator

Bolt

Cage Nuts

Figure 31

Universal Support Band

formed into a circle

2” Bolt

Cage Nut

One of 2 halves

of Support Band

One of 2 halves

of Support Band

Elevator

Bolt

Flat Washer

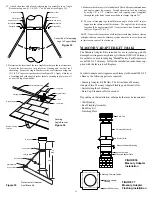

Assembly of Support Band:

C. Form the band into a circle (see Figure 31) and loosely connect tabs

using the supplied 2” bolt into the cage nut located on one of the two

formed tabs.

D. Select the hole in each half that corresponds to the OD of the chimney.

Insert an elevator bolt in each of the holes (1 per side).

E. Position the Support Band approximately two thirds of the way up the

chimney height (see Figure 35). The preferred location is next to a

joint, immediately above or below a Locking Band. Secure Support

Band by tightening the 2” bolt. NOTE: Only one chimney joint should

be above a Roof Guy Kit. An additional Roof Brace Kit may be

required for taller systems.

Assembly of Telescoping

Legs with Hose Clamp

Figure 32

Larger Diameter

Telescoping Leg

Pilot Hole for

Securing Screw

Cut Section of Larger

Telescoping Leg

Hose Clamp

Smaller Diameter

Telescoping Leg

F. Assemble the telescoping legs by sliding the supplied hose clamp over

larger diameter leg and then inserting smaller diameter leg into larger

diameter leg. Temporarily hold legs together by tightening the hose

clamp over the cut section of larger diameter leg (see Figure 32).

Repeat for the other telescoping leg assembly.

G. Place a flat washer on the elevator bolts and attach the angled end of each

of the telescoping legs to the 2 elevator bolts on the Support Band with

washer and nut (see Figure 33).