17

Level

Roof

Pitch is 3/12

3"

12" Ruler

FIGURE 37

Roof Pitch Calculation

Find the centre of the opening by dropping a plumb bob from the

inside of the roof sheathing to the centre of the leveled chimney

length below. Do the same to find the outline of the required opening

to the edge of the hole in the ceiling below. By moving the plumb

bob around the edge of the opening below (which includes the

required clearance) mark several points forming the outline of the

hole on the underside of the roof sheathing. Remember: these

measurements are in the horizontal plane. Drill pilot holes following

the marked outline.

Once you have marked and located the area where the chimney will

come through the roof, center, position and prepare the roof area by

removing shingles, shingle nails and cutting of the roofing material.

Be careful when lifting roof shingles so they do not become damaged

as they may be old or if the installation is done during cold weather.

Frame the opening to suit the pitch of the roof and allowing for a 2"

clearance to the chimney on all four (4) sides. This is done before

extending the chimney above the roof.

Ensure that you have the proper Roof Flashing by checking your roof

pitch using a level and two rulers (see fig. 37) or by using a roof pitch

card.

The AAF Roof Flashing is for roof pitches from 0/12 to 6/12.

The AF2 Roof Flashing is for roof pitches from 6/12 to 12/12.

ROOF FLASHING

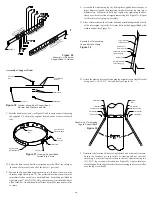

Slide the Roof Support down over the chimney section until the

support brackets rest on the roof or floor. Use a level against or on

top of the Chimney Length to ensure that the chimney is plumb

prior to the final position of the support brackets. Tighten the

support band around the chimney with the nuts and bolts supplied,

then secure the collar by screwing the 6 supplied sheet metal screws

through the holes in the support band and into the chimney casing.

Center the chimney in the joist or rafter opening (ensure that the 2"

required air space clearance is met) and nail or screw the Roof Support

to the roof or floor using the 12 x 3-1/2” spiral nails supplied or 12 #8

x 2" wood screws into a solid base.

Install additional Chimney Sections and lock together by turning

clockwise until the two sections lock together tightly - continue in

this manner until the desired height is achieved. The use of Locking

Bands on all Chimney Lengths above the roof is highly recommended

for added safety and stability when exposed to windy conditions.

NOTE:

The male coupler of each chimney length must point up.

RAFTER RADIATION SHIELD (RRS)

A Rafter Radiation Shield (RRS) must be installed where the chimney

is enclosed immediately below the roof line as shown in

figure 26. An example of this is when the attic space of a house is being

used as living space (ie. bedroom, guestroom etc.). It must also be

installed when height restrictions will not allow the use of the Attic

Insulation Shield (AIS) and the chimney has been enclosed with an

enclosure around the chimney.

Attach the support brackets to the shield (through one of the three

pre-punched holes) such that once the shield is installed, the shield

protects both the upper and lower parts of the roof joist framing (See

figures 35 & 39).

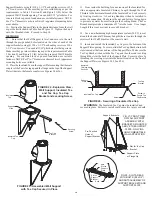

Rafter Radiation Shield Assembly

FIGURE 35

Shield

Bracket

Screw

ROOF SUPPORT (RS)

The Roof Support may be used on a floor, ceiling or roof and adjusts

to any roof pitch. It may be used above an offset to support the offset

or as a supplementary support when the chimney height exceeds that

of the primary support. It will also provide additional support for a

Cathedral Ceiling installation when more than 3 feet is above the roof.

The Roof Support will support a total height of 50 feet of chimney

sections of which 20 feet may be suspended beneath it. All chimney

sections below the support must be secured with Locking Bands.

The Roof Support is mounted directly on the roof sheathing with

FIGURE 36

Roof Support Assembly

Nut

Lock Washer

Support Band

Carriage Bolt

Support

Bracket

Attach the support brackets to the support band with the 1/2” nuts,

bolts and lock washers. The lock washer is placed between the band

and support bracket to provide proper spacing as shown in Figure 27.

7. 4 painted ceiling trim angles (2 short & 2 long) are supplied with

fastening screws to finish off the Support Box at the ceiling level. The

2 long pieces are trimmed off to match the pitch of the ceiling.

its feet (support bracket) resting over rafters or a framed opening to

form a solid base. Frame a rectangular roof opening to provide a 2"

minimum air space clearance from combustible materials. The framing

dimension is measured in the horizontal plane.

6. Chimney sections (15 ft max.) installed below the Cathedral Ceiling

Support are locked together from below by turning clockwise until

tightly locked together with each joint being secured by a Locking

Band.These lengths can be painted to match the connector pipe with

a high temperature heat resistant paint. To improve adhesion to the

chimney, degrease, clean, prime before painting. Follow the paint

manufacturer's instructions.