18

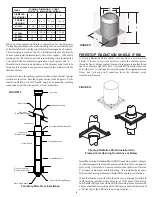

Apply a non-hardening high temperature silicone caulking just above

the top of the Flashing cone on the chimney casing. Slide the collar

down the chimney until it contacts the Flashing and the caulking.

Tighten the nut and bolt and apply additional caulking above the

Storm Collar as required. After the installation check to ensure that

the ventilation slots are not obstructed (See Figure 38).

Shingles

Ventilated Flashing

Nails

Roof Flashing Installation

FIGURE 38

Framed

Enclosure

Rafter Radiation

Shield

Flashing

Storm Collar

Ventilation Slots

Raincap

if the chimney, Flashing and Storm Collar may be painted with a heat

resistant rust proofing paint when enclosing of the chimney is not

possible or if exposed to wind driven ocean spray. Salty humid air

causes metal to corrode faster than air with normal humidity. This

will extend its life and improve the appearance and could match the

roof shingles. To improve adhesion to the SuperVent/SuperPro

Chimney, degrease, clean and prime before painting. Follow the paint

manufacturer's instructions.

Continue adding Chimney Lengths until the proper height is achieved

as per Figure 1 requirements (also Chart 2 on page 22 of these

instructions). Install Locking Bands at all chimney joints above the

roof line for added security. Install the Rain Cap and lock it in place

by turning clockwise until snug.

FIGURE 39

Storm Collar/Flashing Installation

If the chimney extends 5 feet or more above the roof line (measured

from the upper slope), a Roof Guy Kit is required. The Roof Guy Kit

provide lateral support to the chimney above the roof line. The kit

contains Telescoping Legs, draw band, Roof angle Brackets and

hardware package.

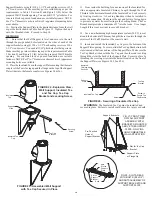

Wrap the Storm Collar around the chimney above the Flashing.

Secure the ends together loosely with the nut and bolt supplied.

NOTE: A Rubber Boot Flashing Kit (URBFK)

is available as an option

for passing through a corrugated or metal roof. See separate instruc-

tions packaged with the Rubber Boot Flashing Kit. On metal or steep

roofs, it is recommended that an ice deflector or chimney cricket

fabricated from heavy-guage galvanized steel be installed. This will

protect the Chimney and the Flashing by routing the snow load and

ice around the chimney.

Apply a bead of

silicone caulking

along the seam

of the cone

where it meets

the plate

Apply a bead of

silicone caulking

along the back

seam of the

cone

Assemble Chimney Sections through the roof opening and Flashing.

Ensure that all sections are locked together by turning clockwise until

the sections lock tightly. Install Locking Bands to secure the chimney

sections. Fasten the flashing with 2 screws or nails. Before commit-

ting to a final position of the Flashing and chimney, ensure the entire

Chimney system is level and plumb and the required 2" air space

clearance is maintained from all combustible material before perma-

nently nailing and sealing the Flashing to the roof.

Nail the Flashing to the roof deck (also under the shingles) along the

upper edge and down each side with 12 nails with neoprene washers

or cover the nails with a suitable non hardening waterproof caulking.

Seal the shingles to the plate in the same manner. As a precaution,

you may apply a bead of caulking along all seams of the Flashing.

WARNING:

Slide the top edge (nearest the roof peak) of the Flashing under the

roof shingles. At least half of the Flashing should be UNDER the

shingles and the bottom edge OVER the shingles to provide a

watershed. Trimming off the shingles may be neccessary around the

cone of the Flashing for a better fit. Do not nail the flashing to the roof

yet as adjustments may be required.

DO NOT BLOCK THE VENTILATION

SLOTS ON THE FLASHING.

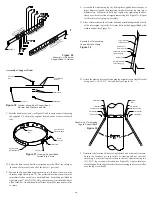

ROOF GUY INSTALLATION (JURGK-1)

The Roof Guy Kit accommodates most models of chimneys with outer

diameters ranging from 7" through 13".

NOTE:

Different holes combination can be selected as required.

Holes used to attach

Telescoping Legs to

Support Band

Holes used to assemble

Support Band

Support Band Holes Identifier

Tab for

2” Bolt

Holes used to assemble Support

Band

Holes used to attach

Telescoping Legs to

Support Band

Cage

Nut

Figure 28

To Install:

A. Measure the outside (OD) diameter of your chimney.

B. From the single row of holes (see Figures 28 and 29), select the hole in

each half that corresponds to the outside diameter identified with the

chimney being installed. Place the two halves together. Insert an elevator

bolt through the chosen holes (Ex - for a 10” OD chimney, place the

elevator bolt through the holes identified for 10” OD). The elevator bolt

should be oriented as shown in Figure 30. Secure the center bolt with

washers and 1/4” flanged nut (see Figure 30). NOTE: On smaller diameter

chimneys the excess band material can be cut off.