14

WARNING:

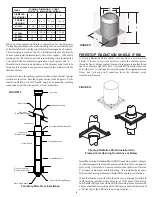

The Insulated Tee Cap must be installed and

secured in place. Failure to install could cause fire, injury or death.

Insulated

Chimney

Sections

Support

Plate

Insulated Tee Cap

Nutsert

Screw to

Secure Tee

Cap Bracket

Tee Cap

Bracket

Insulated

Tee

Support

Plate

METHOD B

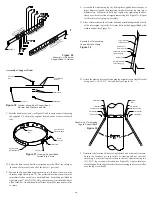

11. Ensure that the Wall Support is level, and secure to the wall

through the pre-punched holes located on the sides of each of the

support brackets using (8) #14 x 1-1/2" hex head lag screws or #10 x

1-1/2" wood screws. You can drill 5/32" pilot holes for the lag screws.

Make sure they go into solid bracing as per the requirements in Table

3 Section B and Figure 21 (B) below the prepared Wall Thimble

opening. For concrete block or poured foundation use suitable

fasteners. NOTE: For 5" to 7" diameters a choice of two (2) uppermost

mounting holes are available.

12. Place the Insulated Tee on the support Plate ensuring that the male

coupler of the Tee is facing up and the flange on the top of the Support

Plate slides into the female coupler (see Figures 24 & 26).

Insulated Tee

Cap

Tee Cap

Bracket

Securing

Screw

FIGURE 25 - Assembled Wall Support

with Tee Cap Secured in Place

FIGURE 24 - Explosion View -

Wall Support, Insulated Tee

and Tee Cap, Tee Cap

Bracket and securing Screw.

15. Insert and install the Insulated Tee Cap into the bottom of the

Support Plate opening. To secure, slide the Tee Cap Bracket into both

slots located at the front and rear of the Support Plate. Make sure the

Tee Cap Bracket is beneath the Tee Cap and the other end is exiting

through the slot at the back of the Support Plate. Secure in place by

threading the securing screw into the nutsert located on the front of

the Support Plate (see Figures 24, 25 and 26).

FIGURE 26 - Securing of Insulated Tee Cap

14. Use a non-hardening high-temperature sealant (500

°

F) to seal

around the horizontal Chimney Length where it enters through the

exterior of the Wall Thimble or the concrete wall.

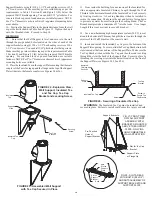

Nuts

Slot on

Support

Bracket

Support Brackets

Pre-Punched

Holes of

Support Bracket

Support Plate

w/ Flange Up

Slot for Tee Cap

Bracket

Slot on

Support

Plate

Bolts

FIG. 28 - SLOT AREAS

WITH BOLTS (#8 x 3/4")

AND NUTS ASSEMBLY OF

SUPPORT BRACKETS AND

SUPPORT PLATE

FIG. 27- FRONT VIEW

OF WALL SUPPORT

ASSEMBLY WITH

BRACKETS MOUNTED

ABOVE THE SUPPORT

PLATE - ONLY IN A

NON-COMBUSTIBLE

WALL APPLICATION

13. From inside the building, for an extension of the Insulated Tee,

slide an appropriate Insulated Chimney Length through the Wall

Thimble to the horizontal branch of the Insulated Tee. Lock securely

by twisting clockwise. A Locking Band must then be installed to

secure the connection. Make sure the nut and bolt are facing down

to prevent any water from collecting in the Locking Band. The Tee

Branch must protrude a minimum of 3" into the room. Use a longer

Length if this is not met (not to exceed 24 inches).

10. Position the Support Plate to the desired distance from the wall

as per the limits shown in Table 4 and Figure 19. Tighten the 4 nuts

onto the threaded studs. Proceed to Step 14.

Support Brackets using (8) #14 x 1-1/2" hex head lag screws or #10

x 2" wood screws. Make sure they go into solid bracing as per the

requirements in Table 3 Section B and Figure 21(B), below the

prepared Wall Thimble opening. You can drill 5/32" pilot holes. For

concrete block or poured foundation use suitable fasteners. NOTE:

For 5" to 7" diameters a choice of two (2) uppermost mounting holes

are available.