Page 12

B

C

A

4. Always secure all single wall flue pipe joints with a minimum

of 3 screws.

5. Obtain proper attachment parts for the appliance end and for

the entry to the chimney.

6. Locate or support the flue pipe to avoid contact of damage.

7. Caps or plugs for single wall tees should be secured

against falling out and designed so they can’t leak creosote

or rain.

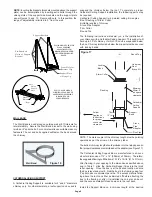

The band is clamped around the chimney and the two legs

bolted to the roof. Position the band approximately two thirds of

the way up the chimney height. The preferred location for the

band is next to a joint, immediately above or below a locking

band and fasten the other telescopic leg to Tab “A” and Tab “B”

using the bolt and nut provided.

Secure the bottom end of each telescopic legs to the roof brack-

ets and the roof brackets to the roof with supplied hardware as

shown in Figure 24. The two legs of the brace assembly should

form an angle of about 60 degrees to give support to the chimney

in all directions. Keep bottom ends equal distance from the

chimney and at approx. at the same elevation, on the high side of

the sloped roof. Ensure that the lags are anchored in rafters and

not just the roof deck. Seal the roof with a suitable non-hardening

waterproof sealant. After the legs are attached securely to the

roof brackets and to the band, tighten the eye bolt which locks

the two tubes together fixing the position of the telescopic legs.

Figure 24

SPARK ARRESTER

Use a spark arrester if you have a shingle roof or live in a for-

ested area. If the chimney is used for venting a gas appliance,

use a spark arrester to keep birds out.

The Spark Arrester is made of flexible expanded metal mesh.

Each size is cut to fit the appropriate size Round Top.

Wearing safety gloves, fit the bolt with one nut and place the

mesh between the dome and the skirt of the round top. It should

be midway between the inner wind band and the outer edges.

Do not place the screen directly against the wind band.

Once the Screen is wrapped around the band, secure it in place

with the 2nd bolt and nut.

TYPE HT ROUND TOP

Attach the Type HT Round Top to the chimney by sliding it over

the chimney length. ensure that the three (3) vertical tabs are

located on the outside of the chimney length and that the

Round Top sits flush on the top surface of the length. Wrap the

band snug to the bottom of the 3 tabs and secure in place with

the supplied nut and bolt.

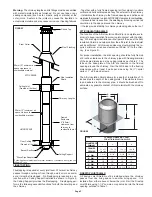

The connection of a single wall base tee or single wall flue pipe

or double wall flue pipe to the insulated chimney must be secured

with the screws supplied in the Support carton. The use of a

stove pipe adapter is recommended with the first length, this will

provide a positive connection between the insulated chimney

and the appliance connector. The Stove Pipe Adapter is inserted

into the female end of the first insulated chimney length and

extends beyond the ceiling support approximately 32mm (1-1/

4”). For a Cathedral Support and Wall Support application, the

stove pipe adapter is inserted into the female end of the exposed

chimney length and extend into the room and held in place with

the finishing collar secured with 4 screws which is used to

attach the stove pipe adapter to the finishing collar.

Install inter-connecting flue pipe following the appliance

manufacturer’s instructions, and appropriate building code

requirements keeping in mind that the flue pipe run should be

as short and straight as possible. All joints should be secured

in place with three (3) sheet metal screws.

Besides following the appliance instructions for flue pipe, other

rules that should be taken into account:

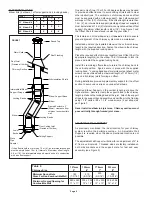

To comply with the National Building Code of Canada the single

wall base tee can be installed with a 229mm (9”) minimum air-

space clearance between connnecting single wall material and

combustible products provided that the flue gas temperature does

not exceed 400° C (750° F) (most oil fired appliances). Other-

wise, the minimum air space clearance must be 450mm (18”).

Refer to the appliance installation instructions for the proper chim-

ney requirements.

STOVE PIPE ADAPTER:

Connect only to low heat (liquid fuel or gas fired) appliances

with continuous flue gas temperatures below 540° C (1000° F).

When installing a factory-built fireplace refer to the fireplace in-

stallation instructions for the proper chimney requirements.

1. Never enclose single wall flue pipe, even at 18 inches clear-

ance.

2. Never run it through ceilings or floors, or windows.

3. Don’t use single wall flue pipe outdoors.

Ensure that

the lags are

anchored in

rafters rather

than the

sheathing

Tighten the

eye bolt which

locks the

two tubes

together fixing

the position of

the telescopic

legs

Roof Bracket Secured to Roof

C h i m n e y

Dia.

5 ”

6 ”

7 ”

8 ”

FIGURE 25

A

7 ”

8 ”

9 ”

1 0”

B

10 ”

12 ”

14 ”

16 ”

C

5 ”

5-1/2”

6-1/4”

7 ”