Page 11

4

4

5

5

18

21

23

27

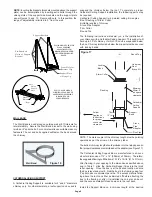

UNIVERSAL ROOF BRACE KIT

If the chimney extends 5 feet (1.5m) or more above the roof deck,

a Universal Roof Brace Kit is required. The Universal Roof Brace

Kit contains 2 telescopic legs, brackets, band strap and hardware

package. The band strap is wrapped around the chimney and

the two telescopic legs bolted to the roof brackets.

The Flashing and Storm Collar may be painted to match the roof

shingles. This will extend its life and improve the appearance. The

chimney may be painted also with a HEAT RESISTANT paint. To

improve adhesion to the chimney, degrease, clean and prime

before painting. Follow the paint manufacturer’s instructions.

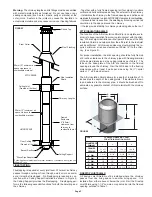

Continue adding chimney lengths until the proper height is

achieved (see Figure 1 and Chart 2). Install a Round Top. The

Round Top prevents entry of moisture which might lead to prema-

ture deterioration of the chimney.

On metal or steep roofs, it is recommended that an ice deflector

or “cricket” fabricated from heavy-guage galvanized steel be

installed. The wedge-shaped deflector is installed 2” from the

chimney on the upper slope. Its function is to split ice and snow

as they slide down the roof, preventing damage to the chimney.

This is not a supplied item. Contact your dealer or a sheet

metal fabrication shop in your area for your custom ice deflector.

This also should be painted with a suitable metal paint by

following the paint manufacturer’s instructions.

Once you have marked and located the area where the chimney

will come through the roof, center, position and prepare the roof

area by removing shingles, shingle nails and cutting the roofing

material. Frame a RECTANGULAR opening to suit the pitch of

the roof and ensure that a 2” (50mm) clearance is maintained to

combustibles on all four (4) sides. This is done before extending

the chimney above the roof. Do not nail the flashing to the roof at

this time as ajustments may be required.

Slide the top edge (nearest the roof peak) of the flashing under

the roofing shingles. At least half of the flashing (top and sides)

should be UNDER the shingles and the lower end OVER the

shingles to provide a watershed. Trimming off the shingles may

be neccessary around the cone of the flashing for a better fit. On

existing roof application, lower a chimney length into the flashing

opening and twist lock in place and secure with a Locking Band.

Ensure that the chimney is level and plumb before nailing the

flashing to the roof.

Nail the flashing to the roof deck (also under the shingles) along

the upper edge and down each sides with 12 nails with neoprene

washers or cover the heads with a suitable non hardening

waterproof caulking. Seal the shingles to the plate in the same

manner. As a precaution, apply a bead of caulking along all

seams of the flashing as per Figure 21.

Apply a non-hardening high temperature silicone caulking just

above the top of the flashing cone where it meets the chimney

casing. Slide the Storm Collar through the applied caulking and

place into its final position to ensure a waterproof joint. Apply

additional caulking above the Storm Collar as required.

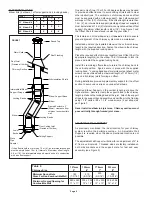

Two (2) pockets must be formed to attach the telescopic legs

(use Figure 23 and the Selection Chart below as guide).

Tab “A” is formed at one end by bending the strapping band

(clearing the first hole). The number of holes counted away from

Tab “A” (including the first hole) will identify the location of the

first pocket. Attach at this location the “U” bracket by inserting a

bolt through and securing with the supplied nut.

To form Tab “B” count the holes away from the “U” bracket. At this

location a bolt is inserted into the holes creating the other pocket.

Fasten the larger diameter section of the telescopic leg to the

“U” bracket using the bolt and nut.

FIGURE 22

Eye Bolt

Clamp

Storm Collar

Flashing

Locking Band

Nut & Bolt

Round Top

Band Strap

Telescopic Leg

Nails

FIGURE 23

UT/ST

Inside Diameter

# Holes from "Tab A" for

the "U" Bracket

# holes from "U" Bracket

to bolt hole in tab "B"

Hole/Tab Selection Chart

"U" Bracket

(1st Pocket)

Tab "A"

Tab "B"

Bend the strapping of

Tab "A" and "B" to form

2nd pocket and cut off

excess material

5”

6”

7”

8”