21

“Creosote and Soot - Formation and Need for

Removal”

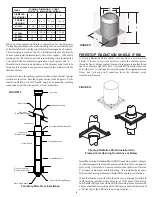

MAINTENANCE AND CLEANING OF CHIMNEY:

WARNING:

DO NOT USE FUEL MATERIALS CORROSIVE TO

THE CHIMNEY LINER SUCH AS DRIFTWOOD,

PLASTICS, CHEMICALLY TREATED WOOD, ETC.

If chemical cleaner is used to assist in the cleaning of your SuperVent/

SuperPro chimney, make sure it is a product which is non corrosive.

It does not replace the need for a mechanical cleaning. The optimal

method for cleaning a chimney is by a mechanical brushing of the

chimney in conjunction with a complete evaluation of the system by

a certified chimney sweep.

CHIMNEY FIRES AND WHAT TO DO ABOUT THEM

Your SuperVent/SuperPro is not intended or designed for use as a

combustion or fire chamber. It is very easy to overfire your

woodburning appliance with kindling, scrap lumber, brush or any

fast burning fuel. This can produce flames and high temperatures all

the way up the chimney, and may cause chimney damage. The

following materials should not be burned in your woodburning

appliance: pressure treated lumber, rail road ties, salt water driftwood

or plastic. Burning such materials may lead to severe corrosion of the

appliance and the chimney system.

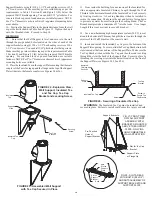

If you see your appliance or the stove pipe glowing red, you are

risking chimney damage, or a fire. The creosote may be burning inside

the chimney. If you see flames coming out the top, you are either

overfiring or there is a chimney fire.

If the fire in your appliance has gotten out of control, or if you suspect

a chimney fire for any reason, follow these steps:

1. Immediately close all dampers and/or air entrance openings to your

appliance. This includes doors on Franklin type stoves. Block off

fireplace openings.

2. Alert your family to the possible danger.

3. Inspect your appliance and chimney surroundings for possible

fire. If in doubt, alert your Fire Department.

4. Do not continue to use your appliance until it and your chimney

have been thoroughly inspected. Overheating can cause metal parts

to expand, buckle and crack. If you are not certain, have a certified

wood technician or certified chimney sweep disassemble all parts so

they can be inspected and replaced.

5. Do not use salt or water on the fire in your appliance. Salt is

corrosive and water will cause a dangerous steam explosion. You

might be able to control the fire by using ashes, sand or baking soda.

Baking soda is an ingredient used for dry chemical fire extinguishers.

6. After a chimney fire, when it is safe to do so, check internal

locations such as the attic and under the roof and keep watching for

two or three hours. There may be delayed smoldering and subsequent

ignition, even if the fire inside the chimney has been controlled.

Chimney and flue pipe are particularly susceptible to off-season

condensation. The incomplete combustion of wood produces acids

which, when combined with moisture, are corrosive. During the

heating season, corrosion tends not to occur because the heat in the

system evaporates the condensation of any water vapour that may

be formed.

Warm, moist air during the summer months passes slowly through

the heating system. It makes any remaining ash or creosote moist

and soggy. Corrosion of steel occurs where these deposits remain.

Off-season corrosion can be reduced considerably if the system is

thoroughly cleaned after the last fire of the heating season. Where

coal is burned, the system must be thoroughly cleaned within 48

hours of shutting down the system for the season and all soot be

removed from the chimney system. This should be the most careful

cleaning the system receives all year. Air inlets should be closed and

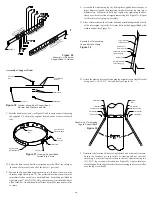

With a new installation, the chimney should be inspected frequently

(every 2 wks) to determine the rate of creosote formation. When

familiar with the appliance and chimney characteristics, the chimney

should be inspected at least once every 2 months during the heating

season to determine if a creosote or soot build-up has occurred.

Check spark arrestor screens at least every 2 to 4 weeks. If the spark

arrestor becomes clogged with creosote, it should be cleaned or

replaced.

If creosote or soot has accumulated, it should be removed to reduce

the risk of a chimney fire. Depending on the rate of build-up (as little

as 1/16") and as you learn what is going on in the chimney, you can

adjust your cleaning schedule accordingly. Every chimney flue and

flue pipe shall be inspected annually and cleaned as often as may be

necessary to keep the chimney and flue pipe free from dangerous

accumulation of combustible deposits.

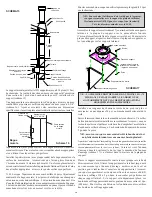

How you burn wood in your stove or fireplace directly affects the

formation of creosote. Use more dry kindling and paper first to warm

up the chimney system to a temperature between 350° to 500° F. Burn

hot, bright fires and fire each load hot. It is important to load your

appliance properly and to avoid smoldering fires. Fast, effective

start-ups are important, as is the moisture content of the wood being

burned. If your wood is not completely seasoned, split your wood

in smaller pieces instead of larger ones. Ideally, the moisture content

of your firewood should be between 18 to 22%. A good investment

in assisting you in monitoring your system is a surface thermometer

for single wall stove pipe or a probe thermometer for double wall stove

pipe. Ensure that only low sulphur content coal (1% or less) such as

anthracite is burned.

When wood is burned slowly, it produces tar and other organic

vapors, which combine with expelled moisture to form creosote. The

creosote vapors condense in the relatively cool chimney flue of a

slow-burning fire. As a result, creosote residue accumulates on the

flue lining. When ignited, this creosote creates a chimney fire with

extremely high temperatures.

sealed if necessary to prevent the constant flow of air through the

system.

Contact a professional certified chimney sweep for chimney cleaning

services and advice if you have any doubts about your ability to

clean your chimney system or if the task is too large. To visually

inspect the chimney, remove the Rain Cap by simply using the twist-

lock feature. Care should be taken not to disengage any lower

chimney sections. This will permit the insertion of a flashlight for

inspection and a properly sized plastic chimney cleaning brush. A

metal brush may scratch the liner and lead to premature corrosion.

The Insulated Tee Cap (if so equipped) can be removed by twisting

anti clockwise or by removing the securing bolt and Tee Cap Bracket

to inspect or clean from the bottom. Be sure to replace the Tee Cap

or Insulated Tee Cap, Tee Cap Bracket/Securing Bolt and Rain Cap

when you are finished inspecting/cleaning the chimney.

The need for chimney maintenance depends on the kind of appliance

and how it is operated. Gas and oil-burning appliances need very

little, but wood-burning appliances may need a great deal of chimney

maintenance.